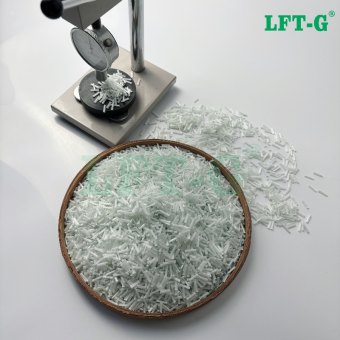

High-content long glass fiber LGF modified nylon PA66 Long Glass fiber Reinforced Polyamide nylon PA66 has extremely high mechanical properties. Excellent long-term heat resistance, dimensional stability, can replace ordinary aluminum alloy materials, and the cost is lower than metal materials.

-

Xiamen LFT Nylon series Polyamide 66 Long Glass Fiber Reinforced Thermoplastic ResinPolyamide, which is also known by the trade name, Nylon, has excellent heat resistant properties, especially when combined with additives and filler materials. In addition to this, Nylon is very resistant to abrasion. Xiamen LFT offers a wide range of temperature-resistant nylons with many different filler materials. About PA66-LGF compounds Nylon 6,6, also written as nylon 6-6, nylon 66, or nylon 6/6, is a more crystalline version of nylon 6. It is also referred to as polyamide 66 or PA 66. It has improved mechanical properties due to its more ordered molecular structure. Nylon 66 for machining has improved temperature resistance and lower rates of water absorption when compared to standard nylon 6. The advantages of nylon 6,6 are that the yield strength is higher than nylon 6 and nylon 610. It has high strength, toughness, rigidity, and low coefficient of friction in a wide temperature range. In addition, it is oil resistant and resistant to chemical reagents and solvents. However, PA66 has strong hygroscopicity and poor dimensional stability, which limits its application. In order to obtain nylon 66 engineering material with higher strength, it should be modified by glass fiber reinforcement. The mechanical properties of long glass fiber reinforced nylon 66 (LGFR-PA66) are obviously better than those of short glass fiber reinforced nylon 66 (SGFR-PA66), and the molding processing performance is also better. It can be molded by various molding methods such as injection molding and compression molding, and complex components can also be formed. Therefore, long glass fiber reinforced nylon 66 can be widely used in building materials, aerospace, electronic devices, furniture and other fields, especially in the automotive industry application market. The production process of long glass fiber reinforced nylon 66 is different from that of short glass fiber reinforced nylon 66. The short glass fiber reinforced nylon 66 particle is chopped under the friction and shearing of screw and barrel, and the short glass fiber reinforced nylon 66 particle is obtained with the length of glass fiber monofilament about 0.5mm. The length of some glass fiber monofilament in the final product is lower than the critical length of reinforcement, and the glass fiber is easy to be extracted from the nylon 66 matrix when the product is stressed. The strength of glass fiber is not fully utilized, and the mechanical properties of the product are not high. Long glass fiber reinforced nylon 66 has better reinforcement effect and dimensional stability, and the rigidity, tensile, bending, impact resistance and fatigue resistance of the manufactured products are better, and the service life is longer. Materials Details Number PA66-NA-LGF Color Natural color or Customized Length 6-25 mm Package 25kg/bag MOQ 25kg Lead time 2-15 days Port of Loading Xiamen Port Trade terms EXW/FOB/CFR/CIF/DDU/DDP About Xiamen LFT Xiamen LFT Composite Plastic Co.,LTD was established in 2009, is a brand-name global suppliers of long fiber reinforced thermoplastic materials integrating product research & developmen (R&D), production and sale marketing. Our LFT products have passed the ISO9001&16949 system certification and have obtained lots of national trademarks and patents, covering the fields of automotive, military parts and firearms, aerospace, new energy, medical equipment, power wind energy, sports equipment, etc. LFT long fiber reinforced thermoplastic engineering materials,compared to ordinary short fiber reinforced thermoplastic materials (fiber length is less than 1-2 mm), the LFT process produces thermoplastic engineering material's fibers in lengths of 5-25 mm. The long fibers are impregnated with the resin through a special mold system to obtain long strips that are fully impregnated with the resin ,and then cut to the length as required. The most used base resin is PP, by PA6, PA66, PPA,PA12,MXD6,PBT,TPU,PPS, ABS,PEEK, etc. Conventional fibers include glass fiber, carbon fiber. Depending on the end use, the finished products can be used for injection molding,extrusion, molding, etc., or directly used for plastic instead of steel and thermoset products.

- PA66 PA 6.6 Enginering materials

- excellent heat resistance with filler

- injection molding products light weight

- car parts toy home applance use

- modified plastic manufacturer can be customized

- can be recylced GFRP GF30

Tags :

-

Xiamen LFT Polyamide 6,6 Long Glass Fiber Reinforced Thermoplastic Resin Nylon pelletsAbout Polyamide 66 Nylon 6,6 or PA 66 Is the most used polyamide High melting points, Abrasion resistance, Poor chemical resistance, and High water absorption What Are the Physical Properties of Polyamide? The most notable physical property of polyamide is its excellent wear resistance due to its low coefficient of friction created by its self-lubricating properties. Below is a list of other physical polyamide properties: Low density. Temperature resistance. Good impact resistance. High strength. Flexibility. What Are the Chemical Properties of Polyamide? The chemical property that makes polyamides stand out from other plastics is its excellent chemical resistance. Other chemical properties of polyamides are listed below: Very susceptible to osmosis. Nontoxic. Chemically stable. Nonflammable. About Long Glass Fiber LFT® is A LGF or LCF compound , through Centerfill manufacturing method which Offers exceptional Properties for weight and Cost reduction. With pellet length of 7-25mm and a range of 20%-70% of LGFor LCF content , LFT® Products family consist of Tailor made solutions to the Industry’s vast requirements , such as: LFT® - Fulfills heat stability requirements. LFT® - Offer Climate resistant Properties including UV resistance. LFT® - Ultra Performance & safety , with exceptional impact resistance Features, especially at low temperatures. LFT® - Cost Effective P.s. Centerfill manufacturing method:Centerfill uses our proprietary technology to introduce glass roving (GFR), which consists of several thousand filaments, into an impregnating device and melt the thermoplastic resin, uniformly impregnating between the filaments and then cutting them into pellets. Manufacture. What Are the Applications of Polyamide Long Fiber Reinforcement? 1. Engineering Plastics Engineering plastics are broadly defined as plastics that have better-performing properties than more widely used plastics. In the case of polyamides, these properties are good wear resistance, high strength, chemical resistance, and impact resistance. These better properties mean polyamides are used for helmets, bearings, supports, piping, and protective equipment. 2. Automotive Industry Polyamides are used in the automotive industry for their light weight, low cost, and good mechanical properties. Specific automotive applications include engine air intakes, car gate, engine covers, pulley tensioners, fuel lines, fuel pumps, lights, and vehicle trim. 3. Electrical and Electronics For a long time, polyamides have been the material of choice for electrical connectors. This is because electrical connectors, as well as other non-conductive electrical parts, require high heat resistance which polyamide can offer. Polyamide is also chosen due to its low cost, easy formability, high strength, and electrical insulation properties. They are frequently used to replace metal for applications in which light weighting, improved impact strength, elastic modulus, and material strength are required. Certifications & Lab Other Polyamide materials you may interested: PA12-LGF PPA-LGF About Xiamen LFT iamen LFT Composite Plastic Co.,LTD was established in 2009, is a brand-name global suppliers of long fiber reinforced thermoplastic materials integrating product research & developmen (R&D), production and sale marketing. Our LFT products have passed the ISO9001&16949 system certification and have obtained lots of national trademarks and patents, covering the fields of automotive, military parts and firearms, aerospace, new energy, medical equipment, power wind energy, sports...

- Polyamide 66 PA66 glass fiber reinforcement

- lft gf30 instead metal and steel lightweight

- easy to process good price

- high flexibility and durability composites plastic

- car frame injection molding

- hot sell compounds

Tags :

-

LFT-G High toughness Polyamide 66 with filler Long Glass Fiber PolymersPolyamide 66 + LGF They are frequently used to replace metal for applications in which light weighting, improved impact strength, elastic modulus, and material strength are required.

- PA66 nylon 66 resin

- Automotive fittings parts plasitc

- instead metal new materials Polyamide

- GFRP glass fiber reinforcement compounds

- High performance lighter weight Pa

- China factory made PA66 pellets

Tags :

-

LFT-G modified Polyamide 66 filled long glass fiber compoundsPA66-LGF Information PA66 is one of the most produced and widely used polyester series products. It has high grain size, excellent tensile properties, bending properties, tensile strength and other material mechanical properties, and its excellent ultra-low temperature characteristics and organic chemical properties. It is a class of rubber products with wide range of application, stable characteristics, good mechanical properties, high quality insulation, low density, easy processing and molding, self-extinguishing, and good wear resistance. Therefore, it is widely used in vehicles, electronic and electrical, chemical materials, industrial equipment, instrument panels, construction projects and other industries. However, it has high water absorption, poor alkali resistance, dry ultra-low temperature impact, low compressive strength and easy to deform after absorbing moisture, which affects the reliability of goods specifications. People have improved PA66 in a variety of ways, adding PA66 chemical fiber is one of them. After adding glass fiber, its impact force, heat deformation, material mechanical properties, molding processability and acid resistance are significantly improved. Glass fiber is a class of functional raw materials with high quality characteristics. This utility model has the advantages of low cost, non-combustibility, high temperature resistance, acid resistance, high tensile strength, high impact compressive strength, low tensile strength, high quality insulation properties, high quality insulation properties, etc. It is usually used as a raw material to improve organic chemical polymers or functional materials and composites. The most important hazard of proportional limits to raw materials is mechanical properties. The material mechanical properties of modified PA66 are also related to the composition of glass fibers. The tensile strength, bending strength and impact compression strength of PA66 increase with the glass fiber composition after the addition of PA66 chemical fibers. The tensile and flexural strengths of the managed system increased linearly, but the glass fiber composition was 30%. The trend of increasing tensile and flexural strengths showed some improvement. The results show that PA66 can produce a reasonable page layer, which can reasonably transfer the ground stress between the matrix and page, and thus improve the compressive strength of the matrix. PA66-LGF TDS The datasheet was tested by Xiamen LFT, for your reference only. PA66-LGF Application Suitable for many fileds, other application you can ask for our technical advice. Details Number Color Length Sample MOQ Port of Loading Delivery time Payment terms PA66-NA-LGF30 Original color (can be customized) 12mm (can be customized) Available 25kg Xiamen Port 7-15 days after shipment Discussed Xiamen LFT composite plastic Co., Ltd Xiamen LFT composite plastic Co., Ltd. is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) & Long Carbon Fiber Series (LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm in length. The company's long-fiber continuous infiltration reinforced thermoplastics have passed ISO9001 &16949 system certification, and the products have obtained lots of national trademarks and patents. We will offer you: 1. LFT&LFRT material technical parameters and leading edge design 2. Mold front design and recommendations 3. Provide technical support such as injection molding and extrusion molding.

- Low warpage electronic appliance

- self owing pa66 pellets thermoplastic resin

- high strength and high toughness reinforced pa66 pellets

- best long glass fiber pa66 lgf30 granules

- PA66 6 twin screw lgf pellets

- Long Fiber PA66 granules Application

Tags :

-

Xiamen LFT Polyamide 66 Reinforced resin Long Glass fiberReinforced Polyamide (nylon) resin PA66 Long Glass fiber is a mechanical component shield for high rigidity and dimensional stability, and is widely used in mechanical and electrical parts used in the electrical and electronic industry.

- Glass fibre reinforced polyamide thermoplastic resin

- Long Fiber reinforced Thermoplastics

- Thermoplastic Polymer low warpage

- Nylon Long glass fiber high quality made in China

- Application electrical parts PA66 Polyamide

Tags :

-

Xiamen LFT Polyamide 66 reinforced material long glass fiber 20%-60% modified plasticWhat is PA66? PA66, abbreviation of Polyamide 66, chemical name polyadiptyl adiptyl diamine, commonly known as nylon 66. Is a colorless transparent semi-crystalline thermoplastic polymer, widely used in automobiles, electronic appliances, mechanical instruments, industrial parts and other industries. What is PA66-LGF? However, due to the large absorbency of nylon itself, poor acid resistance, low impact strength of dry state and low temperature, and easy deformation after water absorption, the dimensional stability of the product is affected, so that its application range is limited to some extent. In order to improve the above shortcomings, expand its application field, and better meet the requirements of performance, people adopt a variety of methods to modify PA66 plastic, so as to improve the impact property, thermal deformation property, forming processing property and chemical corrosion resistance. Because the specific strength and Young's modulus of glass fiber (LGF) are 10~20 times larger than that of PA66, the linear expansion coefficient is about 1/20 of that of PA66, the water absorption is close to zero, and it has good heat and chemical resistance, glass fiber filling is the most commonly used enhancement modification method of PA66. PA66 is the variety with the highest mechanical strength and the most widely used in PA series. Because of its high crystallinity, it has high rigidity and heat resistance. TDS Translucent or opaque opalescent crystalline polymer with plasticity. It has excellent wear resistance, self lubricity and high mechanical strength. Application 1. The automobile industry Because of its excellent heat resistance, chemical resistance, strength and convenient processing, nylon 66 has been widely used in the automobile industry. At present, it can be used in almost all parts of the automobile, such as the engine parts, electrical parts and body parts. The engine part includes the intake system and the fuel system, such as the engine cylinder head cover, throttle, air filter machine housing, vehicle air horn, vehicle air conditioning hose, cooling fan and its housing, water inlet pipe, brake oil tank and cover, and so on. Body parts include: car fender, rear view mirror frame, bumper, dashboard, luggage rack, door handle, wiper bracket, seat belt buckle, interior decoration and so on. Car electric appliances such as electric control doors and Windows, connectors, crisper, cable tie wire. 2. Electronic and Electrical industries PA66 can produce electronic and electrical insulation parts, precision electronic instrument parts, electrical lighting appliances and electronic and electrical parts, can be used to make rice cookers, electric vacuum cleaners, high-frequency electronic food heaters, etc. PA66 has excellent solder resistance and is widely used in the production of junction boxes, switches and resistors. Flame retardant grade PA66 can be used for color TV wire clip, fixing clip and focusing knob. 3. Machinery transportation and machinery and equipment industry PA66 can be used for door handles of passenger cars and brake joint discs of freight cars. Other products such as insulation washer, baffle seat, turbine, propeller shaft, screw propeller and sliding bearing on ship can also be made with PA66. High impact resistance nylon 66 can also be made pipe pliers, plastic molds, radio control body, etc. Unreinforced grade nylon 66 is usually used to manufacture nuts, bolts, screws, nozzles, etc. with low creep and no corrosion. Reinforced grade nylon 66 used in the production of chains, conveyor belts, fan blades, impeller and scaffolding fixed foot buckle. Details Number Color Length MOQ Package Sample Delivery time Port of Loading PA66-NA-LGF30 Original color 12mm 25kg 25kg/bag Available 7-15 days after shipment Xiamen Port Frequently asked questions 1. How to choose the fiber content of the product? Is the larger product suitable for higher fiber content material? A. This is not absolute. The content of glass fiber is not more is better. The suitable content is just to meet the requirements of each products. 2. Can products with appearance requirements be made of long-fiber materials? A. The main feature of LFT-G thermoplastic long glass fiber and long carbon fiber is to show the mechanical properties. If the customer has bright or other requirements for the appearance of the product, it needs to be evaluated in combination with specific products. 3. How to choose the reinforcement method and length of the material when using long fiber reinforced thermoplastic material? A. The selection of materials depend on the requirements of the products. It is necessary to assess how much the content is enhanced and how much length is more appropriate, which are depending on the performance requirements of the products.

- Polyamide 66 lgf filling lgf can be recycled green materials

- long glass fiber polyamide66 good price

- pa66 lgf30 thermoplastic resin polymers

- long fibre reinforced thermoplastics

- long fiber compounds pa66 CAR PARTS

- polyamide 6.6 lgf30 PA66 GF30

Tags :

-

Xiamen LFT-G Polyamide 66 long glass fiber reinforced thermoplastic compounds high strengthWhat is PA66? PA66, abbreviation of Polyamide 66, chemical name polyadiptyl adiptyl diamine, commonly known as nylon 66. Is a colorless transparent semi-crystalline thermoplastic polymer, widely used in automobiles, electronic appliances, mechanical instruments, industrial parts and other industries. What is PA66-LGF? However, due to the large absorbency of nylon itself, poor acid resistance, low impact strength of dry state and low temperature, and easy deformation after water absorption, the dimensional stability of the product is affected, so that its application range is limited to some extent. In order to improve the above shortcomings, expand its application field, and better meet the requirements of performance, people adopt a variety of methods to modify PA66 plastic, so as to improve the impact property, thermal deformation property, forming processing property and chemical corrosion resistance. Because the specific strength and Young's modulus of glass fiber (LGF) are 10~20 times larger than that of PA66, the linear expansion coefficient is about 1/20 of that of PA66, the water absorption is close to zero, and it has good heat and chemical resistance, glass fiber filling is the most commonly used enhancement modification method of PA66. PA66 is the variety with the highest mechanical strength and the most widely used in PA series. Because of its high crystallinity, it has high rigidity and heat resistance. TDS of Polyamide 66 filling LGF Translucent or opaque opalescent crystalline polymer with plasticity. It has excellent wear resistance, self lubricity and high mechanical strength. Application 1. The automobile industry Because of its excellent heat resistance, chemical resistance, strength and convenient processing, nylon 66 has been widely used in the automobile industry. At present, it can be used in almost all parts of the automobile, such as the engine parts, electrical parts and body parts. The engine part includes the intake system and the fuel system, such as the engine cylinder head cover, throttle, air filter machine housing, vehicle air horn, vehicle air conditioning hose, cooling fan and its housing, water inlet pipe, brake oil tank and cover, and so on. Body parts include: car fender, rear view mirror frame, bumper, dashboard, luggage rack, door handle, wiper bracket, seat belt buckle, interior decoration and so on. Car electric appliances such as electric control doors and Windows, connectors, crisper, cable tie wire. 2. Electronic and Electrical industries PA66 can produce electronic and electrical insulation parts, precision electronic instrument parts, electrical lighting appliances and electronic and electrical parts, can be used to make rice cookers, electric vacuum cleaners, high-frequency electronic food heaters, etc. PA66 has excellent solder resistance and is widely used in the production of junction boxes, switches and resistors. Flame retardant grade PA66 can be used for color TV wire clip, fixing clip and focusing knob. 3. Machinery transportation and machinery and equipment industry PA66 can be used for door handles of passenger cars and brake joint discs of freight cars. Other products such as insulation washer, baffle seat, turbine, propeller shaft, screw propeller and sliding bearing on ship can also be made with PA66. High impact resistance nylon 66 can also be made pipe pliers, plastic molds, radio control body, etc. Unreinforced grade nylon 66 is usually used to manufacture nuts, bolts, screws, nozzles, etc. with low creep and no corrosion. Reinforced grade nylon 66 used in the production of chains, conveyor belts, fan blades, impeller and scaffolding fixed foot buckle. Details Number Color Length MOQ Package Sample Delivery time Port of Loading PA66-NA-LGF30 Original color or Customized 6-25mm 25kg 25kg/bag Available 7-15 days after shipment Xiamen Port Frequently asked questions 1. How to choose the fiber content of the product? Is the larger product suitable for higher fiber content material? A. This is not absolute. The content of glass fiber is not more is better. The suitable content is just to meet the requirements of each products. 2. Can products with appearance requirements be made of long-fiber materials? A. The main feature of LFT-G thermoplastic long glass fiber and long carbon fiber is to show the mechanical properties. If the customer has bright or other requirements for the appearance of the product, it needs to be evaluated in combination with specific products. 3. How to choose the reinforcement method and length of the material when using long fiber reinforced thermoplastic material? A. The selection of materials depend on the requirements of the products. It is necessary to assess how much the content is enhanced and how much length is more appropriate, which are depending on the performance requirements of the products.

- Polyamide 66 lgf filling lgf high rigidity

- long glass fiber polyamide66 instead metal steel

- pa66 lgf30 car parts and other products

- long fibre reinforced thermoplastics nylon 66

- long fiber compounds pa66 cut down cost

- polyamide 6.6 lgf30 GF

Tags :

-

LFT-G Polyamide 66 with addition long glass fiber 20%-60% reinforced plastic as a replacement for metalWhat is Polyamide 66 materials? PA66, abbreviation of Polyamide 66, chemical name polyhexanediylhexanediamine, commonly known as nylon 66. It is a colorless transparent semi-crystalline thermoplastic polymer, widely used in automotive, electrical and electronic appliances, mechanical instruments and meters, industrial parts and other industries. However, due to the high water absorption, poor acid resistance, low impact strength in dry state and low temperature, and easy to deform after absorbing water, which affects the dimensional stability of the products, the scope of its application has been limited to a certain extent. In order to improve the above shortcomings, expand its field of application, and better meet the requirements for the use of performance, people use a variety of methods to modify PA66, in order to improve the impact, heat deformation, molding and processing performance and chemical corrosion resistance of PA66 plastic. As the specific strength and Young's modulus of glass fiber (GF) is 10-20 times larger than PA66, the coefficient of linear expansion is about 1/20 of PA66, the water absorption rate is close to zero, and there is good heat and chemical resistance, etc., so the glass fiber filling is the most commonly used means of enhancement and modification of PA66. Polyamide 66 fillin long glass fiber compounds Why do we use LFT plastics instead of metal? Many components that are currently manufactured in metal can be produced at lower cost and lower weight in high strength plastics. Compared to metals, plastics offer a number of significant advantages: • Faster production cycles • Lower investment in equipment and tooling • Elimination of finishing operations, such as machining or painting • No corrosion problems • Tighter tolerances • Easier assembly What is the difference between Long glass fiber and Stardard glass fiber? Long glass fiber (LGF) typically contain glass fibers with lengths of 10 to 12 mm, versus 0.7-mm fibers in standard glass-reinforced compounds. In the composite material made of fibers is sheared or pulled, the fibers are pulled out from the matrix, such a pulling process is conducive to the absorption of energy provided by the loading, the longer the fibers are within a certain length, the greater the absorption of energy, and the more significant its strength. And in the same volume amount, due to the longer the single fiber, the fewer the number of fiber roots, the less stress concentration generated at the fiber end, the more difficult the destruction of the material. From the results of practical application feedback, the various properties of long glass fiber reinforced thermoplastic composites are more excellent than Standard glass fiber. In addition, glass fiber reinforced composites in the friction process, the fiber body plays an important role in lubrication, long glass fiber can be much more sustainable, stable lubrication, so the coefficient of friction is lower, less wear, and the formation of the abrasive debris is finer. Because of these advantages, long glass-fiber reinforced thermoplastic composites perform better in real-world applications without fear of high frequencies and high loads. What is the advantages of Polyamide 66? Nylon 6/6 is composed of a molecular structure of higher order than Nylon 6, heightening Nylon 6’s positive characteristics: higher tensile strength and stiffness, better dimensional stability, and a higher melting point. Nylon 6/6 has a high lubricity and resistance to hydrocarbons; and exceptionally balanced strength, ductility, and heat resistance. As strong as it is independently, adding fillers, fibers, lubricants, and impact modifiers can increase Nylon 6/6’s strength times five and stiffness times ten. TDS of 30% long stand fiber glass reinforced Polyamide 6.6 All TDS with 20%-60% fiber specification, please aks technologists What are the applications of Nylon 66 filling long stand fiber glass pellets? Frequently asked questions Q. Does long glass fiber and long carbon fiber injection have special requirements for injection molding machines and molds? A. There are certainly requirements. Especially from the product design structure, as well as the injection molding machine screw nozzle and mold structure injection molding process must consider the requirements of long fiber. Q. Using a long fiber reinforced thermoplastic material, will it block the die hole due to the long length of the fiber or not? A. When using long glass fiber or long carbon fiber, it is necessary to evaluate whether the product is suitable for LFT-G. If the product is too small or the dispensing is not suitable for long fiber materials. The long fiber itself has requirements for mold nozzle. Q. How to choose the rei...

- engineering thermoplastics PA66

- long glass fiber reinforced thermoplastic resin pa66

- heat deflection temperature pa66 gf

- Nylon 66 comounds more dystaline

- injection molded high stiffness and tensile

- gf filled plastic pa66 natural color

Tags :

-

Xiamen LFT-G Polyamide 66 nylon materials reinforced plastic high mechanical properties customized color and lengthPolyamide 66 Nylon 66 (PA66) has excellent mechanical properties, processing performance and corrosion resistance, after flame retardant modification of PA66 can be widely used in automotive, electronics, machinery and other fields. With the wide application of nylon in different fields, the requirements for its performance have been taken to the next level. However, PA66 has high crystallinity and fast crystallization speed, and is prone to warpage defects during injection molding process. Especially for glass fiber reinforced nylon 66, due to the anisotropic arrangement of glass fibers inside the material, it is easy to cause different shrinkage rates in all directions, which further aggravates the warping deformation. Long glass fiber reinforced composites Glass fiber is an excellent performance of inorganic non-metallic materials, mostly used for reinforcing plastics. Mainly silica as raw material, add specific metal oxides mineral raw materials melted at high temperature, molten glass liquid flow through the leakage nozzle out of the role of high-speed pulling gravitational force is drawn and rapid cooling and curing into a very fine continuous fibers, the diameter of a few microns to more than twenty microns. Glass fiber is divided into short glass fiber, long glass fiber according to the shape. Short glass fiber: length less than 6mm, cross-section is round, in the material distribution disorder, anisotropy. Long glass fiber: length between 6-25mm, orderly distribution in the material, isotropic. Short Glass Fiber Nylon: Processability, rigidity and strength are improved, and floatation is less likely to occur during injection molding compared to long glass fiber nylon. Long glass fiber reinforced nylon: less anisotropic shrinkage compared to short glass fiber, reducing the effect of warpage. The rigidity, abrasion resistance, aging resistance, and heat resistance are stronger than those of short glass fiber reinforced nylon. Datasheet Application About us Xiamen LFT Composite Plastic Co.,LTD was established in 2009, is a brand-name global suppliers of long fiber reinforced thermoplastic materials integrating product research & development(R&D), production and sale marketing. Our LFT products have passed the ISO9001&16949 system certification and have obtained lots of national trademarks and patents, covering the fields of automotive, military parts and firearms, aerospace, new energy, medical equipment, power wind energy, sports equipment, etc.

- Polyamide 66 composite

- Polyamide 66 lgf filling lgf

- pa66 nylon plastic raw materials

- PA66 composite fiber car parts

- New high performance thermoplastic resin

- general grade pa66 compounds

Tags :

-

LFT-G Polyamide 6 nylon materials filling glass fiber 20%-60% high mechanical properties sample availablePolyamide 66 filling long glass fiber PA66 is one of the most produced and widely used polyester series products. It has high grain size, excellent tensile properties, bending properties, tensile strength and other material mechanical properties, and its excellent ultra-low temperature characteristics and organic chemical properties. It is a class of rubber products with wide range of application, stable characteristics, good mechanical properties, high quality insulation, low density, easy processing and molding, self-extinguishing, and good wear resistance. Therefore, it is widely used in vehicles, electronic and electrical, chemical materials, industrial equipment, instrument panels, construction projects and other industries. However, it has high water absorption, poor alkali resistance, dry ultra-low temperature impact, low compressive strength and easy to deform after absorbing moisture, which affects the reliability of goods specifications. People have improved PA66 in a variety of ways, adding PA66 chemical fiber is one of them. After adding glass fiber, its impact force, heat deformation, material mechanical properties, molding processability and acid resistance are significantly improved. Glass fiber is a class of functional raw materials with high quality characteristics. This utility model has the advantages of low cost, non-combustibility, high temperature resistance, acid resistance, high tensile strength, high impact compressive strength, low tensile strength, high quality insulation properties, high quality insulation properties, etc. It is usually used as a raw material to improve organic chemical polymers or functional materials and composites. The most important hazard of proportional limits to raw materials is mechanical properties. The material mechanical properties of modified PA66 are also related to the composition of glass fibers. The tensile strength, bending strength and impact compression strength of PA66 increase with the glass fiber composition after the addition of PA66 chemical fibers. The tensile and flexural strengths of the managed system increased linearly, but the glass fiber composition was 30%. The trend of increasing tensile and flexural strengths showed some improvement. The results show that PA66 can produce a reasonable page layer, which can reasonably transfer the ground stress between the matrix and page, and thus improve the compressive strength of the matrix. Datasheet for reference Test Certifications Factory Xiamen LFT composite plastic Co., Ltd Xiamen LFT composite plastic Co., Ltd. is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) & Long Carbon Fiber Series (LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm length. The company's long-fiber continuous infiltration reinforced thermoplastics have passed ISO9001&16949 system certification, and the products have obtained lots of national trademarks and patents. Main products

- pa66 nylon fill lgf home appliance parts

- pa66 compounds for electronic parts

- low warpage PA66 composite glass fiber

- thermoplastic resin pa66 with fiber

- electronic appliance part materials pa66 long fiber

- pa66 nylon filling long fiber white

Tags :

-

LFT-G modified nylon66 PA66 filling long glass fiber compounds toughen resistance grade for electronic appliancesPA66-LGF Information PA66 is one of the most produced and widely used polyester series products. It has high grain size, excellent tensile properties, bending properties, tensile strength and other material mechanical properties, and its excellent ultra-low temperature characteristics and organic chemical properties. It is a class of rubber products with wide range of application, stable characteristics, good mechanical properties, high quality insulation, low density, easy processing and molding, self-extinguishing, and good wear resistance. Therefore, it is widely used in vehicles, electronic and electrical, chemical materials, industrial equipment, instrument panels, construction projects and other industries. However, it has high water absorption, poor alkali resistance, dry ultra-low temperature impact, low compressive strength and easy to deform after absorbing moisture, which affects the reliability of goods specifications. People have improved PA66 in a variety of ways, adding PA66 chemical fiber is one of them. After adding glass fiber, its impact force, heat deformation, material mechanical properties, molding processability and acid resistance are significantly improved. Glass fiber is a class of functional raw materials with high quality characteristics. This utility model has the advantages of low cost, non-combustibility, high temperature resistance, acid resistance, high tensile strength, high impact compressive strength, low tensile strength, high quality insulation properties, high quality insulation properties, etc. It is usually used as a raw material to improve organic chemical polymers or functional materials and composites. The most important hazard of proportional limits to raw materials is mechanical properties. The material mechanical properties of modified PA66 are also related to the composition of glass fibers. The tensile strength, bending strength and impact compression strength of PA66 increase with the glass fiber composition after the addition of PA66 chemical fibers. The tensile and flexural strengths of the managed system increased linearly, but the glass fiber composition was 30%. The trend of increasing tensile and flexural strengths showed some improvement. The results show that PA66 can produce a reasonable page layer, which can reasonably transfer the ground stress between the matrix and page, and thus improve the compressive strength of the matrix. PA66-LGF TDS The datasheet was tested by Xiamen LFT, for your reference only. PA66-LGF Application Suitable for many fileds, other application you can ask for our technical advice. Details Number Color Length Sample MOQ Port of Loading Delivery time Payment terms PA66-NA-LGF30 Original color (can be customized) 12mm (can be customized) Available 25kg Xiamen Port 7-15 days after shipment Discussed Xiamen LFT composite plastic Co., Ltd Xiamen LFT composite plastic Co., Ltd. is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) & Long Carbon Fiber Series (LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm in length. The company's long-fiber continuous infiltration reinforced thermoplastics have passed ISO9001 &16949 system certification, and the products have obtained lots of national trademarks and patents. We will offer you: 1. LFT&LFRT material technical parameters and leading edge design 2. Mold front design and recommendations 3. Provide technical support such as injection molding and extrusion molding.

- self owing pa66 pellets

Tags :

-

lft-g PA66 reinforced material long glass fiber 30% specification Polyamide66 modified plasticWhat is PA66? PA66, abbreviation of Polyamide 66, chemical name polyadiptyl adiptyl diamine, commonly known as nylon 66. Is a colorless transparent semi-crystalline thermoplastic polymer, widely used in automobiles, electronic appliances, mechanical instruments, industrial parts and other industries. What is PA66-LGF? However, due to the large absorbency of nylon itself, poor acid resistance, low impact strength of dry state and low temperature, and easy deformation after water absorption, the dimensional stability of the product is affected, so that its application range is limited to some extent. In order to improve the above shortcomings, expand its application field, and better meet the requirements of performance, people adopt a variety of methods to modify PA66 plastic, so as to improve the impact property, thermal deformation property, forming processing property and chemical corrosion resistance. Because the specific strength and Young's modulus of glass fiber (LGF) are 10~20 times larger than that of PA66, the linear expansion coefficient is about 1/20 of that of PA66, the water absorption is close to zero, and it has good heat and chemical resistance, glass fiber filling is the most commonly used enhancement modification method of PA66. PA66 is the variety with the highest mechanical strength and the most widely used in PA series. Because of its high crystallinity, it has high rigidity and heat resistance. TDS Translucent or opaque opalescent crystalline polymer with plasticity. It has excellent wear resistance, self lubricity and high mechanical strength. Application 1. The automobile industry Because of its excellent heat resistance, chemical resistance, strength and convenient processing, nylon 66 has been widely used in the automobile industry. At present, it can be used in almost all parts of the automobile, such as the engine parts, electrical parts and body parts. The engine part includes the intake system and the fuel system, such as the engine cylinder head cover, throttle, air filter machine housing, vehicle air horn, vehicle air conditioning hose, cooling fan and its housing, water inlet pipe, brake oil tank and cover, and so on. Body parts include: car fender, rear view mirror frame, bumper, dashboard, luggage rack, door handle, wiper bracket, seat belt buckle, interior decoration and so on. Car electric appliances such as electric control doors and Windows, connectors, crisper, cable tie wire. 2. Electronic and Electrical industries PA66 can produce electronic and electrical insulation parts, precision electronic instrument parts, electrical lighting appliances and electronic and electrical parts, can be used to make rice cookers, electric vacuum cleaners, high-frequency electronic food heaters, etc. PA66 has excellent solder resistance and is widely used in the production of junction boxes, switches and resistors. Flame retardant grade PA66 can be used for color TV wire clip, fixing clip and focusing knob. 3. Machinery transportation and machinery and equipment industry PA66 can be used for door handles of passenger cars and brake joint discs of freight cars. Other products such as insulation washer, baffle seat, turbine, propeller shaft, screw propeller and sliding bearing on ship can also be made with PA66. High impact resistance nylon 66 can also be made pipe pliers, plastic molds, radio control body, etc. Unreinforced grade nylon 66 is usually used to manufacture nuts, bolts, screws, nozzles, etc. with low creep and no corrosion. Reinforced grade nylon 66 used in the production of chains, conveyor belts, fan blades, impeller and scaffolding fixed foot buckle. Details Number Color Length MOQ Package Sample Delivery time Port of Loading PA66-NA-LGF30 Original color 12mm 25kg 25kg/bag Available 7-15 days after shipment Xiamen Port Frequently asked questions 1. How to choose the fiber content of the product? Is the larger product suitable for higher fiber content material? A. This is not absolute. The content of glass fiber is not more is better. The suitable content is just to meet the requirements of each products. 2. Can products with appearance requirements be made of long-fiber materials? A. The main feature of LFT-G thermoplastic long glass fiber and long carbon fiber is to show the mechanical properties. If the customer has bright or other requirements for the appearance of the product, it needs to be evaluated in combination with specific products. 3. How to choose the reinforcement method and length of the material when using long fiber reinforced thermoplastic material? A. The selection of materials depend on the requirements of the products. It is necessary to assess how much the content is enhanced and how much length is more appropriate, which are depending on the performance requirements of the products.view more

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文