item no.:

ABS-NA-LGFPayment:

Discussedproduct origin:

ChinaColor:

Natural color or Customizedshipping port:

XiamenLead Time:

2-10 working days

What is ABS Injection Molding?

ABS (Acrylonitrile Butadiene Styrene) injection molding is one of the most popular methods for manufacturing ABS plastic products. ABS is a thermoplastic polymer that is durable and easy to work with. Injection molding is a process that involves injecting molten ABS into a mold cavity. The ABS part cools and is ejected. Injection molding is fast and efficient, and it can be used to create a wide variety of ABS products. Very few manufacturing technologies can achieve the same scale at the low costs offered by injection molding.

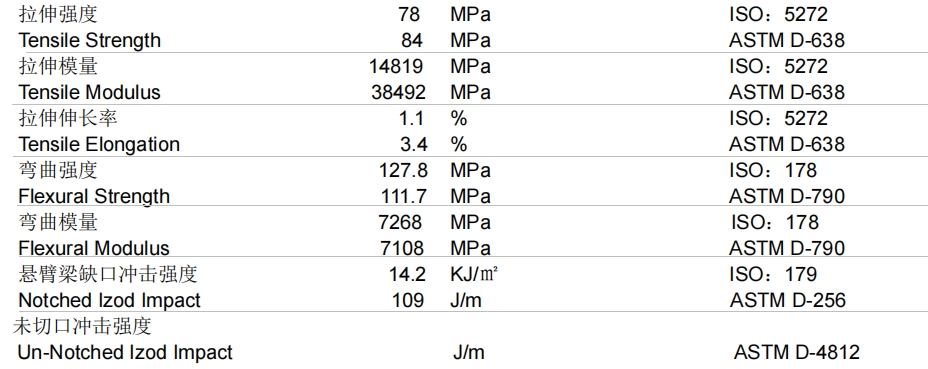

ABS with 30% LGF

Why is ABS Used in Injection Molding?

ABS is widely used in injection molding because of its desirable properties. These include high strength, low melting temperature, recyclability, and good resistance to chemicals and heat. It is also relatively easy to process and can be molded into a variety of shapes and sizes. As a result, ABS is an ideal choice for applications in which strength and durability are required, such as: automobile parts, household appliances, tools, and medical devices. Overall, ABS is a versatile and popular choice for injection molding.

What Are the Applications of ABS Injection Molding?

ABS is used in many different industries. Some common industries and their relevant applications are listed below.

Consumer Products: ABS is widely used in the consumer industry. Typical products include Electronic parts and so on. ABS produces a smooth, shiny surface that is impervious to dirt impregnation. ABS will react well to the inclusion of pigments and can be easily painted or even electroplated if desired.

Construction Industry: ABS is used for housings on many power tools due to its durability. Power outlet fittings are also often manufactured from ABS.

Automotive industry: ABS is typically used for parts such as: dashboards, seat belt parts, door trim, and bumpers due to its low weight, durability, and strength.

Company Advantages

Excellent quality. As replacement of metal and steel.

Own-factory. 500-800 tons of production per month.

Customization. From length to color or additives.

Self laboratory. Provide TDS and COA for every batch.

Fast shipping. Fast shipping to all capital cities or ports.

Favorable price. Free to get price.

Experienced team. With over 20 years experience expert team to provide assistance.

Full service. Through product discussion, performance analysis, composite selection, composite pellet production, after-sales tracking to injection molding techniques.

FAQ

Q: Can ABS Be Recycled?

A: Yes, ABS can be recycled. It is 100% recyclable.

Q: Is ABS Plastic Harmful?

A: ABS plastic is not harmful in its typical uses. It is a petroleum-based plastic that is generally safe in its solid form, releasing no known carcinogens.

Q. How to choose the reinforcement method and length of the material when using long fiber reinforced thermoplastic material?

A: The selection of materials depend on the requirements of the products. It is necessary to assess how much the content is enhanced and how much length is more appropriate, which are depending on the performance requirements of the products.

Talk to an expert now

Email: sales02@lfrtplastic.com

WhatsApp: +86 139 5009 5727