-

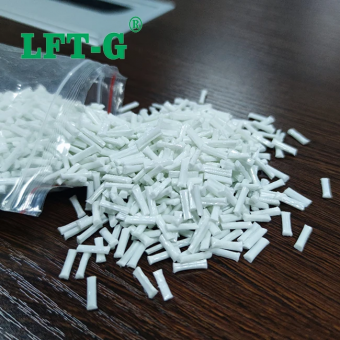

New Materials LGF PBT High Toughness for Widely UseOur Long Glass Fiber Reinforced PBT is a high-performance thermoplastic composite material combining the dimensional stability and thermal resistance of PBT with the strength and durability of long glass fibers. It is ideal for structural parts that require excellent mechanical strength, thermal stability, and electrical insulation.view more

-

New Materials LGF TPU High Tensile for Widely UseOur TPU Long Glass Fiber Reinforced Material is a high-performance thermoplastic solution that blends the flexibility of TPU with the strength of long glass fibers. This innovative material delivers enhanced mechanical performance while maintaining excellent elasticity and surface aesthetics — making it ideal for applications where durability meets design.

- tpu recycle

- tpu plastic pellets

- china tpu supplier

- glass fiber filled tpu

- tpu pellets

- tpu resin

Tags :

-

New Materials LGF Polyamide 12 Nylon for Structural ApplicationsOur Long Glass Fiber Reinforced PA12 offers exceptional mechanical strength, impact resistance, and chemical stability — making it the ideal material for precision parts used in demanding environments. With a naturally low water absorption rate and excellent dimensional stability, this advanced composite ensures reliability even under extreme conditions.

- gfrp price per kg

- engineering use nylon

- injection molding nylon

- pa12 resin

- pa12 for sale

- wholesale pa 12

Tags :

-

New Materials LGF Polyamide 66 Nylon for Structural ApplicationsOur PA66 Long Glass Fiber Reinforced Material is a high-performance thermoplastic composite developed for applications demanding superior mechanical strength, dimensional stability, and heat resistance. Ideal for metal replacement and high-load structural components.view more

-

Advanced LGF Polyamide 6 Nylon for Structural ApplicationsOur PA6 Long Glass Fiber Reinforced Material is engineered to deliver exceptional strength, thermal stability, and impact resistance—making it the ideal alternative to metal for lightweight, high-performance components across multiple industries.view more

-

Advanced LGF Homopolymer PP for Structural ApplicationsOur Homopolymer Polypropylene Long Glass Fiber Reinforced Material delivers excellent stiffness, structural strength, and dimensional stability — all while keeping weight and cost low. This material is specifically developed for injection-molded parts that demand rigidity and long-term durability.

- best fiberglass resin

- glass fiber-reinforced high-density PP

- pp gf white

- good price pp plastic

- China enhanced PP resin

- glass fiber filler

Tags :

-

Advanced LGF Copolymer PP for Structural ApplicationsOur Copolymer Polypropylene Long Glass Fiber Reinforced Material combines cutting-edge copolymer polypropylene with premium long glass fibers to create an incredibly durable, high-performance composite. Engineered for demanding industries, it offers superior strength, stability, and resistance in extreme conditions.view more

-

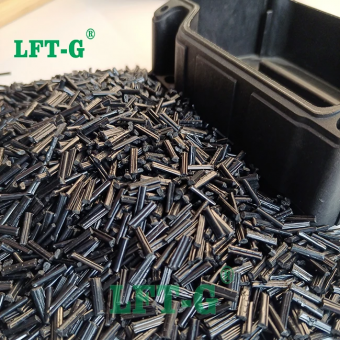

Reinforcing PEEK with Long Carbon Fibers High Strength CompoundsOur PEEK (Polyether Ether Ketone) long carbon fiber composite material is an advanced high-performance thermoplastic engineered for applications requiring exceptional mechanical properties, chemical resistance, and thermal stability. By reinforcing PEEK with long carbon fibers, this composite achieves outstanding strength, stiffness, and durability, making it an ideal choice for demanding industrial applications.

- Plastic PEEK with filler

- carbon fibre material properties

- carbon reinforced composites

- thermoplastic cfrp

- china carbon fiber plastic

- plastic compounds

Tags :

-

Advanced engineering thermoplastic Polyamide 12 Long Carbon FiberOur PA12 long carbon fiber reinforced composite material is an advanced engineering thermoplastic designed to meet high-performance application requirements. By incorporating long carbon fibers into the polyamide 12 (PA12) matrix, this composite achieves exceptional strength, impact resistance, and lightweight properties while maintaining superior dimensional stability and chemical resistance.

- Plastic nylon with filler

Tags :

-

High Strength Plastic Copo PP CFRTR Carbon Fiber Filler Injection MoldingLFT-G's high-performance copolymer polypropylene (PP) long carbon fiber composite is engineered to deliver outstanding mechanical strength, impact resistance, and dimensional stability. This material is ideal for applications requiring lightweight yet durable solutions, offering superior performance compared to conventional short fiber-reinforced PP.

- PP CF 30

Tags :

-

Flame Retardent V0 PPS Long Carbon fiber PelletsOur PPS Long Carbon Fiber Reinforced Composite is a high-performance engineering thermoplastic designed for injection molding applications requiring exceptional strength, thermal stability, and chemical resistance. This advanced material offers outstanding mechanical properties and dimensional stability, making it ideal for demanding industries such as automotive, aerospace, electronics, and industrial equipment.view more

-

High Impact Resistance Polyamide 66 Carbon Fiber filledThe main advantages of nylon 6 are its stiffness and resistance to abrasion. Moreover, this material has excellent impact strength, wear resistance, and electrical insulating properties.

- pa6 vs pa66

- pa66 30 fv

- pa66-cf30 battery

- pa66 cf30 material

- pa66 filament

- nylon factory china

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文