-

LFT Long Glass Fiber Reinforced PBT Compounds Injection MoldingPolyphthalamide is a high-performance resin and member of the nylon family with exceptional thermal, mechanical, and physical properties. It is hygroscopic, opaque, semicrystalline, and can be used in plastic injection molding. Most PPA are filled with glass fiber or carbon fiber to enhance stiffness for high-temperature applications. As a result, PPA is often used in applications in place of metal or higher-priced thermoplastic.

- High-Performance PBT Materials

- PBT Composite Materials for Industrial Applications

- PBT Thermoplastic for High-Temperature Parts

- PBT Long Glass Fiber for Manufacturing

- High-Strength PBT Long Fiber Composites

- Sustainable PBT Thermoplastics

Tags :

-

LFT Long Glass Fiber Reinforced PPA Compounds Special NylonPolyphthalamide is a high-performance resin and member of the nylon family with exceptional thermal, mechanical, and physical properties. It is hygroscopic, opaque, semicrystalline, and can be used in plastic injection molding. Most PPA are filled with glass fiber or carbon fiber to enhance stiffness for high-temperature applications. As a result, PPA is often used in applications in place of metal or higher-priced thermoplastic.

- PPA Materials for Aerospace Applications

- PPA Composites for Automotive Parts

- OEM PPA Composite Materials

- PPA for Electrical Components and Devices

- PPA Reinforced Plastic for Structural Applications

- PPA Reinforced Thermoplastic

Tags :

-

LFT Long Fiber Reinforced Polyphenylene Sulfide Compounds Flame RetardantLFT®PPS-NA-LGF is glass reinforced PPS compound, which is filled with glass fiber based on the PPS resin. The characteristic of PPS compounds includes good mechanical properties, high rigidity, high creep resistance, high temperature resistance, flame resistance, chemical resistance, excellent electrical insulation properties, arc resistance, low water absorption, low mold shrinkage, easy processing, good dimensional stability, and radiation resistance.

- PPS Long Fiber Composite

- PPS Glass Fiber for Industrial Use

- PPS High Strength Materials

- PPS Thermoplastic for High-Temperature

- Long Glass Fiber Reinforced PPS

- Polyphenylene Sulfide High Performance Plastics

Tags :

-

LFT Long Fiber Reinforced Nylon 12 High Performance CompoundsPA 12 (also known as Nylon 12) is a good general-use plastic with broad additive applications and is known for its toughness, tensile strength, impact strength and ability to flex without fracture. PA 12 has long been used by injection molders due to these mechanical properties. If you’re considering converting metal parts to plastic, PA12 will be a good choice.

- High Performance PA12 Materials

- Lightweight PA12 Glass Fiber Composite

- Advanced PA12 Long Fiber Materials for Manufacturing

- PA12 Fiber Reinforced Thermoplastics

- PA12 Composite Materials for Electronics

- PA12 Composite Materials Supplier

Tags :

-

LFT Long Fiber Reinforced Nylon 66 High Strength CompoundsLFT long glass fiber reinforced PA66 material offers exceptional strength, impact resistance, and dimensional stability. With its superior mechanical properties, it is ideal for high-performance applications in automotive, electronics, and industrial components, providing durability and long-term reliability.

- Advanced Reinforced Thermoplastics

- Long Fiber Reinforced Polymers (LFRP)

- Long Fiber Composite Materials for Power Tools

- Injection Molding Long Fiber Materials

- PP/PA Reinforced Composite Materials

- Durable Composite Materials for Electronics

Tags :

-

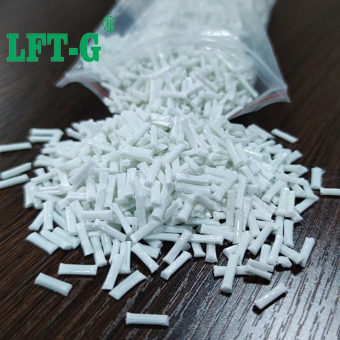

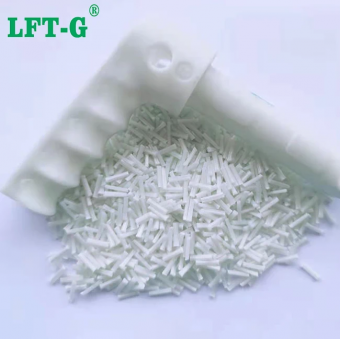

China LFT-G Nylon Polyamide 6 composite Long Glass Fiber modified plastic original colorPolyamide, which is also known by the trade name, Nylon, has excellent heat resistant properties, especially when combined with additives and filler materials. In addition to this, Nylon is very resistant to abrasion. Xiamen LFT offers a wide range of temperature-resistant nylons with many different filler materials.

- PA6 thermoplastic resin materials

- nylon 6 granules

- glass fiber reinforced plastics granules

- long fiber compounds pa6

- Injection molding plastic

- LFT-G reinforced material

Tags :

-

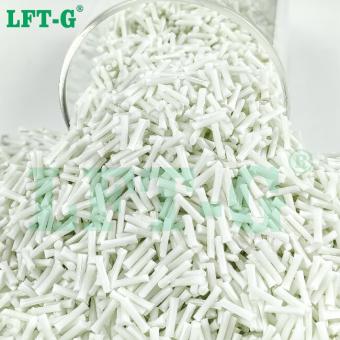

High Strength Homopolymer PP Long Glass Fiber Composite for DurabilityOur high-performance homopolymer PP long glass fiber composite offers exceptional high strength and durability, making it an ideal solution for demanding industrial applications and automotive components.

- Long Glass Fiber PP Composite

- High Strength Polypropylene

- PP Glass Fiber Reinforced Material

- Industrial PP Composite

- PP Composite for Automotive

- High-Performance Plastic Reinforcement

Tags :

-

High-Performance for Injection Molding Long Glass Fiber Reinforced PP China ManufacturerOur Glass Fiber Reinforced Polymer with High-Performance offers exceptional strength and durability, perfect for injection molding PP applications.

- Glass Fiber Reinforced Polymer

- High-Performance PP Material

- Injection Molding PP

- Copolymer Plastic Material

- Reinforced Thermoplastic

- Durable Plastic for Automotive

Tags :

-

LFT Long Fiber Reinforced PEEK High Mechanical Properties PlasticLFT long carbon fiber reinforced PEEK material offers unmatched strength, stiffness, and exceptional resistance to high temperatures and chemicals. Its superior durability and dimensional stability make it ideal for demanding aerospace, automotive, and industrial applications, where performance and reliability are crucial.

- Polyether Ether Ketone CFRP resin Composites

- China factory Polyether Ether Ketone

- long carbon fiber filled PEEK materials

- OEM ODM Manufacturer PEEK plastic

- Plastic raw matetials injection mold PEEK

- PEEK polymer black color engineering plastic

Tags :

-

LFT Long Fiber Reinforced PPS High Mechanical Properties PlasticLFT long carbon fiber reinforced PPS material combines superior thermal stability and high mechanical strength, making it perfect for high-performance applications. Its excellent resistance to wear, chemicals, and high temperatures ensures long-lasting reliability in challenging environments.

- PPS CFRP resin Composites

- China factory Polyphenylene sulfide

- long carbon fiber filled PPS materials

- OEM ODM Manufacturer pps plastic

- Plastic raw matetials injection mold pps

- pps polymer black color engineering plastic

Tags :

-

LFT Long Fiber Reinforced Nylon 12 High Mechanical Properties PlasticLFT long carbon fiber reinforced PA12 material combines outstanding strength, rigidity, and thermal stability, making it perfect for demanding applications in the automotive and industrial sectors. Its superior resistance to wear and fatigue ensures long-lasting performance, even under harsh conditions.

- PA12 CFRP resin Composites

- China factory Nylon pellets

- long carbon fiber filled polyamide 12

- OEM ODM Manufacturer Nylon plastic

- Plastic raw matetials injection mold nylon

- nylon polymer black color

Tags :

-

LFT Long Fiber Reinforced Nylon 66 High Strength CompoundsLFT long glass fiber reinforced PA66 material offers exceptional strength, impact resistance, and dimensional stability. With its superior mechanical properties, it is ideal for high-performance applications in automotive, electronics, and industrial components, providing durability and long-term reliability.view more

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文