item no.:

PPA-NA-LGFPayment:

Discussedproduct origin:

ChinaColor:

Natural color or Customizedshipping port:

XiamenLead Time:

2-10 working days

What Are Engineering Plastics?

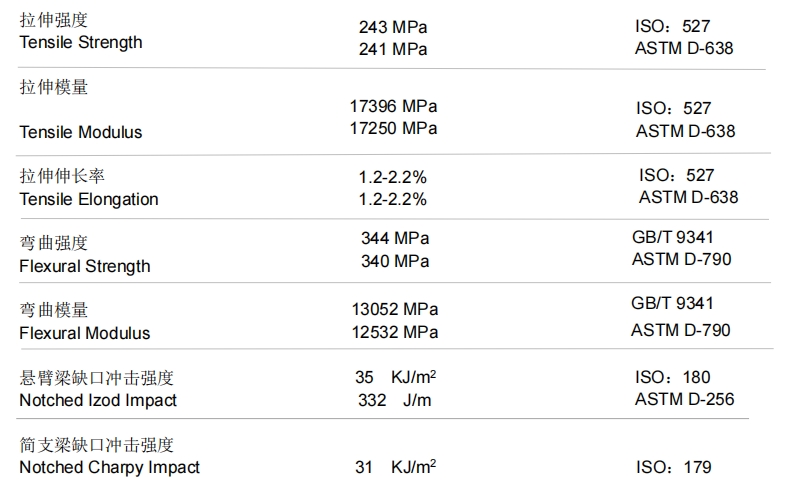

PPA with 50% LGF

What Is the Importance of Engineering Plastics?

Engineering plastics play a pivotal role in many industries, such as: automotive, aerospace, electronics, medical, and consumer goods manufacturing. Engineering plastics are known for their ability to be used in applications where metals may be too heavy, expensive, or susceptible to corrosion, and where commodity plastics lack the strength and durability required. They are durable and versatile owing to their mechanical strength and impact resistance, coupled with their desirable thermal, electrical, and chemical properties. Engineering plastics offer manufacturers an ideal balance between strength, cost, weight, and durability.

What Are the Uses of Polyphthalamide (PPA)?

Polyphthalamide has many uses. It is used for electronics and electrical, automotive, cables & wires, and many other applications.

Polyphthalamide is used chiefly as an alternative for several metal components in the industries such as automotive and others. PPA can be used for fuel & coolant lines, motor bobbin parts, pump wear rings, fuel line connectors, fuel cut-off valves, water heater manifolds, fuel modules, thermostat housings, coolant pumps, air coolers, and LED headlights.PPA enables the creation of automobile components with better mechanical strength and decreased overall vehicle weight. As a result, the use of PPA helps to lower fuel consumption.

PPA is also used for multiple electronic applications, as the high melting point of PPA allows SMD parts molded from PPA to be assembled using a lead-free soldering process. PPAs are also utilized for USB-C connectors, cable & wire protection, and LED mounts.

Other uses for PPA-based resins include gas pipes and supply lines for the oil industry.

Company Advantages

Excellent quality. As replacement of metal and steel.

Own-factory. 500-800 tons of production per month.

Customization. From length to color or additives.

Self laboratory. Provide TDS and COA for every batch.

Fast shipping. Fast shipping to all capital cities or ports.

Favorable price. Free to get price.

Experienced team. With over 20 years experience expert team to provide assistance.

Full service. Through product discussion, performance analysis, composite selection, composite pellet production, after-sales tracking to injection molding techniques.

FAQ

Q. What Is the Difference Between Polyphthalamide (PPA) and Nylon?

A. The difference between PPA and Nylon is that PPA is a type of Nylon.

- Polyamide, or Nylon, is a primary high-performance engineering thermoplastics class because of its excellent balance of properties. It is formed by condensing identical units and copolymers with different units.

- Polyphthalamide (PPA) is a semicrystalline, aromatic polyamide. It is in the polyamide, or nylon, family.

- Compared to Nylon 6/6, it is stronger, stiffer, less sensitive to moisture, and has higher thermal capabilities. In addition, it has significant resistance to chemical fatigue and mechanical creep.

Q. How to choose the reinforcement method and length of the material when using long fiber reinforced thermoplastic material?

A: The selection of materials depend on the requirements of the products. It is necessary to assess how much the content is enhanced and how much length is more appropriate, which are depending on the performance requirements of the products.

Talk to an expert now

Email: sales02@lfrtplastic.com

WhatsApp: +86 139 5009 5727