item no.:

PPS-NA-LGFPayment:

Discussedproduct origin:

ChinaColor:

Natural color or Customizedshipping port:

XiamenLead Time:

2-10 working days

Why are your pellets so long?

What’s the difference between them and short fibers?

Long fiber pellets have several significant advantages over short fiber materials, especially in terms of enhancing the mechanical properties of plastics. Our long fiber pellets are typically used to improve the strength, rigidity, and impact resistance of materials. They are longer than short fiber pellets, allowing for better dispersion in the matrix material and forming a stronger fiber network structure, which significantly enhances the material's mechanical properties, particularly in terms of tensile and bending strength.

Compared to short fibers, long fiber materials have the following distinct differences:

1. Higher strength and rigidity: Long fibers can be more evenly distributed in the material, providing better tensile strength, bending rigidity, and so on.

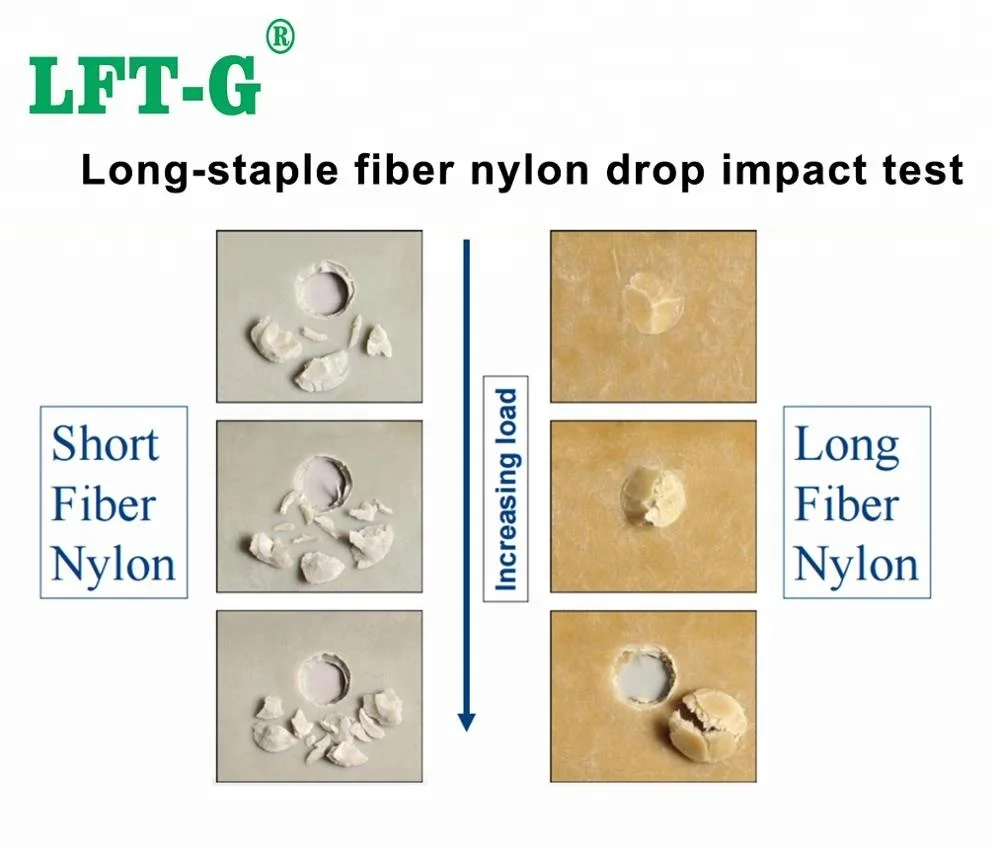

2. Stronger impact resistance: Long fibers effectively improve the material's toughness and impact resistance, making them especially suitable for industrial products that require high impact resistance.

3. Better stability: Long fiber materials offer better dimensional stability and fatigue resistance, making them suitable for applications with long-term use.

4. Applicaition: long fiber materials are suitable for high-performance applications such as automobiles, electronic devices, and household appliances, while short fiber materials are more commonly used in applications where performance requirements are not as high.

Difference between PPS and PPA

Although PPS and PPA are both high-performance engineering plastics, there are still clear differences between them in some aspects:

1. Chemical structure is different: the main chain of PPS contains sulfur atoms, and the main chain of PPA contains amide groups, which determines their differences in physical properties and chemical properties.

2. Different heat resistance: although both have excellent heat resistance, but the high temperature resistance of PPS is more prominent, can be used at higher temperatures for a long time.

3. Mechanical properties difference: PPA high temperature nylon than PPS material mechanical properties are better, with higher tensile strength (23°C to 200°C) and higher weld strength.

4. Dimensional stability and flame retardant difference: PPS water absorption is very low, has better dimensional stability than PPA; PPS flame retardant has more advantages, PPS has self-extinguishing, its flame retardant can reach UL94 V-0 level.

FAQ

Q: Does long glass fiber and long carbon fiber injection have special requirements for injection molding machines and molds?

A: There are certainly requirements. especially from the product design structure, as well as the injection molding machine screw nozzle and mold structure injection molding process must consider the requirements of long fiber.

Q. What are the main features and advantages of long fiber reinforced thermoplastics?

A: Compared with traditional short fiber materials, the main features of LFT-G thermoplastic long glass fiber and long carbon fiber are mechanical properties, high impact and tensile modulus, which are more suitable for some large products or structural load-bearing parts. It can do Injection molding, extrusion of sheets, profile pipes, etc.

Q. Are long fiber reinforced composites suitable for other processes besides injection molding?

A: In addition to injection molding, LFT long glass fiber and long carbon fiber can also be used for extrusion of sheets, profiles, pipes and molding, among which injection molding is the most common.

Advantages

Excellent quality. As replacement of metal and steel.

Own-factory. 500-800 tons of production per month.

Customization. From length to color or additives.

Self laboratory. Provide TDS and COA for every batch.

Fast shipping. Fast shipping to all capital cities or ports.

Favorable price. Free to get price.

Experienced team. With over 20 years experience expert team to provide assistance.

Full service. Through product discussion, performance analysis, composite selection, composite pellet production, after-sales tracking to injection molding techniques.