Long carbon fiber Reinforced Polyamide nylon PA12 prepared by solution impregnation process. Long carbon fiber reinforced PA12 is more important in the automotive parts, electronics and packaging industries. Can be compared with PA6 & 66 long carbon fiber modification.

-

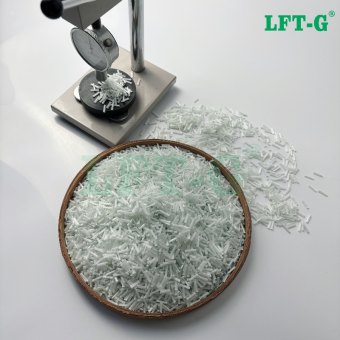

Xiamen LFT Polyamide12 filled Long Carbon Fiber composite lightweight sample availablePA12 information Long carbon chain nylon is a nylon with amide group in the main chain repeating unit of nylon molecule, and the length of methylene group between two amide groups is more than 10. We call it as long carbon chain nylon, including nylon 11, nylon 12, etc.. PA12 is nylon 12, also known as poly(dodecalactam) and poly(laurolactam), which is a kind of long carbon chain nylon. The basic raw material for polymerization is butadiene, a semi-crystalline - crystalline thermoplastic material. Nylon 12 is the most widely used long carbon chain nylon, it has most of the general properties of nylon, in addition to low water absorption, and has high dimensional stability, high temperature resistance, corrosion resistance, good toughness, easy processing and other advantages. Compared with PA11, another long carbon chain nylon material, PA12's raw material butadiene is only one-third the price of PA11's raw material castor oil, and can be used in most scenarios instead of PA11, and has wide applications in many fields such as automotive fuel hoses, air brake hoses, submarine cables, and 3D printing. Among long-chain nylon, PA12 has great advantages compared with other nylon materials, its advantages are the lowest water absorption, lowest density, low melting point, impact resistance, friction resistance, low temperature resistance, fuel resistance, good dimensional stability, good anti-noise effect, etc. PA12 has the properties of PA6, PA66 and polyolefin (PE, PP) at the same time, to achieve the combination of lightweight and physical and chemical properties, with performance It has the advantages of light weight and physical and chemical properties. PA12-LCF If the base material is compared to concrete, the fiber is like steel reinforcement, and mixing the two is like adding steel reinforcement to concrete. If there is only concrete, the castings will easily crack under external forces, but once the high-strength reinforcement is added to it and the concrete wraps it sufficiently, they will become a single unit. When the object is subjected to external forces, the rebar can withstand most of the external forces, making the structural strength of this whole very high. Carbon fiber has many excellent properties, high axial strength and modulus of carbon fiber, low density, high specific performance, no creep, resistance to ultra-high temperature in non-oxidizing environment, good fatigue resistance, specific heat and electrical conductivity between non-metal and metal, small coefficient of thermal expansion and anisotropy, good corrosion resistance, good X-ray transmittance. Good electrical and thermal conductivity, good electromagnetic shielding, etc. Compared with traditional glass fiber, carbon fiber has more than 3 times of Young's modulus; it is about 2 times of Young's modulus compared with Kevlar fiber, which is insoluble and swollen in organic solvents, acids and alkalis, and has outstanding corrosion resistance. Nylon itself is an engineering plastic with excellent performance, but moisture absorption, poor dimensional stability of products. Strength and hardness is also far from metal. In order to overcome these shortcomings, as early as before the 70s. People have used carbon fiber or other varieties of fibers for reinforcement to improve its performance. Carbon fiber reinforced nylon materials have developed rapidly in recent years, because nylon and carbon fiber are excellent performance in the field of engineering plastics materials, its compound material synthesis reflects the superiority of the two, such as strength and rigidity than unreinforced nylon is much higher, high temperature creep is small, thermal stability has improved significantly, good dimensional accuracy, wear resistance. Excellent damping, compared with glass fiber reinforced has better performance. Therefore, carbon fiber reinforced nylon (CF/PA) composites have developed rapidly in recent years. Datasheet for reference Nylon 12 has low water absorption, good low temperature resistance, good air tightness, excellent alkali and grease resistance, medium resistance to alcohols and inorganic dilute acids and aromatics, good mechanical and electrical properties, and is a self-extinguishing material. Application Suitable for the automotive, sports parts, solar energy, high-end toys and other industries. Other products you may wonder PP-LCF PA6-LCF PA66-LCF ...

- Nylon composite pellets Polymer granules

- Nylon polymer LCF manufacturer

- Modified materials Nylon PA12

- extrusion level Nylon modified

- pa lcf30 producer mess production good price

- carbone fiber reinforced pa12 pellets

Tags :

-

Xiamen LFT Polyamide 12 Long Carbon Fiber Composite Nylon Pellets PolymerLFT PA12 Long Carbon Fiber Composite Data Sheet and Technical Guidance

- Long Carbon Fiber Composite high strength

- LFT PA12 Long Carbon Fiber for car parts

- Nylon 12 Pellets Polymer engineering plastic

- PA12 Granules thermoplastic resin instead metal

- Pa12 Pellets Polyamide lightweight

- PA12 Long Carbon Fiber Composite

Tags :

-

LFT-G Polyamide 12 filled long carbon fiber plastic higher performance original colorPolyamide 12 material Polyamide (PA), commonly known as nylon, is a diverse group of polymers that are used as engineering plastics to replace metals to meet downstream industrial requirements for lightweight, low-cost products. The materials of the polyamide series exhibit resistance to high temperatures and electrical resistance. Due to their crystalline structure, they also show excellent chemical resistance. They have very good mechanical and barrier properties. In addition, these materials are very flame retardant. Polyamides were the first truly commercial synthetic fibers. When reinforced with carbon fibers (staple or long), their stiffness can compete with that of metals, which is why polyamides are often considered in metal replacement projects. Polyamides are widely used in the automotive, transportation, electronics, electrical, and consumer goods markets. Main properties of PA12: Excellent chemical resistance Low temperature impact resistance Aging resistance High temperature resistance Even if they do not excel in temperature resistance (HDT, peak temperature...) they show stable performance over time even if they do not excel in terms of temperature resistance (HDT, peak temperature...) Their excellent durability allows them to be used in a wide range of conditions (temperature, pressure, chemical ......) PA12 is particularly suitable for situations where long-term stability is required. Application More application fields you can contact us for technical advice. Details Number Color Length Sample Package MOQ Port of Loading Delivery time PA12-NA-LCF Natural color/Customized 6-25mm Available 20kg/bag 20kg Xiamen Port 7-45 days after shipment Produce processing Tests Contact us for more materials

- pa12 lcf pallets black

- Long carbon fiber Reinforced Polyamide12 for electrial accessories

- automotive parts materials PA12

- Low warpage electronic appliance

- thermoplastic resin pa12 with fiber

- Nylon 12 composite pellets Polymer granules

Tags :

-

Xiamen LFT Polyamide12 Long Carbon Fiber composites lightweight high toughnessPA12 information Long carbon chain nylon is a nylon with amide group in the main chain repeating unit of nylon molecule, and the length of methylene group between two amide groups is more than 10. We call it as long carbon chain nylon, including nylon 11, nylon 12, etc.. PA12 is nylon 12, also known as poly(dodecalactam) and poly(laurolactam), which is a kind of long carbon chain nylon. The basic raw material for polymerization is butadiene, a semi-crystalline - crystalline thermoplastic material. Nylon 12 is the most widely used long carbon chain nylon, it has most of the general properties of nylon, in addition to low water absorption, and has high dimensional stability, high temperature resistance, corrosion resistance, good toughness, easy processing and other advantages. Compared with PA11, another long carbon chain nylon material, PA12's raw material butadiene is only one-third the price of PA11's raw material castor oil, and can be used in most scenarios instead of PA11, and has wide applications in many fields such as automotive fuel hoses, air brake hoses, submarine cables, and 3D printing. Among long-chain nylon, PA12 has great advantages compared with other nylon materials, its advantages are the lowest water absorption, lowest density, low melting point, impact resistance, friction resistance, low temperature resistance, fuel resistance, good dimensional stability, good anti-noise effect, etc. PA12 has the properties of PA6, PA66 and polyolefin (PE, PP) at the same time, to achieve the combination of lightweight and physical and chemical properties, with performance It has the advantages of light weight and physical and chemical properties. PA12-LCF If the base material is compared to concrete, the fiber is like steel reinforcement, and mixing the two is like adding steel reinforcement to concrete. If there is only concrete, the castings will easily crack under external forces, but once the high-strength reinforcement is added to it and the concrete wraps it sufficiently, they will become a single unit. When the object is subjected to external forces, the rebar can withstand most of the external forces, making the structural strength of this whole very high. Carbon fiber has many excellent properties, high axial strength and modulus of carbon fiber, low density, high specific performance, no creep, resistance to ultra-high temperature in non-oxidizing environment, good fatigue resistance, specific heat and electrical conductivity between non-metal and metal, small coefficient of thermal expansion and anisotropy, good corrosion resistance, good X-ray transmittance. Good electrical and thermal conductivity, good electromagnetic shielding, etc. Compared with traditional glass fiber, carbon fiber has more than 3 times of Young's modulus; it is about 2 times of Young's modulus compared with Kevlar fiber, which is insoluble and swollen in organic solvents, acids and alkalis, and has outstanding corrosion resistance. Nylon itself is an engineering plastic with excellent performance, but moisture absorption, poor dimensional stability of products. Strength and hardness is also far from metal. In order to overcome these shortcomings, as early as before the 70s. People have used carbon fiber or other varieties of fibers for reinforcement to improve its performance. Carbon fiber reinforced nylon materials have developed rapidly in recent years, because nylon and carbon fiber are excellent performance in the field of engineering plastics materials, its compound material synthesis reflects the superiority of the two, such as strength and rigidity than unreinforced nylon is much higher, high temperature creep is small, thermal stability has improved significantly, good dimensional accuracy, wear resistance. Excellent damping, compared with glass fiber reinforced has better performance. Therefore, carbon fiber reinforced nylon (CF/PA) composites have developed rapidly in recent years. Datasheet for reference Nylon 12 has low water absorption, good low temperature resistance, good air tightness, excellent alkali and grease resistance, medium resistance to alcohols and inorganic dilute acids and aromatics, good mechanical and electrical properties, and is a self-extinguishing material. Application Suitable for the automotive, sports parts, solar energy, high-end toys and other industries. Other products you may wonder PP-LCF PA6-LCF PA66-LCF ...view more

-

LFT-G Polyamide 12 long carbon fiber reinforced compounds nylon for car partsLong carbon fiber Carbon fiber has many excellent properties, high axial strength and modulus, low density, high specific performance, no creep, super high temperature resistance in non-oxidizing environment, good fatigue resistance, specific heat and electrical conductivity between non-metal and metal, small coefficient of thermal expansion and anisotropy, good corrosion resistance, good X-ray transmission. Good electrical and thermal conductivity, good electromagnetic shielding, etc. Compared with traditional glass fiber, carbon fiber has more than 3 times of Young's modulus; it is about 2 times of Young's modulus compared with Kevlar fiber, which is insoluble and swollen in organic solvents, acids and alkalis, and has outstanding corrosion resistance. But is there a way to reduce the price of carbon fiber? That is to mix it with relatively cheap nylon material to form a composite material with good performance and meet the requirements. In that case, there is no doubt that carbon fiber nylon will definitely have a place in the composite material. Nylon itself is an engineering plastic with excellent performance, but moisture absorption, poor dimensional stability of products. Strength and hardness are also far from metal. In order to overcome these shortcomings, as early as before the 70s. People have used carbon fiber or other varieties of fibers for reinforcement to improve its performance. Carbon fiber reinforced nylon materials have developed rapidly in recent years, because nylon and carbon fiber are excellent performance in the field of engineering plastics materials, its compound material synthesis reflects the superiority of the two, such as strength and rigidity than unreinforced nylon is much higher, high temperature creep is small, thermal stability has improved significantly, good dimensional accuracy, wear resistance. Excellent damping, compared with glass fiber reinforced has better performance. Therefore, carbon fiber reinforced nylon (CF / PA) composites have developed rapidly in recent years. And for 3D printing using SLS technology is the most suitable technical means to achieve carbon fiber reinforced nylon. TDS for reference Application Our company Xiamen LFT composite plastic Co., Ltd is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) & Long Carbon Fiber Series (LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm in length. The company's continuous infiltration reinforced thermoplastics have passed ISO9001&16949 system certification, and the products have obtained lots of national trademarks and patents.

- long fibre reinforced thermoplastics

- carbon fiber reinforced plastics granules

- long carbon fiber reinforced pa12

- long fiber composite pa6 granules

- pa6 lcf polymers carbon fiber CFRP good price polymer

Tags :

-

Xiamen LFT Polyamide 12 Long Carbon Fiber Composite Nylon Pellets PolymerLFT PA12 Long Carbon Fiber Composite Data Sheet and Technical Guidanceview more

-

Polyamide 12 filling long carbon fiber compounds high impact resistance for car partsLong Carbon Fiber Product Information body { font-family: Arial, sans-serif; color: #333333; line-height: 1.6; background-color: #ffffff; margin: 0; padding: 0 20px; } h2 { color: #339933; font-size: 28px; margin-top: 40px; margin-bottom: 20px; } h3 { color: #669900; font-size: 24px; margin-top: 30px; margin-bottom: 15px; } p { font-size: 18px; margin-bottom: 15px; } ul { font-size: 18px; margin-bottom: 15px; padding-left: 20px; } img { max-width: 100%; height: auto; margin: 20px 0; display: block; } table { width: 100%; border-collapse: collapse; margin-bottom: 20px; } table, th, td { border: 1px solid #000; } th, td { text-align: center; padding: 10px; font-size: 18px; } .section { margin-bottom: 40px; } Long Carbon Fiber Carbon fiber has many excellent properties: high axial strength and modulus, low density, high specific performance, no creep, super high temperature resistance in non-oxidizing environments, good fatigue resistance, thermal and electrical conductivity, small coefficient of thermal expansion and anisotropy, corrosion resistance, and good X-ray transmission. It also offers excellent electromagnetic shielding. Compared with traditional glass fiber, carbon fiber has over 3 times the Young's modulus, and about 2 times that of Kevlar fiber. Insoluble in organic solvents, acids, and alkalis, it exhibits outstanding corrosion resistance. To reduce costs, carbon fiber can be mixed with relatively inexpensive nylon to form composite materials with good performance. This ensures carbon fiber reinforced nylon will occupy a significant place in composite material applications. Nylon itself is an engineering plastic with excellent performance, but suffers from moisture absorption and poor dimensional stability. Early research, even before the 1970s, introduced carbon fiber or other fibers to reinforce nylon, improving its strength, hardness, heat resistance, dimensional accuracy, wear resistance, and damping performance. Compared with glass fiber reinforcement, carbon fiber reinforced nylon (CF/PA) performs better. For 3D printing, SLS technology is the most suitable method for producing CF/PA composites. TDS for Referenceview more

-

Xiamen LFT Polyamide12 with addition Long Carbon Fiber composite lightweight sample availablePA12 information Long carbon chain nylon is a nylon with amide group in the main chain repeating unit of nylon molecule, and the length of methylene group between two amide groups is more than 10. We call it as long carbon chain nylon, including nylon 11, nylon 12, etc.. PA12 is nylon 12, also known as poly(dodecalactam) and poly(laurolactam), which is a kind of long carbon chain nylon. The basic raw material for polymerization is butadiene, a semi-crystalline - crystalline thermoplastic material. Nylon 12 is the most widely used long carbon chain nylon, it has most of the general properties of nylon, in addition to low water absorption, and has high dimensional stability, high temperature resistance, corrosion resistance, good toughness, easy processing and other advantages. Compared with PA11, another long carbon chain nylon material, PA12's raw material butadiene is only one-third the price of PA11's raw material castor oil, and can be used in most scenarios instead of PA11, and has wide applications in many fields such as automotive fuel hoses, air brake hoses, submarine cables, and 3D printing. Among long-chain nylon, PA12 has great advantages compared with other nylon materials, its advantages are the lowest water absorption, lowest density, low melting point, impact resistance, friction resistance, low temperature resistance, fuel resistance, good dimensional stability, good anti-noise effect, etc. PA12 has the properties of PA6, PA66 and polyolefin (PE, PP) at the same time, to achieve the combination of lightweight and physical and chemical properties, with performance It has the advantages of light weight and physical and chemical properties. PA12-LCF If the base material is compared to concrete, the fiber is like steel reinforcement, and mixing the two is like adding steel reinforcement to concrete. If there is only concrete, the castings will easily crack under external forces, but once the high-strength reinforcement is added to it and the concrete wraps it sufficiently, they will become a single unit. When the object is subjected to external forces, the rebar can withstand most of the external forces, making the structural strength of this whole very high. Carbon fiber has many excellent properties, high axial strength and modulus of carbon fiber, low density, high specific performance, no creep, resistance to ultra-high temperature in non-oxidizing environment, good fatigue resistance, specific heat and electrical conductivity between non-metal and metal, small coefficient of thermal expansion and anisotropy, good corrosion resistance, good X-ray transmittance. Good electrical and thermal conductivity, good electromagnetic shielding, etc. Compared with traditional glass fiber, carbon fiber has more than 3 times of Young's modulus; it is about 2 times of Young's modulus compared with Kevlar fiber, which is insoluble and swollen in organic solvents, acids and alkalis, and has outstanding corrosion resistance. Nylon itself is an engineering plastic with excellent performance, but moisture absorption, poor dimensional stability of products. Strength and hardness is also far from metal. In order to overcome these shortcomings, as early as before the 70s. People have used carbon fiber or other varieties of fibers for reinforcement to improve its performance. Carbon fiber reinforced nylon materials have developed rapidly in recent years, because nylon and carbon fiber are excellent performance in the field of engineering plastics materials, its compound material synthesis reflects the superiority of the two, such as strength and rigidity than unreinforced nylon is much higher, high temperature creep is small, thermal stability has improved significantly, good dimensional accuracy, wear resistance. Excellent damping, compared with glass fiber reinforced has better performance. Therefore, carbon fiber reinforced nylon (CF/PA) composites have developed rapidly in recent years. Datasheet for reference Nylon 12 has low water absorption, good low temperature resistance, good air tightness, excellent alkali and grease resistance, medium resistance to alcohols and inorganic dilute acids and aromatics, good mechanical and electrical properties, and is a self-extinguishing material. Application Suitable for the automotive, sports parts, solar energy, high-end toys and other industries. Other products you may wonder PP-LCF PA6-LCF PA66-LCF ...view more

-

LFT-G Polyamide 12 long carbon fiber filled modified nylon12 high impact resistance and toughnessLong carbon fiber Carbon fiber has many excellent properties, high axial strength and modulus, low density, high specific performance, no creep, super high temperature resistance in non-oxidizing environment, good fatigue resistance, specific heat and electrical conductivity between non-metal and metal, small coefficient of thermal expansion and anisotropy, good corrosion resistance, good X-ray transmission. Good electrical and thermal conductivity, good electromagnetic shielding, etc. Compared with traditional glass fiber, carbon fiber has more than 3 times of Young's modulus; it is about 2 times of Young's modulus compared with Kevlar fiber, which is insoluble and swollen in organic solvents, acids and alkalis, and has outstanding corrosion resistance. But is there a way to reduce the price of carbon fiber? That is to mix it with relatively cheap nylon material to form a composite material with good performance and meet the requirements. In that case, there is no doubt that carbon fiber nylon will definitely have a place in the composite material. Nylon itself is an engineering plastic with excellent performance, but moisture absorption, poor dimensional stability of products. Strength and hardness are also far from metal. In order to overcome these shortcomings, as early as before the 70s. People have used carbon fiber or other varieties of fibers for reinforcement to improve its performance. Carbon fiber reinforced nylon materials have developed rapidly in recent years, because nylon and carbon fiber are excellent performance in the field of engineering plastics materials, its compound material synthesis reflects the superiority of the two, such as strength and rigidity than unreinforced nylon is much higher, high temperature creep is small, thermal stability has improved significantly, good dimensional accuracy, wear resistance. Excellent damping, compared with glass fiber reinforced has better performance. Therefore, carbon fiber reinforced nylon (CF / PA) composites have developed rapidly in recent years. And for 3D printing using SLS technology is the most suitable technical means to achieve carbon fiber reinforced nylon. TDS for reference Application Our company Xiamen LFT composite plastic Co., Ltd is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) & Long Carbon Fiber Series (LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm in length. The company's continuous infiltration reinforced thermoplastics have passed ISO9001&16949 system certification, and the products have obtained lots of national trademarks and patents.

- long fibre reinforced thermoplastics resin pa12

- thermoplastic Polyamide 12 natural color with addition fiber

- wear resistance injection molding pa12 gf

- pa12 lcf for car parts

Tags :

-

Lft-g PA12 raw material filled long carbon fiber new plastic higher performance original color sample freePolyamide 12 material Polyamide (PA), commonly known as nylon, is a diverse group of polymers that are used as engineering plastics to replace metals to meet downstream industrial requirements for lightweight, low-cost products. The materials of the polyamide series exhibit resistance to high temperatures and electrical resistance. Due to their crystalline structure, they also show excellent chemical resistance. They have very good mechanical and barrier properties. In addition, these materials are very flame retardant. Polyamides were the first truly commercial synthetic fibers. When reinforced with carbon fibers (staple or long), their stiffness can compete with that of metals, which is why polyamides are often considered in metal replacement projects. Polyamides are widely used in the automotive, transportation, electronics, electrical, and consumer goods markets. Main properties of PA12: Excellent chemical resistance Low temperature impact resistance Aging resistance High temperature resistance Even if they do not excel in temperature resistance (HDT, peak temperature...) they show stable performance over time even if they do not excel in terms of temperature resistance (HDT, peak temperature...) Their excellent durability allows them to be used in a wide range of conditions (temperature, pressure, chemical ......) PA12 is particularly suitable for situations where long-term stability is required. Application More application fields you can contact us for technical advice. Details Number Color Length Sample Package MOQ Port of Loading Delivery time PA12-NA-LCF Natural color/Customized 6-25mm Available 20kg/bag 20kg Xiamen Port 7-45 days after shipment Produce processing Tests Contact us for more materialsview more

-

LFT-G Nylon 12 with filler long carbon fiber LCF 20%-60% compounds high strength lightweight 6-25mmPolyamide 12 PA12, nylon 12, also known as polydodecalactam and polylactam, is a long carbon chain nylon. There are non-polar methylene groups in nylon 12, and the number is large, which makes the flexibility of nylon 12 molecular chain larger; the amide group in nylon 12 is polar, and the cohesion energy is large, and it can form hydrogen bonds between molecules, which makes the arrangement of molecules more regular. Therefore, the crystallinity of nylon 12 is high, and the strength is also higher. Nylon 12 (PA12) has low water absorption, good low temperature resistance, good air tightness, excellent alkali resistance, grease performance, medium resistance to alcohols and inorganic dilute acids and aromatics, good mechanical properties and electrical properties, and is a self-extinguishing material. 1) Density The relative density of nylon 12 is only 1.01-1.03, which is the smallest among all engineering plastics, which has a certain effect on reducing the mass of the car and lowering the fuel consumption. If compared by unit volume, nylon 12 has advantages in price and performance. 2) Melting point The melting point of nylon 12 is 172-178℃, which is slightly lower than that of nylon 11, and it can fully meet the working temperature requirement of automobile fuel and air brake pipes. 3)Water absorption As we all know, the biggest drawback of nylon products is the large water absorption, and it is difficult to ensure the dimensional stability. However, due to the increase of methylene molecules in nylon 12, the influence of hydrophilic groups is greatly reduced, therefore, nylon 12 has the lowest water absorption rate among nylon products, which reduces the change of performance and size of products caused by water absorption, which makes nylon 12 have great advantages. After water absorption, the tensile strength of nylon 12 decreases very little, while nylon 66 and nylon 6 have great changes. 4) Impact strength Impact strength is an important technical index, and it is especially important for nylon 12 tubes that are often exposed to air. Nylon 12 at -20 ℃ and -40 ℃ according to the standard test, no fracture phenomenon, fully meet the requirements of use. Nylon 12 impact resistance is very good. 5)Low temperature performance Nylon 12 has the lowest brittleness temperature of -70 degrees Celsius, so it can be widely used for parts with low temperature resistance. 6) Flexibility The effect of plasticizers on the physical properties of nylon 12 is concentrated on the elastic modulus of the resin. There are three basic types of nylon 12 resins, the main difference between them is the different plasticizer content and the formation of different flexibility. As the content of plasticizer extractable components increases, the elastic modulus of the resin decreases. 7)Low abrasion and low friction properties Nylon 12 has excellent low-wear and low-friction properties and self-lubricating properties, so the frictional noise of Nylon 12 products is very low. 8)Fuel resistance In the automobile, the current use of oxygenated fuel, high aromatic fuel and alcohol mixed fuel will lead to the decomposition of many hose materials. Only nylon 11, nylon 12 and fluorocarbon elastomers have been tested for use in this environment. Under the action of motor fuels, all nylons dissolve, resulting in dimensional changes, especially in methanol-containing gasoline, where nylons containing large amounts of amide groups such as nylon 6 dissolve much more than nylons containing small amounts of amide groups such as nylon 12 %. It is found that the fuel containing 15% methanol has a great effect on nylon. 9) Resistant to zinc chloride solution Zinc chloride will appear in the environment under the car. Under certain temperature and humidity, the salt on the road reacts with galvanized steel or zinc-containing primer to form a small amount of zinc chloride. Zinc chloride is highly corrosive, but Nylon 12 is highly resistant to zinc chloride solutions. Ozone aging, UV exposure, temperature conditions, etc., can bring varying degrees of damage to parts and reduce service life. Since nylon 12 does not contain the + 2 3 2 + unsaturated double bond, which is susceptible to ozone attack, it does not suffer from ozone aging. In addition, the high crystallinity of nylon 12 and its high melting temperature make it more stable in terms of heat resistance, and the addition of heat stabilizers increases its heat resistance exponentially. When exposed to sunlight, its energy can cause the chemical bonds of organic materials to break. The bonding energy of C-H, C-O and C-N bonds in nylon 12 is so large that UV light is not enough to break them, but only the C-C bonds with smaller bonding energy; therefore, after adding appropriate anti-aging agents to the raw materials, the UV resistance of nylon 12 is excellent. Polyamide 12 - Long carbon fiber In the modified engineering plastics industry, long fiber reinforced composites are composites made fr...

- polyamide 12 engineering plastics lcf

- reinforced nylon 12 cfrp black

- injection molding pa12 carbon fiber

- LFT-G new materials pa12 cf instead metal

- green plastic recycled pa12 lcf

Tags :

-

LFT-G PA12 Polyamide12 30% Long Carbon Fiber composite higher performance lightweight sample availablePA12 information Long carbon chain nylon is a nylon with amide group in the main chain repeating unit of nylon molecule, and the length of methylene group between two amide groups is more than 10. We call it as long carbon chain nylon, including nylon 11, nylon 12, etc.. PA12 is nylon 12, also known as poly(dodecalactam) and poly(laurolactam), which is a kind of long carbon chain nylon. The basic raw material for polymerization is butadiene, a semi-crystalline - crystalline thermoplastic material. Nylon 12 is the most widely used long carbon chain nylon, it has most of the general properties of nylon, in addition to low water absorption, and has high dimensional stability, high temperature resistance, corrosion resistance, good toughness, easy processing and other advantages. Compared with PA11, another long carbon chain nylon material, PA12's raw material butadiene is only one-third the price of PA11's raw material castor oil, and can be used in most scenarios instead of PA11, and has wide applications in many fields such as automotive fuel hoses, air brake hoses, submarine cables, and 3D printing. Among long-chain nylon, PA12 has great advantages compared with other nylon materials, its advantages are the lowest water absorption, lowest density, low melting point, impact resistance, friction resistance, low temperature resistance, fuel resistance, good dimensional stability, good anti-noise effect, etc. PA12 has the properties of PA6, PA66 and polyolefin (PE, PP) at the same time, to achieve the combination of lightweight and physical and chemical properties, with performance It has the advantages of light weight and physical and chemical properties. PA12-LCF If the base material is compared to concrete, the fiber is like steel reinforcement, and mixing the two is like adding steel reinforcement to concrete. If there is only concrete, the castings will easily crack under external forces, but once the high-strength reinforcement is added to it and the concrete wraps it sufficiently, they will become a single unit. When the object is subjected to external forces, the rebar can withstand most of the external forces, making the structural strength of this whole very high. Carbon fiber has many excellent properties, high axial strength and modulus of carbon fiber, low density, high specific performance, no creep, resistance to ultra-high temperature in non-oxidizing environment, good fatigue resistance, specific heat and electrical conductivity between non-metal and metal, small coefficient of thermal expansion and anisotropy, good corrosion resistance, good X-ray transmittance. Good electrical and thermal conductivity, good electromagnetic shielding, etc. Compared with traditional glass fiber, carbon fiber has more than 3 times of Young's modulus; it is about 2 times of Young's modulus compared with Kevlar fiber, which is insoluble and swollen in organic solvents, acids and alkalis, and has outstanding corrosion resistance. Nylon itself is an engineering plastic with excellent performance, but moisture absorption, poor dimensional stability of products. Strength and hardness is also far from metal. In order to overcome these shortcomings, as early as before the 70s. People have used carbon fiber or other varieties of fibers for reinforcement to improve its performance. Carbon fiber reinforced nylon materials have developed rapidly in recent years, because nylon and carbon fiber are excellent performance in the field of engineering plastics materials, its compound material synthesis reflects the superiority of the two, such as strength and rigidity than unreinforced nylon is much higher, high temperature creep is small, thermal stability has improved significantly, good dimensional accuracy, wear resistance. Excellent damping, compared with glass fiber reinforced has better performance. Therefore, carbon fiber reinforced nylon (CF/PA) composites have developed rapidly in recent years. Datasheet for reference Nylon 12 has low water absorption, good low temperature resistance, good air tightness, excellent alkali and grease resistance, medium resistance to alcohols and inorganic dilute acids and aromatics, good mechanical and electrical properties, and is a self-extinguishing material. Application Suitable for the automotive, sports parts, solar energy, high-end toys and other industries. Other products you may wonder PP-LCF PA6-LCF PA66-LCF ...

- Nylon polymer LCF

- pa lcf30

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文