-

PA12 NA LCF black color high temperature resistance for automotive partsLong carbon chain nylon is nylon with an amide group in the main chain repeating unit of nylon molecule, and the length of methylene between the two amide groups is greater than 10. We call it long carbon chain nylon, including nylon 11, nylon 12, etc. PA12 is nylon 12, also known as polydodecactam, polylauractam, is a long carbon chain nylon. The basic material for its polymerization is butadiene, a semi-crystalline - crystalline thermoplastic material. Nylon 12 is the most widely used long carbon chain nylon, in addition to most of the general properties of nylon, low water absorption, and has high dimensional stability, high temperature resistance, corrosion resistance, good toughness, easy processing and other advantages. Compared with PA11, another long carbon chain nylon material, the price of butadiene, the raw material of PA12, is only one third of the price of castor oil, the raw material of PA11. It can replace PA11 and be applied in most scenes, and has a wide range of applications in automobile fuel pipe, air brake hose, submarine cable, 3D printing and many other fields. In long chain nylon, compared with other nylon materials, PA12 has great advantages, such as the lowest water absorption rate, the lowest density, low melting point, impact resistance, friction resistance, low temperature resistance, fuel resistance, good dimensional stability, good anti-noise effect. PA12 has the properties of PA6, PA66 and polyolefin (PE, PP) at the same time, achieving the combination of lightweight and physical and chemical properties, and has advantages in performance. There are a large number of non-polar methylene groups in nylon 12, which makes nylon 12 molecular chain more compliant. The amide group in nylon 12 is polar, and the cohesion energy is very large, it can form hydrogen bonds between the molecules, so that the molecular arrangement is regular. Therefore, nylon 12 has high crystallinity and high strength. Nylon 12 has low water absorption, good low temperature resistance, good air tightness, excellent alkali and oil resistance, medium resistance to alcohol, inorganic dilute acid and aromatic hydrocarbons, good mechanical and electrical properties, and is a self-flameout material. 1) Density The relative density of nylon 12 is only 1.01-1.03, which is the smallest among all engineering plastics, which has a certain effect on reducing the quality of vehicles and reducing fuel consumption. When compared by unit volume, nylon 12 has advantages in price and performance. 2) Melting point The melting point of nylon 12 is 172-178℃, slightly lower than nylon 11, can fully meet the requirements of automobile fuel pipe and brake pipe working environment temperature. 3) Water absorption As we all know, the biggest disadvantage of nylon products is large water absorption, dimensional stability is difficult to ensure. And PA12 has the lowest water absorption rate of nylon products, this is due to the methylene molecules in nylon 12 greatly reduce the hydrophilic groups, which makes nylon 12 has a great advantage. 4) Impact strength Impact strength is an important technical index, especially for nylon 12 pipe often exposed to air. Nylon 12 under -20℃ and -40℃ according to the standard test, no fracture phenomenon, fully meet the requirements of use. Nylon 12 has excellent impact resistance. 5) Low temperature performance Nylon 12 has the lowest brittleness temperature of -70 degrees Celsius, so it can be widely used in low-temperature resistant parts. 6) Flexibility The influence of plasticizer on the physical properties of nylon 12 is concentrated on the elastic modulus of resin. Nylon 12 has three basic types of resin, their main difference is due to the plasticizer content of different forms of flexibility. The elastic modulus of resin decreases with the increase of extractable component content of plasticizer. 7) Low wear and low friction performance Nylon 12 has excellent low abrasion and low friction properties and self lubricating properties, so the friction noise of nylon 12 products is very low. 8) Fuel resistance In automobiles, the mixture of oxygenated fuel, high aromatic fuel and alcohol currently used can cause the breakdown of many hose materials. After the test, only nylon 11, nylon 12 and fluorocarbon resin elastomers can be used in this environment. Almost other types of nylon melt under the action of automobile fuel, resulting in a change in size. 9) Resistance to zinc chloride solution Zinc chloride is found under the car. Under certain temperature and humidity, the salt on the road reacts with galvanized steel plate or zinc-containing primer to form the corrosive zinc chloride. In addition, ozone aging, ultraviolet radiation, temperature conditions and so on, will bring different degrees of damage to the parts, reduce the service life. Nylon 12 is very resistant to zinc chloride solution. Because there is no unsaturated double bond in nylon 12 which is susceptible to ozone attack, ozone ...view more

-

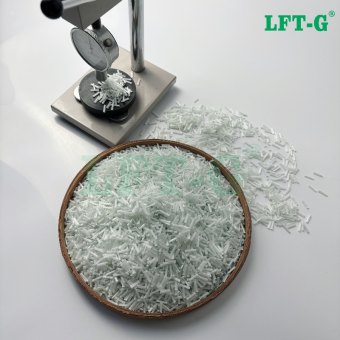

LFT-D PA6 Long Carbon Fiber modified plastic high toughness strength 12mm sample availableWhat is PA6? Nylon6 (PA6), also known as polyamide 6, English name: Polyamide6 or Nylon6, PA6 for short; That is, polycaprolactam, obtained from caprolactam ring-opening polycondensation. It is translucent or opaque opalescent resin, with superior mechanical properties, stiffness, toughness, wear resistance and mechanical shock absorption, good insulation and chemical resistance. Widely used in automotive parts, electronic and electrical parts and other fields. What are the advantages and disadvantages of PA6? Main advantages of PA: 1. High mechanical strength, good toughness, high tensile and compressive strength. 2. outstanding fatigue resistance, parts after repeated bending can still maintain the original mechanical strength. 3. high softening point, heat resistant. 4. smooth surface, small friction coefficient, wear-resistant. 5. corrosion resistance, very alkali and most salts, also resistant to weak acid, oil, gasoline, aromatic compounds and general solvents, aromatic compounds are inert, but not resistant to strong acids and oxidants. 6. with self-extinguishing, non-toxic, odorless, good weather resistance. 7. Excellent electrical performance. Good electrical insulation, nylon volume resistance is high, high breakdown voltage resistance, in dry environment, can be used as power frequency insulation material, even in high humidity environment still has good electrical insulation. 8. light weight, easy to dye, easy to form. Main disadvantages of PA: 1. easy to absorb water. High water absorption, saturated water can reach more than 3%. The dimensional stability and electrical properties are affected to some extent, especially the thickening of thin-walled parts. Water absorption also greatly reduces the mechanical strength of plastics. 2. Poor light resistance. In a long-term high temperature environment, it will oxidize with oxygen in the air, turn brown at the beginning, and then break and crack. 3. injection molding technology requirements are more strict: the existence of trace moisture will cause great damage to the quality of molding; The dimensional stability of the product is difficult to control because of thermal expansion. The existence of sharp Angle in the product will lead to stress concentration and reduce the mechanical strength; If the wall thickness is not uniform, it will lead to the distortion and deformation of the parts. High precision of equipment is required in post-processing. 4. will absorb water, alcohol and swelling, not resistant to strong acid and oxidant, can not be used as acid-resistant materials. There are many advantages of PA6, but also many disadvantages, these disadvantages limit the play of the advantages, so people thought of modifying methods to enhance its application. What is the Long Carbon Fiber reinforced PA6? Long carbon fiber reinforced composites offer significant weight savings and provide optimum strength and stiffness properties in reinforced thermoplastics. The excellent mechanical properties of long carbon fiber reinforced composites make it an ideal replacement for metals. Combined with the design and manufacturing advantages of injection molded thermoplastics, long carbon fiber composites simplify the re-imagining of components and equipment with demanding performance requirements. Its widespread use in aerospace and other advanced industries make it a "high-tech" perception of consumers - you can use it to market products and create differentiation from competitors. What is the differences between Long Carbon Fiber and Short Carbon Fiber? Compared with the short fiber, it has more excellent performance in mechanical properties. It is more suitable for large products and structural parts. It has 1-3 times higher (toughness) than short fiber, and the tensile strength (strength and rigidity) is increased by 0.5-1 times. TDS for reference only Application cases Product details Number Color Length MOQ Sample Package Port of Loading Delivery time PA6-NA-LCF50 Original color or as required About 12mm 20kg Available 20kg/bag Xiamen Port 7-15days after shipment Frequently asked questions 1. The product is easy to brittle, so changing to use long fiber reinforced thermoplastic materials can solve this problem? A: The overall mechanical properties must be improved. The characteristics of long glass fiber and long carbon fiber are the advantages in mechanical properties. It has 1-3 times higher (toughness) than short fiber, and the tensile strength(strength and rigidity) is increased by 0.5-1 times. 2. Are there any special progress requiremets of long carbon fiber injection molding products? A: We must consider the requirements of long carbon fiber for the injection molding machine screw nozzle, mold structure and injection molding process. Long carbon fiber is a relatively high cost material, and need to evaluate the cost performance problem in the selection process. 3. The cost of long fiber products is higher. Does it has a high recycling value? A: The...

- Polyamide6 reinforced material

- LFT-G brand carbon fiber series

- pa6 composite lcf

- Nylon6 pa compound

- Long carbon fiber filled plastic

- lcf50 fiber

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文