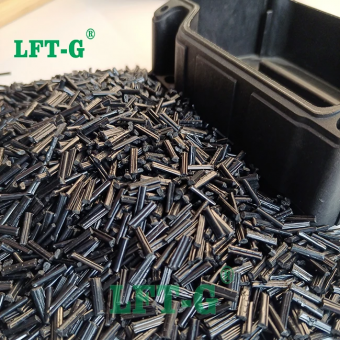

Polyetheretherketone PEEK with Long carbon fiber Reinforced repared by solution impregnation process.Polyetheretherketone PEEK with Long carbon fiber Reinforced is a special engineering plastic with excellent performance.

-

Reinforcing PEEK with Long Carbon Fibers High Strength CompoundsOur PEEK (Polyether Ether Ketone) long carbon fiber composite material is an advanced high-performance thermoplastic engineered for applications requiring exceptional mechanical properties, chemical resistance, and thermal stability. By reinforcing PEEK with long carbon fibers, this composite achieves outstanding strength, stiffness, and durability, making it an ideal choice for demanding industrial applications.

- Plastic PEEK with filler

- carbon fibre material properties

- carbon reinforced composites

- thermoplastic cfrp

- china carbon fiber plastic

- plastic compounds

Tags :

-

Advanced Carbon Materials Polyetheretherketone Resin Long Carbon Fiber Reinforced PelletsPEEK long carbon fiber reinforced material provides exceptional thermal stability, outstanding chemical resistance, and superior mechanical properties, making it ideal for the most demanding engineering applications. With its high strength, rigidity, and low friction characteristics, this material is widely used in aerospace, automotive, and industrial sectors. Its ability to withstand extreme temperatures and harsh chemical environments ensures reliable performance and durability in critical applications.

- peek automotive industry

- uses of peek in automotive industry

- peek composite

- peek pellets

- carbon fiber reinforced peek market

- peek-cf

Tags :

-

LFT Long Fiber Reinforced PEEK High Mechanical Properties PlasticLFT long carbon fiber reinforced PEEK material offers unmatched strength, stiffness, and exceptional resistance to high temperatures and chemicals. Its superior durability and dimensional stability make it ideal for demanding aerospace, automotive, and industrial applications, where performance and reliability are crucial.

- Polyether Ether Ketone CFRP resin Composites

- China factory Polyether Ether Ketone

- long carbon fiber filled PEEK materials

- OEM ODM Manufacturer PEEK plastic

- Plastic raw matetials injection mold PEEK

- PEEK polymer black color engineering plastic

Tags :

-

China Manufacturer PEEK Resin Long Carbon Fiber Reinforced PelletsPure PEEK itself is a special engineering plastic, with radiation resistance, self-lubrication, high temperature resistance, wear resistance, fatigue resistance and other characteristics. The performance of carbon fiber reinforced PEEK material has improved in many aspects compared with pure PEEK material. PEEK Long Carbon Fiber Reinforced Composite material is 5 times stronger than metal, 60% lighter and more than 10% better than similar products.

- PEEK materials supplier

- thermoplastic polymer plastic PEEK

- Factory sell Polyether ether ketone

- PEEK Carbon filled pellets

- Injection molding peek black color

- High strength PEEK properties

Tags :

-

UltraStrong Carbon Fiber Reinforced PEEK Composite – High-Performance Engineering MaterialPEEK carbon fiber reinforced composite materials combine the high-performance properties of PEEK with the strength and durability of carbon fiber, making them ideal for applications in extreme environments and 3D printing.

- High Temperature Plastic

- PEEK Composite Materials

- Carbon Fiber Reinforced PEEK

- High Performance Plastics

- 3D Printing PEEK

- PEEK Material Applications

Tags :

-

UltraStrong Carbon Fiber Reinforced PEEK Composite – High-Performance Engineering MaterialPEEK carbon fiber reinforced composite materials combine the high-performance properties of PEEK with the strength and durability of carbon fiber, making them ideal for applications in extreme environments and 3D printing.view more

-

Xiamen LFT Polyetheretherketone CF composite 20%-60% high performance natural colorProduct grade: General grade Fiber specification: 20%-60% Product feature: Flame resistant, Heat resistant, Chemical resistant, Low friction coefficient, Good load bearing Product application: Aviation, Machinery, Electronics, Chemicals, Automotive, Other high-tech fields.

- Good load bearing polyetheretherketone

- Low friction coefficient made bu own factory

- Own factory made pure and virgin peek

- Wide useage peek industrial materials reinforced peek

- Customized materials peek toughness Carbon

- Long Glass Fiber can be recycled peek aerospace

Tags :

-

LFT High Properties Polyetheretherketone Long Carbon Fiber Reinforced Thermoplastic CompoundsThe mechanical properties of PEEK allow it to be used as reinforcement material in various scenarios.

- carbon fiber reinforced peek mechanical properties

- peek 30 carbon fiber-reinforced

- peek carbon fiber composite

- peek material advantages and disadvantages

- peek material aerospace

- polyetheretherketone (peek) for medical applications

Tags :

-

Xiamen LFT-G Long Carbon Fiber Reinforced PEEK Composite Injection ModingPEEK filling long carbon fiber reinforced thermoplastic for lightweight car parts.

- Carbon fiber PEEK granules aerospace automotive parts

- Carbon fiber composite peek granules

- Plastic peek carbon fiber polymers peek resin

- Black color peek carbon fiber granules

- Black color peek carbon fiber plastic

- Peek carbon fiber reinforced pellet

Tags :

-

LFT-G PEEK Polyether ether ketone composite long carbon fiber thermoplastic resinPEEK-LCF Polyether ether ketone (abbreviated PEEK) not only has excellent mechanical, heat and chemical resistance properties, and low friction coefficient, good bearing meshing, is another kind of good self-lubricating material after polytetrafluoroethylene (PTFE), in the bearing capacity and wear resistance than PTFE performance is better, In no lubrication, low speed and high load, high temperature, humidity, pollution, corrosion and other harsh environment is especially suitable. On this basis, the addition of carbon fiber not only enhances its mechanical properties, its friction performance has important influence. At room temperature, the tensile strength of 30% carbon fiber reinforced PEEK composite doubled, and reached three times at 150℃. At the same time, the impact strength, bending strength and modulus of the reinforced composite were also greatly improved, the elongation was sharply reduced, and the thermal deformation temperature could exceed 300℃. The impact energy absorption rate of the composite directly affects the impact performance of the composite. The carbon fiber reinforced PEEK composite shows a specific energy absorption capacity of up to 180kJ/kg. The reinforced effect of carbon fiber can also resist the thermal softening of PEEK and form a transfer film with very high strength to a certain extent, which can effectively protect the contact area. Therefore, the friction coefficient and specific wear rate of carbon fiber reinforced PEEK composite are significantly lower than that of pure PEEK. Under the same experimental conditions, the friction and wear resistance of carbon fiber reinforced PEEK composites is obviously better than that of glass fiber PEEK composites, and the improvement effect of carbon fiber on the wear resistance of materials is more than 5 times that of glass fiber with the same dosage. Carbon fiber reinforced PEEK composite material is used in parts manufacturing, which can effectively avoid the surface cracks of metal or ceramic materials, and its excellent tribological properties even exceed that of ultra-high molar mass polyethylene. TDS Application Long carbon fiber reinforced PEEK is mainly applied in the following four areas: 1. Electronic and electrical appliances PEEK can maintain good electrical insulation in the harsh environment such as high temperature, high pressure and high humidity, and has the characteristics of non-deformation in a wide temperature range, so it is used as an ideal electrical insulation material in the field of electronic and electrical appliances. The mechanical properties, chemical corrosion resistance, radiation resistance and high temperature resistance of polyether ether ketone reinforced by carbon fiber have been further improved, and its application fields have been further expanded. 2. Aerospace Polyether ether ketone PEEK has the advantages of low density and good workability, so it is easy to be directly processed into high-demand parts, and carbon fiber reinforced polyether ether ketone composite material further enhances the overall performance of polyether ether ketone, so it is increasingly used in aircraft manufacturing. The fairing on Boeing's 757-200 series aircraft, for example, is made from carbon-fiber reinforced PEEK. In addition, Gereedschappen Fabrick of Amsterdam, the Netherlands, used a 30% carbon fiber reinforced PEEK composite to build a larger component and demonstrated that its mechanical properties could be used in aircraft balancing devices. 3. Automotive Automobile energy consumption is closely related to vehicle weight. Automobile lightweight can not only reduce fuel consumption and exhaust emissions, but also improve power performance and safety, which is an effective way to save energy. In addition to the lightweight design of the structure, the use of lightweight materials is a more direct method. With its advantages of low density, good performance and convenient technology, carbon fiber reinforced polyether ether ketone composites are more and more frequently used in the automobile industry, and show great potential of replacing steel with plastic. For example, Robert Bosch GmbH uses carbon fiber reinforced PEEK instead of metal as a feature of ABS. The lighter composite part reduces moment of inertia, which minimizes reaction times, greatly enhances the overall system's reactivity, and reduces costs compared to previously used metal parts. 4. Healthcare Currently available medical polymer materials are polytetrafluoroethylene, polylactic acid, silicone rubber and dozens of kinds, but from the point of view of biomedicine, these materials are not ideal, in the use of some side effects, and PEEK resin because of its non-toxic, light weight, abrasion resistance and other advantages, is the material closest to the human skeleton, can be organically combined with the body, Therefore, polyether ether ketone resin and its composite materials have been deeply studied and applied in spine and joint...

- PEEK long carbon fiber

- peek composite plastic modified

- peek resin modified direct sell

- peek lcf lft aircraft use aerospace fields

- long carbon fiber peek high demanding

- injection molding peek good price

Tags :

-

LFT-G Polyetheretherketone filling Long Carbon Fiber Polymers extra high strengthPEEK-Long carbon fiber Polyetheretherketone (PEEK), the complete English name for polyetheretherketone, is a specialty engineering plastic with excellent performance, and has more advantages than other specialty engineering plastics, such as wear resistance, high temperature resistance, high strength and high modulus, flame retardant and radiation resistant, and so on. In addition polyetheretherketone (PEEK) has good thermal stability and melt flow above the melting point, so polyetheretherketone (PEEK) also has the typical processing properties of thermoplastics. PEEK resin is nontoxic, lightweight, corrosion-resistant, and one of the closest materials to the human skeleton, which is well compatible with the musculature, so it is often used instead of metal to make human bones. Carbon fiber-reinforced PEEK composites make up for the weaknesses of toughness and deviations in impact strength. Carbon fiber-reinforced PEEK composites can exhibit high mechanical strength and hydrolytic stability under conditions such as hot water, steam, solvents, and chemical reagents, and can be used to prepare various medical devices that require high-temperature steam sterilization. Advantages of PEEK-LCF PEEK has high rigidity, good dimensional stability, low coefficient of linear expansion, and can withstand great stress without significant elongation over time, and its low density and good processing properties make it suitable for parts with high requirements for fineness. Among these elements, carbon fiber materials overlap highly with the characteristics of PEEK. Carbon fiber is not only one of the typical lightweight materials, it is also outstanding in terms of mechanical properties. As a result, carbon fiber reinforced PEEK composites can reduce weight by at least 70% compared to traditional metal materials. PEEK material itself is very wear-resistant, and good interface bonding with carbon fibers to further enhance its wear resistance, through the carbon fiber reinforced PEEK composite parts and cobalt alloy materials for wear comparison experiments, the results show that: at 23 ℃, using the M-200 wear machine at 400 rpm after 100 minutes of wear, found that the carbon fiber reinforced PEEK composite surface smooth The wear marks were small, and the carbon fiber bonded well with PEEK without fiber extraction. In contrast, the cobalt alloy surface wear marks are very obvious, even a large number of wear particles appear, the metal internal impurities image visible. PEEK exhibits high mechanical strength and hydrolytic stability in hot water, steam, solvents and chemical reagents, etc. Datasheet for reference PEEK-LCF application Q&A 1. What are the types of thermoplastic carbon fiber composites? Carbon fiber thermoplastic composites are composites with carbon fiber as the reinforcing material and thermoplastic resin as the matrix. From the reinforcement method of carbon fiber, it can be divided into long-cut carbon fiber (LCF) reinforced thermoplastic composites, short-cut carbon fiber (SCF) reinforced thermoplastic composites and continuous carbon fiber (CCF) reinforced thermoplastic composites. Long-cut carbon fiber and short-cut carbon fiber mainly refer to the application length of carbon fiber materials, there is no strict fixed distinction between the two, generally between a few millimeters to a few centimeters, the more common specifications are 6mm, 12mm, 20mm, 30mm, 50mm. Carbon fiber thermoplastic composites can also be classified according to the thermoplastic resin. There are many common thermoplastic resins, such as PE, PP, PVC, etc. However, thermoplastic resin composites with carbon fiber reinforcement are mostly used in aerospace, precision equipment and other demanding working environments, therefore, carbon fiber thermoplastic composites are more often made of polyether ether ketone (PEEK), PPS, polyimide ( PI), polyetherimide (PAI) and other mid- to high-end thermoplastic resins as the matrix to achieve the optimization of material performance. 2. How does thermoplastic carbon fiber composite material achieve low cost and environmental protection? Thermoplastic carbon fiber composites are used to make parts for high-end machinery. They have excellent machinability, vacuum forming, stamping mold plasticity, and bending processability. For example, Teijin has been able to add a recycling process to the process according to specific needs, and to shred and mold the corners of thermoplastic carbon fiber composite materials after stamping to make recycled materials for making small products or for molding nuts and studs on carbon fiber prototypes. This method can greatly reduce the loss of raw materials, improve the efficiency of the use of thermoplastic carbon fiber composite materials, reduce the overall cost, and thus achieve the purpose of environmental protection. In addition, thermoplastic carbon fiber composites can reduce the molding cycle time compared with thermoset carbon fiber composi...

- PEEK with long carbon fiber compounds

- Modified Plastic pellets peek engineering plastic

- factory in Xiamen thermoplastics

- peek cf30 injection molded 3D print

- PEEK pellets lcf 30 polymer resin carbon fibre

- self owing peek pellets reinforcement

Tags :

-

Xiamen LFT-G PEEK high quality modified thermoplastic fill long carbon fiber for automotivesWhat is PEEK? Polyether ether ketone (PEEK) is a semi-crystalline thermoplastic polymer material with rigid benzene ring, compliant ether bond and carbonyl group which can promote the intermolecular force in its molecular chain. PEEK has excellent wear resistance, electrical insulation, anti-radioactivity, chemical stability, biocompatibility and thermal stability. In addition, PEEK is reusable and has a high recovery rate. PEEK is widely used in aerospace, electronic and electrical appliances, biomedicine, Marine protection, automobile industry and other fields. PEEK material is an inert material with low surface free energy, and its mechanical properties and frictional properties cannot meet the needs of some special fields. Therefore, it is necessary to modify PEEK composite material to improve its comprehensive properties. At present, filling modification and blending modification are the main methods for preparing PEEK composite materials. Filler modified reinforcement materials mainly include fiber, inorganic particles and whisker; The polymer used for blending modification should have similar polarity and solubility to PEEK. The interface modification method can improve the interface adhesion and enhance the comprehensive properties of PEEK composites. What is PEEK filling Long Carbon Fiber? As a filling system, fiber can effectively carry part of the load, and the synergistic action between fiber and PEEK can improve the comprehensive performance of composite materials. Carbon fiber and glass fiber are widely used as filler modified composites because of their high strength, high modulus and high durability. Long carbon fiber (LCF) can be used as heterogeneous nucleating agent to promote the crystallization of PEEK in composite materials, which can effectively improve the mechanical and tribological properties of composite materials. PEEK/CF composites of different lengths were prepared by injection molding, and their infiltrating and tribological properties were studied. The results show that the addition of CF increases the contact Angle and decreases the hydrophilicity of the composites. But the friction coefficient of composites is reduced and the friction resistance is improved. Long carbon fiber (LCF) has better effect on reducing friction coefficient than short carbon fiber (SCF). TDS of PEEK for reference Application of PEEK CF Q&A 1. What are the advantages of long carbon fiber materials? A: Thermoplastic LFT Long carbon fiber material has high rigidity, good impact strength, low warpage, low shrinkage, electrical conductivity and electrostatic propertiea, and its mechanical properties are better than glass fiber series. Long carbon fiber has the characteristics of lighter and more convenient processing to replace metal products. 2. Are there any special process requirements of long carbon fiber injection molding products? A: We must consider the requirements of long carbon fiber for the injection molding machine screw nozzle, mold structure and injection molding process. Long carbon fiber is a relatively high cost material, and need to evaluate the cost performance problem in the selection process. 3. The cost of long fiber products is higher. Does it has a high recycling value? A: The thermoplastic LFT long fiber material can be recycled and reused very well. We will offer you: 1. LFT & LFRT material technical parameters and leading edge design 2. Mold front design and recommendations 3. Provide technical support such as injection molding and extrusion molding

- PEEK resin lcf low cost savings

- Polyether ether ketone filled lcf

- instead medal plastic peek long life

- injection molding platic peek catbon fiber

- long carbon fiber series peek filament

- higher toughness peek lcf for car aerospace

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文