PEEK carbon fiber reinforced composite materials combine the high-performance properties of PEEK with the strength and durability of carbon fiber, making them ideal for applications in extreme environments and 3D printing.

PEEK carbon fiber reinforced composite materials combine the high-performance properties of PEEK with the strength and durability of carbon fiber, making them ideal for applications in extreme environments and 3D printing.

item no.:

PEEK-NA-LCFPayment:

Discussedproduct origin:

ChinaColor:

Natural color or Customizedshipping port:

XiamenLead Time:

2-10 working days

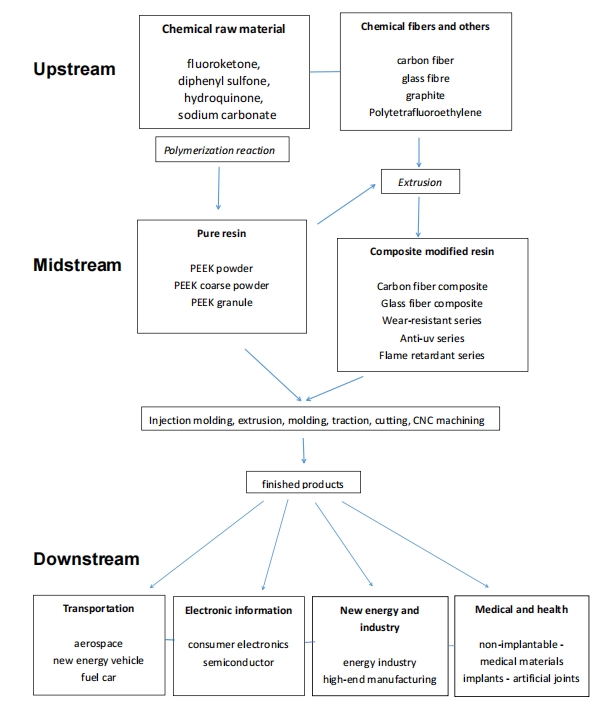

Pure PEEK itself is a special engineering plastic, with radiation resistance, self-lubrication, high temperature resistance, wear resistance, fatigue resistance and other characteristics. The performance of carbon fiber reinforced PEEK material has improved in many aspects compared with pure PEEK material.

After Filling Carbon Fiber

At room temperature, the tensile strength of carbon fiber modified PEEK material is doubled compared with that of non-enhanced, and it is tripled at 150℃. At the same time, the enhanced composite material has also been greatly improved in terms of impact strength, bending strength and modulus, and the elongation has been sharply reduced, and the thermal deformation temperature can exceed 300℃.

The impact energy absorption rate of the composite directly affects the performance of the composite under impact, and the carbon fiber reinforced peek composite shows a specific energy absorption capacity of up to 180kJ/kg.

Carbon fiber modified peek material has been widely used in aerospace, automobile manufacturing, electronics and electrical, medical and food processing fields.

PEEK can still maintain good electrical insulation in harsh environments such as high temperature, high pressure and high humidity, and has characteristics such as not easy to deform in a wide temperature range, so it is used as an ideal electrical insulation material in the field of electronic and electrical appliances.

Advantages of Polyether Ether Ketone (PEEK)

PEEK is fatigue and stress-resistant.

PEEK is resistant to high-pressure water and steam.

PEEK has high chemical resistance.

PEEK can be subjected to sterilization (like in autoclaving).

PEEK is easy to manufacture.

PEEK has very low emissions when exposed to flame.

About Xiamen LFT

Xiamen LFT has capabilities to provide assistance to you throughout an entire product launch

through product discussion, performance analysis, composite selection, composite pellet production, after-sales tracking.

In addition, we provide guidance on injection molding techniques