1. Material Composition

-

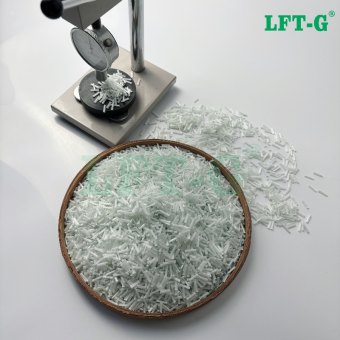

PEEK (Polyether Ether Ketone): PEEK is a semi-crystalline, high-performance thermoplastic known for its excellent mechanical strength, high-temperature resistance, chemical resistance, and wear properties. It remains stable in high-temperature and extreme environments.

-

Long Carbon Fiber: Carbon fiber is a lightweight, high-strength material with excellent heat resistance and tensile strength. Compared to short fibers, long carbon fibers provide more effective reinforcement, resulting in better structural support and enhanced material properties.

2. Key Properties

-

High Strength and Stiffness: Long carbon fiber-reinforced PEEK materials offer superior tensile and flexural strength, allowing them to withstand high loads without deformation or breaking, making them ideal for high-stress environments.

-

High-Temperature Resistance: PEEK has a glass transition temperature of around 143°C and a melting point of about 343°C, allowing the material to remain stable even at temperatures above 250°C.

-

Chemical Resistance: PEEK provides excellent resistance to acids, bases, solvents, and other chemicals. The addition of long carbon fibers further enhances this property, making the material suitable for harsh chemical environments.

-

Wear Resistance and Low Friction: Long carbon fibers improve the wear resistance of PEEK, extending its lifespan in friction-related applications. The material also exhibits a low coefficient of friction, reducing wear and tear.

-

Lightweight: Compared to metal materials, long carbon fiber-reinforced PEEK is much lighter, making it especially valuable in industries like aerospace, where weight reduction is critical.

-

Dimensional Stability: Long carbon fiber reinforcement ensures the composite remains dimensionally stable under high temperature and pressure, minimizing thermal expansion and contraction.

3. Applications

-

Aerospace: The lightweight and high-performance properties of long carbon fiber reinforced PEEK make it ideal for manufacturing aircraft components, rocket casings, and propellers, effectively replacing traditional metal materials to improve fuel efficiency.

-

Automotive: In the automotive industry, this material is used to produce high-stress components like engine parts, gears, and bearings. It not only reduces the weight of vehicles but also improves the durability and lifespan of parts.

-

Medical Devices: Thanks to PEEK’s biocompatibility and chemical resistance, long carbon fiber reinforced PEEK is used in medical implants, surgical instruments, and particularly in orthopedic implants, such as spinal cages and hip prosthetics.

-

Industrial Equipment: In industries like oil, gas, and chemicals, this composite material is used to manufacture seals, pumps, and valves that need to withstand high temperatures and corrosive chemicals.

4. Processing Methods

Long carbon fiber-reinforced PEEK materials are typically processed using thermoplastic molding techniques such as injection molding, extrusion, and compression molding. Due to PEEK's high melting point, processing requires higher temperatures and pressures. It is also essential to ensure that the carbon fibers are evenly distributed to achieve consistent material properties.

5. Advantages and Challenges

-

Advantages:

-

High strength and rigidity

-

Excellent high-temperature and chemical resistance

-

Superior wear and fatigue resistance

-

Lightweight, ideal for metal replacement

-

Biocompatible, suitable for medical applications

-

Challenges:

-

High cost: PEEK and carbon fiber are both expensive materials, which increases the production cost and limits widespread use in some industries.

-

Processing difficulty: Due to the high melting point and specific processing requirements, manufacturing long carbon fiber-reinforced PEEK requires specialized equipment and expertise.

6. Future Development Trends

As demand for lightweight, high-performance materials grows, the future for long carbon fiber-reinforced PEEK is promising. Potential developments include:

-

Cost optimization: New production technologies could help reduce manufacturing costs, allowing the material to be used in a broader range of applications.

-

Performance enhancements: Advances in carbon fiber distribution and structure may further improve the material's impact resistance and fatigue strength.

-

Customized solutions: Tailored PEEK composites can be developed to meet specific mechanical, thermal, or chemical performance requirements for different industries.

Conclusion

Long carbon fiber-reinforced PEEK combines the exceptional properties of PEEK with the reinforcing strength of long carbon fibers, offering high mechanical strength, heat resistance, chemical resistance, and lightweight characteristics. While the material is costly, it holds unmatched advantages in high-performance applications, making it a valuable composite material with great potential for future growth in demanding industries.

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文