item no.:

PA6-NA-LCFPayment:

Discussedproduct origin:

ChinaColor:

Natural color or Customizedshipping port:

XiamenLead Time:

2-10 working days

Polyamide, which is also known by the trade name, Nylon, has excellent heat resistant properties, especially when combined with additives and filler materials. In addition to this, Nylon is very resistant to abrasion. Xiamen LFT offers a wide range of temperature-resistant nylons with many different filler materials.

If you are not sure which PA material is suitable for you, please tell us your needs and our team will provide you with technical support free of charge.

What Are the Characteristics of Polyamide?

Polyamides are high-performing polymers that have great strength and wear resistance when compared to other polymers. Other notable characteristics of polyamides are:

Very good chemical resistance.

High tensile strength.

Good flexibility.

Low creep.

High impact resistance.

Prone to being hygroscopic.

What Are the Advantages of Nylon 6?

At room temperature, the tensile strength of carbon fiber modified PEEK material is doubled compared with that of non-enhanced, and it is tripled at 150℃. At the same time, the enhanced composite material has also been greatly improved in terms of impact strength, bending strength and modulus, and the elongation has been sharply reduced, and the thermal deformation temperature can exceed 300℃.The main advantages of nylon 6 are its stiffness and resistance to abrasion. Moreover, this material has excellent impact strength, wear resistance, and electrical insulating properties. Nylon 6 is a highly elastic and fatigue-resistant material, meaning it will return to its original proportions after being distorted by tension.

This polyamide is non-toxic and can be combined with glass or carbon fibers to increase performance. The absorption capacity of the material grows in direct proportion to the quantity of moisture it absorbs. The high affinity of nylon 6 for some dyestuffs allows for more dyeing diversity, with the potential for brighter, deeper patterns.

FAQ

*What processes are LFT materials suitable for?

LFT material is mainly suitable for injection molding, as well as partial extrusion. The requirements for injection molding machines are mainly reflected in the nozzle.

*Why are your products so long? Why does the material I used before, filled with glass fiber, look different than this?

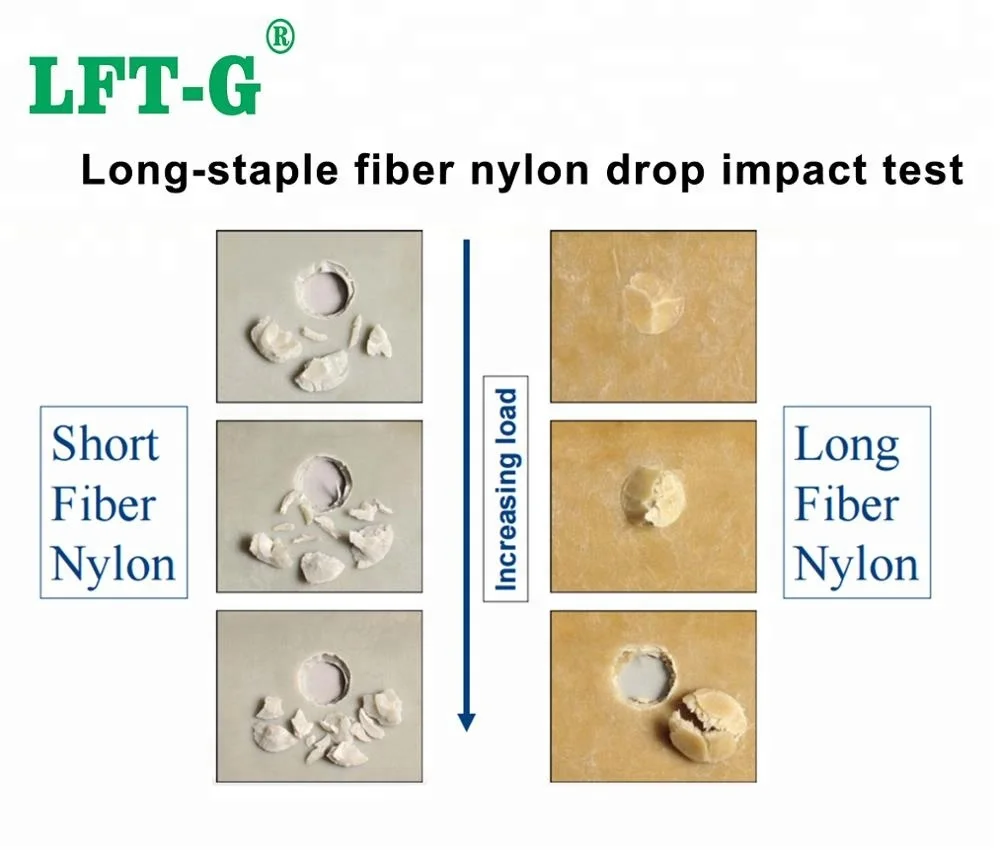

Although long fiber modified materials (LFT) and short fiber modified materials (SFT) are through the combination of fiber and resin to produce higher properties of the complex. However, the two materials are different from the production process, internal structure, appearance, performance, application and so on.

Production process: The fiber of SFT is chopped and mixed with resin, and the production process of LFT is melt impregnation.

Internal structure: The fibers inside SFT particles are short and disordered, while the fibers inside LGF are neatly arranged and longer.

Appearance: The length of SFT is usually less than 3 mm, and the length of LFT is 5-24mm.

Performance: LFT impact performance than SFT increased 1-3 times, tensile strength increased by more than 50%, mechanical properties improved by 50-80%.

Application: LFT is more suitable for use in products with high strength requirements, as load-bearing parts and structural parts.

*What is your MOQ?

MOQ is 25kg

*Do you support custom service?

Color: Please let us know which Pantone color you want to customize

Length: Lengtjh between 5mm-24mm can be customized. If there are no special requirements, the length of the plastic particles is 10-12 mm.

Our custom service is free, but the MOQ is 500kg.

*Where is your factory?

At present, our company headquarters and factory are in Xiamen, China.

We also have several offices in other provinces in China, and an exclusive agent in Turkey.