item no.:

PA6-NA-LGFPayment:

Discussedproduct origin:

ChinaColor:

Natural color or Customizedshipping port:

XiamenLead Time:

2-10 working days

|

Name |

Number |

Fiber Content |

Length |

Customization |

|

Polyamide 6 filling long glass fiber compounds |

PA6-NG-LGF | 20%-60% | 5-25mm |

Available |

|

MOQ |

Package |

Processing |

Price |

Original |

|

25kg |

25kg/bag |

Injection Molding |

Discuss |

Xiamen China |

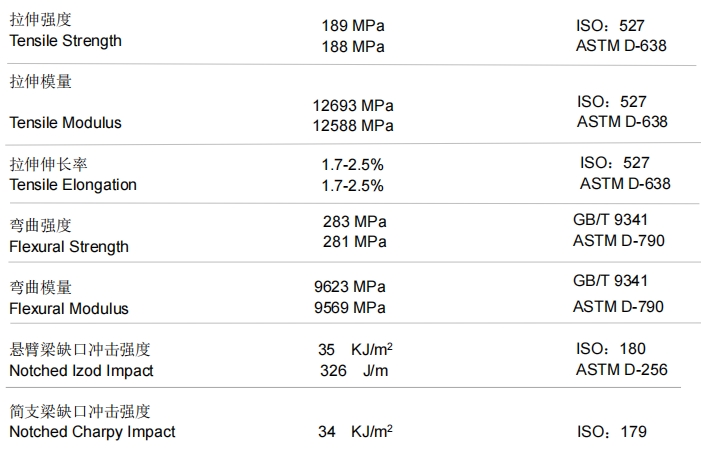

Datasheet

(For reference only)

Nylon (PA) 12 VS Nylon (PA) 6

When considering the comparison between PA 12 and PA 6, commonly known as Nylon 12 and Nylon 6, respectively, several key factors come into play.

Let's explore the differences and similarities between Nylon 12 vs Nylon 6.

Starting with the chemical structure, both PA 12 and PA 6 belong to the family of polyamides and share similar amide group (-CO-NH-) linkages. However, they differ in terms of their monomer composition and the number of carbon atoms in their repeating units. PA 12 Nylon is derived from the monomer laurolactam, while Nylon 6, or PA 6, is synthesized from the monomer caprolactam. PA 12 has a higher number of carbon atoms in its repeating unit compared to PA 6. This variation in molecular structure leads to distinct material properties and performance characteristics.

In terms of mechanical properties, PA 12 generally exhibits higher tensile strength and impact resistance than PA 6. Nylon 12's enhanced toughness and durability make it suitable for applications that require robust materials capable of withstanding mechanical stress and impact forces.

Chemical resistance is another area where PA 12 and PA 6 differ. PA 12 demonstrates superior resistance to chemicals, solvents, oils, and fuels, making it highly suitable for applications in the automotive, chemical, and oil and gas industries. On the other hand, PA 6 offers good chemical resistance but may not perform as well as PA 12 in highly aggressive chemical environments.

Thermal stability is another factor to consider. PA12 Nylon exhibits better resistance to high temperatures than PA 6. It can retain its mechanical properties and dimensional stability even at elevated temperatures, making it suitable for applications involving heat exposure.

Regarding moisture absorption, PA 12 and PA 6 demonstrate similar characteristics. Both materials have low moisture absorption rates, leading to enhanced dimensional stability in humid or wet environments.

Overall, while both PA 12 and PA 6 share the advantages of polyamides such as good mechanical properties and chemical resistance, PA 12 offers improved strength, impact resistance, chemical resistance, and thermal stability compared to PA 6.

Related product:

(Polyamide 12 filliing Long Glass Fiber Compounds)

Differences

*Focus on LFT materials. A manufacturer that produces only LFT materials

*Excellent quality. As replacement of metal and steel.

*Own-factory. 500-800 tons of production per month.

*Customization. From length to color or additives.

*Low MOQ. 20kg.

*Self laboratory. Provide TDS and COA for every batch.

*Fast shipping. Fast shipping to all capital cities or ports.

*Favorable price. Free to get price.

*Experienced team. With over 20 years experience expert team to provide assistance.

*Full service. Through product discussion, performance analysis, composite selection, composite pellet production, after-sales tracking to injection molding techniques.