item no.:

ABS-NA-LGFPayment:

Discussedproduct origin:

ChinaColor:

Natural color or Customizedshipping port:

XiamenLead Time:

2-10 working days

|

Name |

Number |

Fiber Content |

Length |

Customization |

|

ABS filling long glass fiber compounds |

ABS-NG-LGF | 20%-60% | 5-25mm |

Available |

|

MOQ |

Package |

Processing |

Price |

Original |

|

25kg |

25kg/bag |

Injection Molding |

Discuss |

Xiamen China |

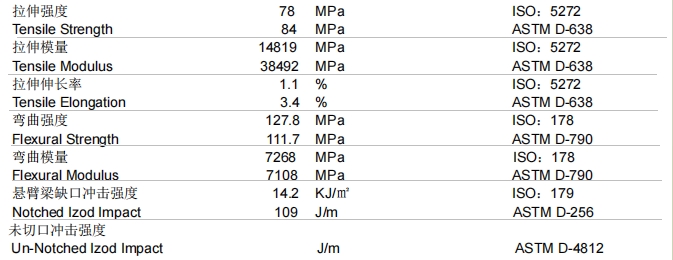

Datasheet

(For reference only)

What Are the Applications of ABS Injection Molding?

ABS is used in many different industries. Some common industries and their relevant applications are listed below.

Consumer Products: ABS is widely used in the consumer industry. Typical products include Electronic parts and so on. ABS produces a smooth, shiny surface that is impervious to dirt impregnation. ABS will react well to the inclusion of pigments and can be easily painted or even electroplated if desired.

Construction Industry: ABS is used for housings on many power tools due to its durability. Power outlet fittings are also often manufactured from ABS.

Automotive industry: ABS is typically used for parts such as: dashboards, seat belt parts, door trim, and bumpers due to its low weight, durability, and strength.

What is the ABS Injection Molding Process?

The ABS injection molding process is the same as the process involved with injection molding in most other thermoplastics.

The ABS injection molding process begins with pellets of ABS resin being fed into a hopper. The pellets are then melted and injected into a mold under high pressure. Once the molten ABS has cooled and solidified, the part is ejected from the mold and the process is repeated.

The ABS injection molding process is relatively simple and efficient, making it ideal for high-volume production runs.

ABS also has good dimensional stability and can be easily machined or drilled after molding.

Differences

*Focus on LFT materials. A manufacturer that produces only LFT materials

*Excellent quality. As replacement of metal and steel.

*Own-factory. 500-800 tons of production per month.

*Customization. From length to color or additives.

*Low MOQ. 20kg.

*Self laboratory. Provide TDS and COA for every batch.

*Fast shipping. Fast shipping to all capital cities or ports.

*Favorable price. Free to get price.

*Experienced team. With over 20 years experience expert team to provide assistance.

*Full service. Through product discussion, performance analysis, composite selection, composite pellet production, after-sales tracking to injection molding techniques.