item no.:

ABS-NA-LGFPayment:

Discussedproduct origin:

ChinaColor:

Natural color or Customizedshipping port:

XiamenLead Time:

2-10 working days

Glass fiber reinforced ABS modified plastic, as a kind of engineering plastic composite material, combines the advantages of ABS plastic (acrylonitrile-butadiene-styrene copolymer) and glass fiber, and significantly improves the properties of the material. It has a wide range of applications in many fields, especially in the automobile, electronics, home appliances and other industries, playing an irreplaceable role.

The main application scope of modified ABS:

1. Auto parts: instrument panels, fenders, car interiors, car lights, reversing mirrors, car audio;

2. Electronic and electrical components: IT equipment, OA equipment shells, converters, etc., power sockets, etc.;

3. Electronic appliances: switches, power switches, controllers, monitors, monitor housings, electrical housings, electrical brackets;

4. Home appliances: electrical components, electrical control boxes

FAQ

*What processes are LFT materials suitable for?

LFT material is mainly suitable for injection molding, as well as partial extrusion. The requirements for injection molding machines are mainly reflected in the nozzle.

*Why are your products so long? Why does the material I used before, filled with glass fiber, look different than this?

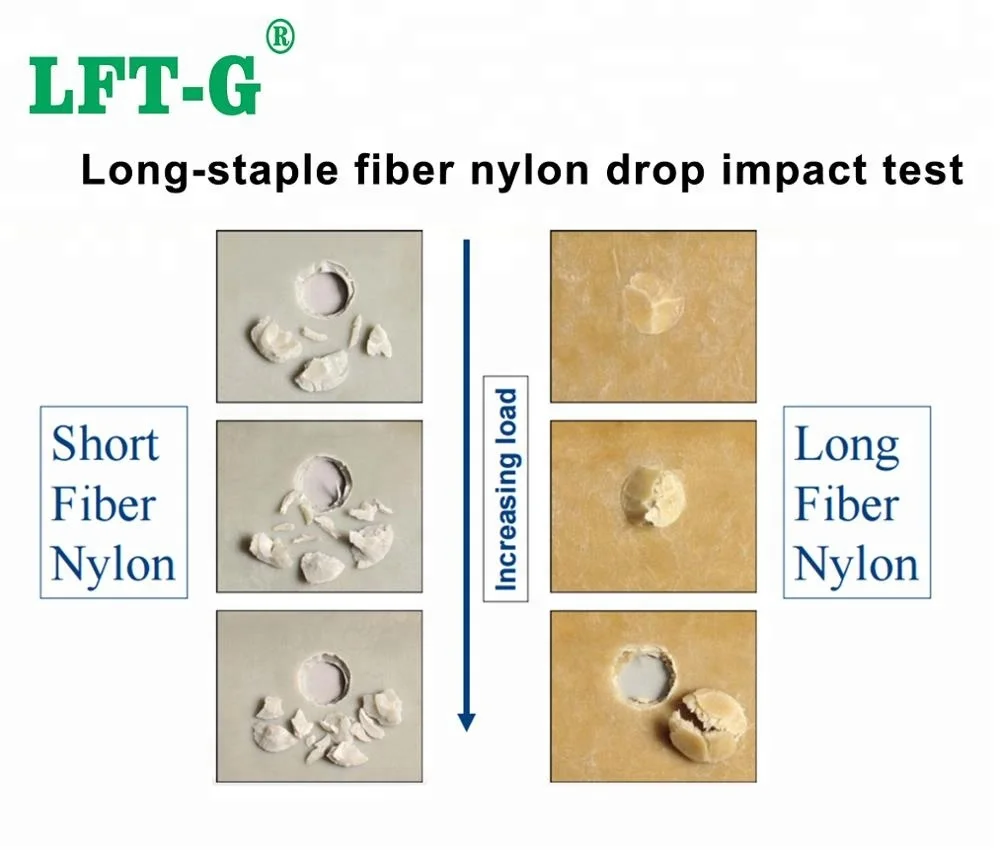

Although long fiber modified materials (LFT) and short fiber modified materials (SFT) are through the combination of fiber and resin to produce higher properties of the complex. However, the two materials are different from the production process, internal structure, appearance, performance, application and so on.

Production process: The fiber of SFT is chopped and mixed with resin, and the production process of LFT is melt impregnation.

Internal structure: The fibers inside SFT particles are short and disordered, while the fibers inside LGF are neatly arranged and longer.

Appearance: The length of SFT is usually less than 3 mm, and the length of LFT is 5-24mm.

Performance: LFT impact performance than SFT increased 1-3 times, tensile strength increased by more than 50%, mechanical properties improved by 50-80%.

Application: LFT is more suitable for use in products with high strength requirements, as load-bearing parts and structural parts.

*What is your MOQ?

MOQ is 25kg

*Do you support custom service?

Color: Please let us know which Pantone color you want to customize

Length: Lengtjh between 5mm-24mm can be customized. If there are no special requirements, the length of the plastic particles is 10-12 mm.

Our custom service is free, but the MOQ is 500kg.

*Where is your factory?

At present, our company headquarters and factory are in Xiamen, China.

We also have several offices in other provinces in China, and an exclusive agent in Turkey.