item no.:

PBT-NA-LGFPayment:

Discussedproduct origin:

ChinaColor:

Natural color or Customizedshipping port:

XiamenLead Time:

2-10 working days

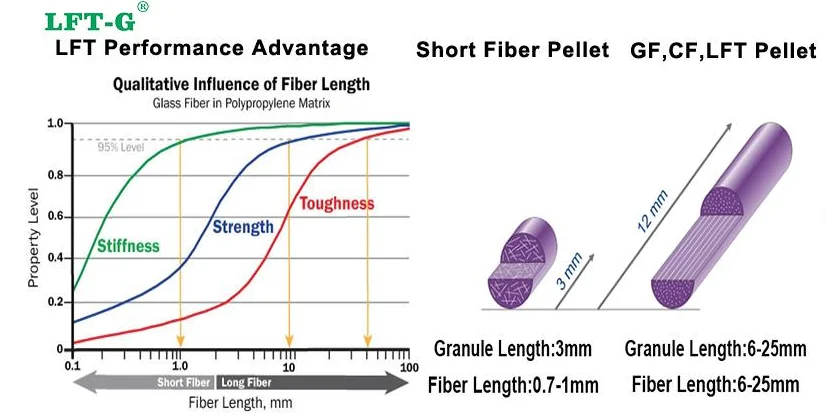

When PBT is combined with glass fiber, it will produce the following effects:

1. Enhance strength and stiffness: Glass fiber has excellent strength and stiffness, and adding it to PBT can significantly increase the mechanical properties of plastics. This makes the PBT plus glass fiber material stronger and more rigid when bearing force or stress, and is less likely to deform or break.

2. Improve heat resistance: Glass fiber has a higher melting point and has good heat resistance. When glass fiber is added to PBT, it can improve the heat resistance of PBT, allowing it to maintain better performance at higher temperatures and prevent softening or melting.

3. Improve corrosion resistance: Glass fiber has excellent corrosion resistance, and adding it to PBT can improve its resistance to chemicals, solvents and other corrosive media. This allows the PBT plus glass fiber material to have a longer service life in some special environments.

4. Improve insulation performance: PBT itself has good insulation performance, and the addition of glass fiber further improves the insulation performance of PBT material. This makes PBT plus glass fiber materials more suitable for electrical and electronic applications, which can effectively isolate current and reduce leakage and electromagnetic interference.

Outstanding benefits of PBT LGF

One of the remarkable features of PBT-LGF is its excellent dimensional stability. The presence of glass fibers greatly reduces the material's tendency to expand or contract under varying temperature conditions. This property ensures that PBT LGF retains its shape and size, making it suitable for applications that demand tight tolerances and precise dimensions.

PBT LGF exhibits exceptional creep resistance, meaning it maintains its shape and dimensional stability even under long-term mechanical stress or constant load. This property makes it highly suitable for applications that involve sustained loads or extended use, ensuring the integrity and longevity of the component.

Despite its impressive mechanical properties, PBT LGF remains lightweight. The addition of glass fibers provides strength without significantly increasing the material's weight. This lightweight characteristic makes it advantageous in industries where weight reduction is crucial, such as automotive, aerospace, and consumer electronics.

PBT-LGF offers excellent design flexibility due to its ability to be molded into complex shapes and intricate details. The material's flowability allows for the production of intricate parts with high precision, enabling designers to create innovative and functional designs that meet specific requirements.

PBT-LGF exhibits an excellent surface finish, allowing for high-quality aesthetics. The material can be easily molded to achieve smooth surfaces, reducing the need for post-processing or additional finishing steps. This feature is especially beneficial in applications where visual appeal is important, such as consumer products and automotive interior components.