-

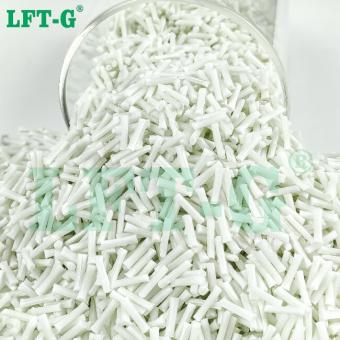

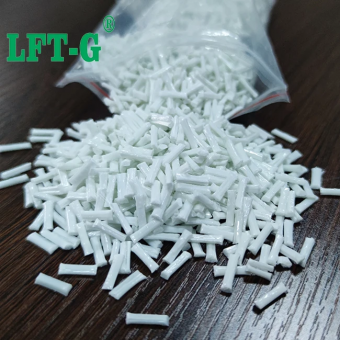

LFT material Thermoplastic Polyurethane resin with filler Glass Fiber compoundsThermoplastic Polyurethane is soft and elastic, with excellent tensile and tear strength.

- TPU filament composites granules

- long glass fiber reinforcement polymer

- High toughness enhanced plastic fiberglass

- engineering use LFT manufacturer producer

- thermoplastic resin customize raw materials

- shoes parts sole toy automotive

Tags :

-

LFT material Polypropylene Copolymer resin with filler Glass Fiber compoundsPolypropylene, also known as PP or polypropene, is a polyolefin or saturated polymer.view more

-

LFT material ABS resin with filler Glass Fiber compounds for electronial partsABS is a thermoplastic polymer that is durable and easy to work with.

- Acrylonitrile Butadiene Styrene filament composites granules

- home appliance parts E&E electrical

Tags :

-

Xiamen LFT high strength PBT reinforced plastic Long Glass Fiber filled compoundsPBT materials Polybutylene terephthalate (PBT) is a thermoplastic polyester and one of the top five engineering plastics. PBT has excellent overall performance, is one of the toughest engineering plastics, and has high dimensional stability, good chemical resistance, excellent electrical insulation, good mechanical properties and elasticity, low water absorption, etc. PBT filling Long glass fiber compounds PBT (polybutylene terephthalate) is a polyester-based plastic, while glass fiber is a reinforcing material that is usually added to plastics in fiber form to enhance their mechanical properties. When PBT is combined with glass fibers, the following effects occur: 1. Enhanced strength and stiffness: glass fiber has excellent strength and stiffness, and adding it to PBT can significantly increase the mechanical properties of the plastic. This makes the material of PBT with glass fiber more strong and rigid when it is subjected to force or stress, and less likely to deform or break. 2. Improve heat resistance: glass fiber has a high melting point and good heat resistance performance. When glass fiber is added to PBT, it can improve the heat resistance of PBT, so that it can keep better performance at higher temperature and prevent softening or melting. 3. Improve corrosion resistance: Glass fiber has excellent corrosion resistance, and adding it to PBT can improve its resistance to chemicals, solvents and other corrosive media. This makes PBT with glass fiber have longer service life in some special environments. 4. Improve insulation performance: PBT itself has good insulation performance, and the addition of glass fiber further improves the insulation performance of PBT material. This makes the PBT with glass fiber more suitable for electrical and electronic applications, which can effectively isolate the current and reduce leakage and electromagnetic interference. All in all, PBT with glass fiber can enhance the mechanical properties, heat resistance, corrosion resistance and insulation properties of plastics, making them more widely used in various applications. However, the performance of the material may vary depending on the specific glass fiber content and the addition process. Fiber specification Grade Fiber specification Characteristics Application Length Color Package General grade 20%-60% High toughness, Low warpage Electronic appliances, mechanical parts, etc. About 12mm, or customzied Natural color, or customized 25kg/bag The difference between LGF & SGF Short glass fiber particles: Size size is about 3-4mm, length to width ratio 50-250 Long glass fiber particles: Size is about 10-12mm, aspect ratio >400 In addition, the distribution of glass fiber in the two kinds of particles is also different. Compared with SGF, the rigidity, strength and modulus of LGF have been improved, especially the notched impact performance has got a qualitative leap. Application Datasheet for reference About us Xiamen LFT composite plastic Co., Ltd. is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) & Long Carbon Fiber Series (LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm length. The company's long-fiber continuous infiltration reinforced thermoplastics have passed ISO9001&16949 system certification, and the products have obtained lots of national trademarks and patents.

- PBT reisn composite lgf 30 best price

- long glass fiber reinforced pbt for auto parts

- virgin white pbt can be recycled lgf

- thermoplastic plastic pbt lft made in China whole sell

- high performance pbt with filler lgf

- PBT composite plastic manufacturert direct sell

Tags :

-

LFT material Polypropylene Copolymer resin with filler Glass Fiber compoundsPolypropylene, also known as PP or polypropene, is a polyolefin or saturated polymer.view more

-

LFT Polyamide 6 High Performance Filled Long Glass Fiber ReinforcementThe main benefits of using polyamide are its low cost combined with its desirable mechanical and chemical properties.

- Nylon 6 PA6 modified resin composites

- Injection mold plastic reinforced with filler

- engineering use automotive parts

- Long fiber glass fiberglass carbon fiber add

- High strength and toughness low warping

- China manufacturer good price

Tags :

-

LFT Polyamide 66 High Strength and Stiffness Long Glass Fiber reinforcementNylon 66 for machining has improved temperature resistance and lower rates of water absorption when compared to standard nylon 6.

- High-performance nylon composites

- Long glass fiber PA66 applications

- Engineering thermoplastics

- Lightweight automotive materials

- Glass fiber reinforced polyamide durability

- Injection molding nylon 66 composites

Tags :

-

LFT Polyamide 12 high performance long glass fiber reinforcementPA 12 GF30 is a type of engineering plastic that consists of polyamide 12 (PA 12) compounds reinforced with 30% glass fibers.

- High strength polyamide 12 composites

- Lightweight glass fiber PA12

- Durable PA12 reinforced with glass fibers

- PA12 GF for automotive applications

- Thermoplastic composite materials PA12 GF

- Injection molding PA12 glass fiber

Tags :

-

LFT-G TPU Thermoplastic Urethane long glass fiber reinforced compoundsCharacteristic Unit Test Method Property Value Specific Gravity g/cm³ ASTM D-792 1.51 Molding Shrinkage % ASTM D-955 Tensile Strength MPa ASTM D-638 220 Tensile Modulus MPa ASTM D-638 11720 Tensile Elongation % ASTM D-638 2.0-3.0 Flexural Strength MPa ASTM D-790 310 Flexural Modulus MPa ASTM D-790 9650 Notched Izod Impact KJ/m2 ASTM D-256 569 Notched Charpy Impact KJ/m2 ASTM D-4812 1469 Deflection Temperature °C ASTM D-648 For reference only Why choose LFT Materials? Long glass fiber reinforced composites can solve your problems when other methods of reinforced plastics do not provide the performance you need or if you want to replace metal with plastic. Long glass fiber reinforced composites can cost-effectively reduce the cost of goods and effectively improve the mechanical properties of engineering polymer .Long fibers can be uniformly distributed inside the product to form a network skeleton, thus improving the mechanical properties of the material product. Long fiber reinforced thermoplastics properties - Strong yet ductile fiber option - Exceptional toughness retained at low and elevated temperatures - High fatigue and creep endurance - Mechanical property retention at low and elevated temperatures - Colorable for product branding or quick identification - Go-to material for metal replacement with favorable economics - Greater properties than short fiber/chopped glass fiber filled compounds Key Long Fiber Reinforced Thermoplastics Uses: - Auto interior trim - Automotive engine compartment covers - Car chassis - Car engine - Consumer goods - Enclosure and frame - Furniture - Medical - Power tools - Sport - EBikes Xiamen LFT has capabilities to provide assistance to you throughout an entire product launch - through product discussion, performance analysis, composite selection, composite pellet production, after-sales tracking. In addition, we provide guidance on injection molding techniques

- TPU glass fiber reinforced properties

- Long fiber thermoplastic composites

- High strength TPU composites

- Glass fiber reinforced TPU applications

- TPU compound mechanical properties

- Injection molding TPU glass fiber

Tags :

-

LFT Polyphenylene Sulfide engineering plastic with long glass fiber reinforcementPure PPS is rarely used alone due to its brittle performance. Most of the PPS used is its modified variety. Glass fiber reinforced PPS is one of them.

- Long fiber PPS applications

- PPS mechanical properties

- PPS electrical insulation

- Glass fiber PPS

- Long Fiber Reinforced PPS

- PPS thermal resistance Chemical resistant

Tags :

-

LFT PBT long glass fiber reinforced thermoplastic virginal granulesKnown for its dimensional stability, low moisture absorption, high strength, stiffness, and chemical, UV, and thermal resistance.

- Glass Fiber Reinforced PBT applications

- PBT vs PET

- PBT with glass fiber properties

- PBT molding guidelines

- Reinforced thermoplastics market trends

- injection molding materials LFT-G

Tags :

-

LFT Polyphthalamide PPA Long Glass Fiber reinforced thermoplastic resinMost PPA are filled with glass fiber or carbon fiber to enhance stiffness for high-temperature applications. As a result, PPA is often used in applications in place of metal or higher-priced thermoplastic.

- Glass Fiber Reinforced PPA applications

- PPA long glass fiber mechanical properties

- PPA glass fiber reinforcement benefits

- High-performance PPA materials

- PPA composites for automotive parts

- Durability of long glass fiber reinforced PPA

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文