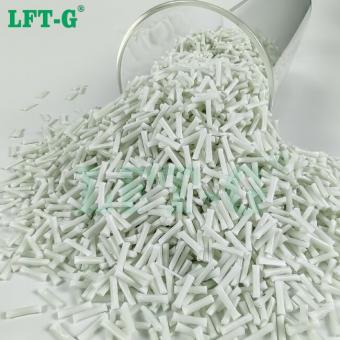

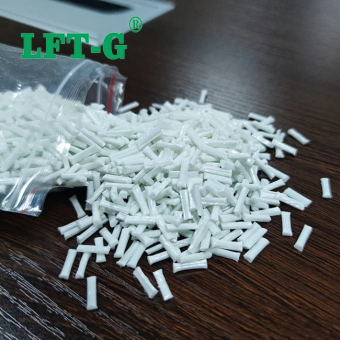

Long glass fiber has high strength, high rigidity, corrosion resistance, harsh environment suitability and low cost. When the resin matrix is impregnated and extruded into pellets ,Also called Long Glass Fiber Polymer it has good mechanical properties.

-

Reinforced HDPE-LGF High Toughness Structural MaterialThis high-performance composite material is based on High-Density Polyethylene (HDPE) reinforced with long glass fibers (LGF) through continuous pultrusion technology. It is specially engineered to overcome the mechanical limitations of traditional HDPE by significantly enhancing its strength, stiffness, and dimensional stability — while retaining the excellent chemical resistance and low density of HDPE.

- fiber reinforced hdpe composite pipe

- hdpe glass

- lft g for automobile market

- metal replacement solutions

- thermoplastic composite materials

Tags :

-

High-Strength PBT Composite for Advanced Structural ApplicationsOur PBT Long Glass Fiber Reinforced Structural Composite Material combines high-performance Polybutylene Terephthalate (PBT) resin with long glass fiber (LGF) to create a material that delivers exceptional strength, heat resistance, and dimensional stability. This advanced material is designed for demanding applications in industries such as automotive, electronics, and industrial machinery.

- pbt properties

- lft plastic

- lft container color

- pbt fiber

- polymer price per kg

- wholesale glass fiber reinforced plastic resin dispenser in china

Tags :

-

MXD6 Reinforced Composite for High-Strength Structural ApplicationsThis product is based on MXD6 (meta-xylylene adipamide) resin, reinforced with long glass fiber (LGF) using advanced pultrusion technology. It is a high-performance engineering thermoplastic known for its exceptional gas barrier properties, high strength, and dimensional stability. MXD6-LGF combines rigidity, toughness, and thermal resistance, making it ideal for demanding structural applications in automotive, electronics, industrial machinery, and barrier-sensitive components.

- types of fibers in composites

- thermoplastic fiber

- long fiber thermoplastic

- fiber forms

- mxd6

- long fiber

Tags :

-

Eco-Performance PLA-LGF Long Glass Fiber Reinforced BiocompositeThis material is a biodegradable composite made from Polylactic Acid (PLA) resin reinforced with long glass fibers (LGF). It is developed through advanced pultrusion technology to improve mechanical strength, heat resistance, and dimensional stability — all while maintaining environmental sustainability. It is ideal for applications seeking a balance between performance and eco-friendliness.

- polylactic acid pellets

- long fibre reinforced pellets

- pla plastic pellets

- composites non-destructive testing

- gfrp price per kg

Tags :

-

High-Strength ABS-LGF Structural Composite MaterialThis high-performance material is a composite of Acrylonitrile Butadiene Styrene (ABS) reinforced with long glass fiber (LGF), engineered through advanced pultrusion technology. Designed for enhanced structural strength and durability, it is ideal for load-bearing applications where traditional ABS falls short.

- abs granules manufacturer

- abs gf

- abs for home appliance

- composite wind turbine blades

- essential polymers

- natural abs color

Tags :

-

High Heat Resistant and High Strength PPA LGF Composite MaterialThis product is based on high-performance Polyphthalamide (PPA) resin, reinforced with long glass fibers (LGF) and engineered through advanced compounding technology. It combines excellent mechanical strength, thermal resistance, chemical stability, and dimensional accuracy. It is ideal for demanding structural applications in the automotive, electrical, industrial, and consumer sectors—especially where metal replacement is needed.

- wholesale glass fiber

- g ppa

- lft kft

- thermoplastic composites applications

- oem ppa fiber

- metal replacing materials

Tags :

-

New Materials LGF PPS Glass Fiber High Toughness Engineering UseThis product uses high-performance Polyphenylene Sulfide (PPS) resin combined with long glass fiber (LGF) reinforcement, modified with patented toughening technology. It offers outstanding mechanical properties, high temperature resistance, and dimensional stability. It is widely used in industries such as automotive, electronics, and machinery, particularly for high-strength, high-temperature, and impact-resistant structural parts.

- glass fiber reinforced plastic

- glass fiber reinforcement filler

- glass toughening plant

- PPS GF

- good composites for injection molding

- pps lft

Tags :

-

New Materials LGF PBT High Toughness for Widely UseOur Long Glass Fiber Reinforced PBT is a high-performance thermoplastic composite material combining the dimensional stability and thermal resistance of PBT with the strength and durability of long glass fibers. It is ideal for structural parts that require excellent mechanical strength, thermal stability, and electrical insulation.view more

-

New Materials LGF TPU High Tensile for Widely UseOur TPU Long Glass Fiber Reinforced Material is a high-performance thermoplastic solution that blends the flexibility of TPU with the strength of long glass fibers. This innovative material delivers enhanced mechanical performance while maintaining excellent elasticity and surface aesthetics — making it ideal for applications where durability meets design.

- tpu recycle

- tpu plastic pellets

- china tpu supplier

- glass fiber filled tpu

- tpu pellets

- tpu resin

Tags :

-

New Materials LGF Polyamide 12 Nylon for Structural ApplicationsOur Long Glass Fiber Reinforced PA12 offers exceptional mechanical strength, impact resistance, and chemical stability — making it the ideal material for precision parts used in demanding environments. With a naturally low water absorption rate and excellent dimensional stability, this advanced composite ensures reliability even under extreme conditions.view more

-

New Materials LGF Polyamide 66 Nylon for Structural ApplicationsOur PA66 Long Glass Fiber Reinforced Material is a high-performance thermoplastic composite developed for applications demanding superior mechanical strength, dimensional stability, and heat resistance. Ideal for metal replacement and high-load structural components.view more

-

Advanced LGF Polyamide 6 Nylon for Structural ApplicationsOur PA6 Long Glass Fiber Reinforced Material is engineered to deliver exceptional strength, thermal stability, and impact resistance—making it the ideal alternative to metal for lightweight, high-performance components across multiple industries.view more

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文