Why Choose Our Material?

High Strength & Stiffness:

Long glass fiber reinforcement greatly improves tensile and flexural performance, making HDPE suitable for structural use.

Excellent Impact Resistance:

Toughened to absorb impact without cracking, even in low temperatures or rugged environments.

Superior Chemical & Corrosion Resistance:

Maintains performance in contact with water, fuels, salts, acids, and alkalis.

Low Density & Lightweight:

Provides a strength-to-weight ratio ideal for replacing metal or traditional plastic in large components.

Good Dimensional Stability:

Improved resistance to deformation, warpage, and shrinkage under load or heat.

Endless Possibilities Across Industries

Automotive & Transportation:

Mudguards, underbody shields, seat structures.

Water & Waste Management:

Pump housings, pipe fittings, pressure-resistant containers.

Agriculture & Infrastructure:

Equipment panels, structural reinforcements, outdoor units.

Consumer Goods:

Tough lightweight parts for sports gear, cases, and tools.

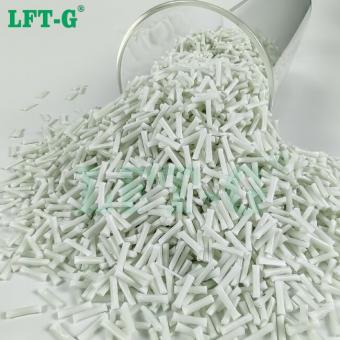

Key Specifications

Base Material: Polybutylene terephthalate

Glass Fiber Content: 20%-60%

Tensile Strength: 178 MPa (MAX)

Flexural Strength: 264 MPa (MAX)

Density: 1.72 g/cm³

Certified Quality, Proven Performance

ISO 9001: Quality Assurance

ISO 14001: Environmental Compliance

UL Listed: Trusted in global markets

Packaging & Delivery

Packaging: 25kg/bag, available in aluminum foil bag.

Lead Time: 2–5 business days for regular orders; customized orders can be negotiated.

Port of Shipment: Xiamen Port, China.

Ready to Upgrade Your Materials?

Get in touch to discuss how our Material can revolutionize your projects.

Contact Engineers

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文