item no.:

CPP-NA-LGFPayment:

Discussedproduct origin:

ChinaColor:

Natural color or Customizedshipping port:

XiamenLead Time:

2-10 working days

Where Are Copolymers Used?

Copolymers can be found in many industries, including in: Car parts, washing machine parts,

water pump parts, water treatment components, furniture parts, etc.

Which Is Better, Homopolymer or Copolymer?

It depends. Neither homopolymer nor copolymer is better than the other. It will depend on the application as to which is more desirable. Homopolymers are better suited to high-strength and high-hardness applications, whereas copolymers are suited for corrosion resistance and high operating temperatures. Although a raw homopolymer has better mechanical properties, copolymers have better mechanical properties when reinforced with glass over glass-reinforced homopolymer. This is because copolymers are better suited to adhering to fibers.

After Filling Glass Fiber

Combining the flexibility of Polypropylene and the properties of fiberglass, PP-GF Compound material increases performance and brings reliability to the market.

Hardness: This is the most outstanding feature of PP engineering plastic compounds because they are combined with glass fiber. Glass fiber will be added according to the level based on customer needs such as: PP-GF30 Compound (30%), PP-GF20 Compound (20%) and so on. Glass fiber improves the tensile strength, high bearing capacity and temperature stability of the material. They are suitable for use in heavy industries.

Maintains dimensional stability: Compared to traditional Polypropylene lines, the dimensional stability of PP-GF Compound is much superior. Conditions such as deformation, cracking, warping or shrinkage will be completely eliminated because of the properties of fiberglass and the hardness of the material.

High temperature resistance level: The heat resistance level of PP-GF Compound plastic is about 100 degrees Celsius for long periods of time and 150 degrees Celsius for short periods of time. In particular, they are not deformed and can continue the machining process immediately afterwards. Therefore, PP-GF Compound plastic is used to produce products for outdoor use.

Avoid impacts from strong chemicals: PP-GF Compound plastic can resist strong chemicals such as: Acids, solvents, kerosene,...

Light weight: The original weight of Polypropylene is quite light. In particular, this nature is not lost when they are combined with fiberglass. PP-GF Compound plastic is not only light but also very durable. Therefore, they are suitable in industries such as automobiles, aerospace, heavy industry,...

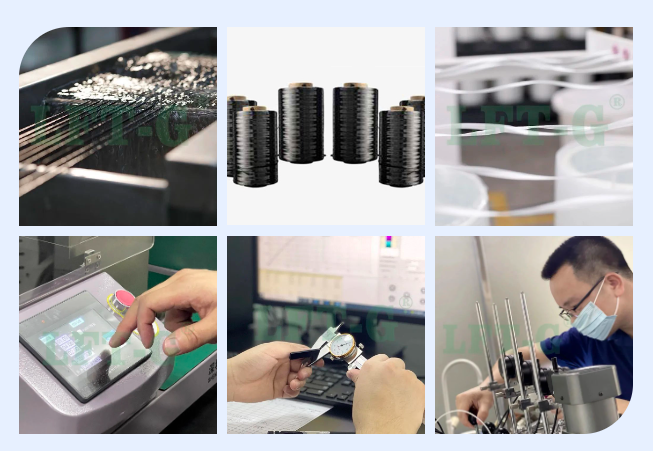

Production Process

1. Through the physical and chemical treatment of the original carbon fiber, it removes impurities, improves surface activity, and provides the mechanical properties and durability of pre-soaked materials.

2. Add resin, additives, etc., form a unique formula. Improve flowability, hardness, temperature stability.

3. The pre-treated carbon fiber is placed on the machine, and the resin is evenly covered on its surface.

4. Use the machine to solidify the material, and the fiber and resin are both sufficiently bonded.

5. According to the requirements of the product, cutting particles.

Long glass fiber reinforced composites can solve your problems when other methods of reinforced plastics do not provide the performance you need or if you want to replace metal with plastic. Long glass fiber reinforced composites can cost-effectively reduce the cost of goods and effectively improve the mechanical properties of engineering polymer .Long fibers can be uniformly distributed inside the product to form a network skeleton, thus improving the mechanical properties of the material product.

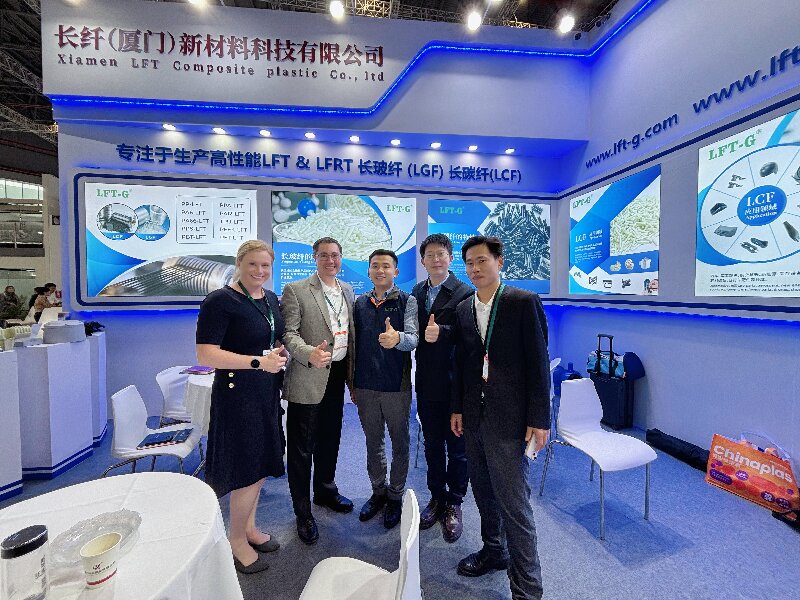

About Us

Xiamen LFT has capabilities to provide assistance to you throughout an entire product launch - through product discussion, performance analysis, composite selection, composite pellet production, after-sales tracking. In addition, we provide guidance on injection molding techniques