-

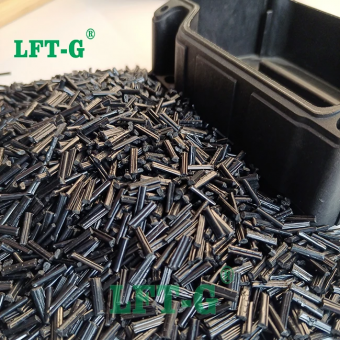

LFT Polypropylene PP filling long glass fiber 20%-60% high performance thermoplastic resinPP material Polypropylene, PP for short, is a polymer of propylene by adding polymerization. White waxy material, transparent and light in appearance. Polypropylene is a thermoplastic synthetic resin with excellent properties. It is a colorless translucent thermoplastic lightweight general plastic with chemical resistance, heat resistance, electrical insulation, high strength mechanical properties and good high wear-resisting machining properties. PP-LGF material PP plus glass fiber is by adding glass fiber reinforced PP material, due to the addition of glass fiber, limited the mutual movement between polymer chains of PP plastic, therefore, the shrinkage rate of glass fiber reinforced PP (PP plus glass fiber) decreases, rigidity, impact resistance, tensile strength, compression strength, bending strength and flame retardant are improved. The mechanical properties of PP plus glass fiber specifically, tensile strength reached 65MPa--90MPa, bending strength reached 70MPa--20MPa, bending modulus reached 3000MPa--4500MPa, such mechanical strength can be completely comparable with ABS and enhanced ABS products, and more heat resistant. Generally, the heat resistance temperature of ABS and reinforced ABS is between 80℃--98℃, and the heat resistance temperature of glass fiber reinforced PP material can reach 135℃--145℃, and even 150 degrees can withstand more than 1000 hours. Compared with SGF(Short Glass Fiber) TDS for reference only Application of PP-Long glass fiber PP filling long glass fiber material, can be used to make refrigerators, air conditioning and other refrigeration machines in the axial flow fan and fan. In addition, it can also be used to manufacture the inner drum of high speed washing machine, wave wheel, belt wheel to adapt to its high mechanical performance requirements, used for rice cooker base and handle, electronic microwave oven and other places with high temperature resistance requirements, generally speaking, most glass fiber reinforced PP material is used in the structural parts of the product, is a kind of structural engineering materials. Cases Washing machine parts Automobile front end parts Scooter parts Frequently asked questions 1. Does long glass fiber injection have special requirements for injection molding machines and molds? A. There are certainly requirements. Especially from the product design structure, as well as the injection molding machine screw nozzle and mold structure injection molding process must consider the requirements of long fiber. 2. After long glass fiber reinforced, glass fiber can enter the surface of the plastic product during injection molding process, so that the surface of the product become rough and floating fiber. How to make the surface of the material smoothly? A. During injection molding process need to ensure that the plastic particles are well plasticized and dispersed, also ensure that the drying of plastic particles have no moisture removal, mold temperature adjustment to the appropriate temperature, mold surface is polished in place. 3. Can products with appearance requirements be made of long-fiber materials? A. The main feature of LFT-G thermoplastic long glass fiber and long carbon is to show the mechanical properties. If the customer has bright or other requirements for the appearance of the product, it needs to be evaluated in combination with specific products,

- long fibre reinforced thermoplastics

- long fiber compounds pp

- pp lgf40

- long glass fiber polypropylene

- long fiber composite PP granules

- PP LFT Compounds polymers

Tags :

-

Xiamen LFT Polyetheretherketone CF composite 20%-60% high performance natural colorProduct grade: General grade Fiber specification: 20%-60% Product feature: Flame resistant, Heat resistant, Chemical resistant, Low friction coefficient, Good load bearing Product application: Aviation, Machinery, Electronics, Chemicals, Automotive, Other high-tech fields.

- Good load bearing polyetheretherketone

- Low friction coefficient made bu own factory

- Own factory made pure and virgin peek

- Wide useage peek industrial materials reinforced peek

- Customized materials peek toughness Carbon

- Long Glass Fiber can be recycled peek aerospace

Tags :

-

LFT Polyphenylene sulfide PPS Long Glass fiber Reinforced PPS PelletsEngineer PPS filled Long Glass fiber Reinforcedis one kind of engineering modifeid plastic materials of long glass fiber reinforced PPS

- PPS filled Long glass fiber

- Polyphenylene sulfide PPS anti aging

- PPS Polymer pellets

- Modified PPS

- Thermoplastic Reinforced plastic PPS

Tags :

-

Xiamen LFT MXD6 resin long glass fiber reinforcement polymer compoundsMXD6 resin granules filling long glass fiber compounds pellets factory price

- MXD6 resin polymer thermoplastic

- MXD6 pellets made in China

- MXD6 polymer imdustrial use good price

- plastic raw material MXD6 GF30 glass fiber

- MXD6 granules reinforced plastic

- plastic MXD6 lgf40 sample available

Tags :

-

LFT-G modified ABS compounds Long Glass Fiber for automotive partsABS material Acrylonitrile-butadiene styrene (ABS) resin is an opaque amorphous thermoplastic engineering plastic with complex two-phase structure. It is composed of styrene, acrylonitrile and butadiene in different proportions. In the 1970s, it began to be recognized by the public and began to be used. In the 1990s, the market demand grew rapidly. At present, it should be used in domestic and foreign markets, especially in construction, home appliances, automobiles and other industries. ABS-LGF Long glass fiber is widely used in engineering plastics. Reinforced ABS composites are made by adding a certain percentage of glass fiber, with the addition of 30% to 50% glass fiber being the most common. So as to improve the mechanical properties of ABS. Such as tensile properties, bending properties, and the corresponding molding shrinkage rate is not reduced, so that the material will not stress cracking. Advantages: 1. Long glass fiber reinforced, glass fiber is a high temperature resistant material, therefore, the heat resistant temperature of reinforced plastic is much higher than before without glass fiber, especially nylon plastics 2. After long glass fiber reinforcement, due to the addition of long glass fiber, the mutual movement between polymer chains of plastic is limited, therefore, the shrinkage rate of reinforced plastics decreases a lot, and the rigidity is greatly improved. 3. After long glass fiber reinforcement, reinforced plastics will not stress crack, at the same time, the anti-impact performance of plastics is improved a lot. 4. After long glass fiber reinforcement, glass fiber is a high strength material, which also greatly improves the strength of plastic, such as: tensile strength, compression strength, bending strength, improve a lot. 5. Long glass fiber reinforced after, due to the addition of glass fiber and other additives, the combustion performance of reinforced plastics decreased a lot, most of the material can not ignite, is a kind of flame retardant material. Datasheet for reference only Processing flow Cases About Xiamen LFT-G Xiamen LFT composite plastic Co., Ltd. is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series(LGF) & Long Carbon Fiber Series(LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm length. The company's long-fiber continuous infiltration reinforced thermoplastics have passed ISO9001 & 16949 system certification, and the products have obtained lots of national trademarks and patents.

- Modified material lft injection molding

- ABS compounds long glass fiber

- lgf injection mold abs for engineering

- reinforced material abs filling lgf

- ABS-LGF30 thermoplastic resin

- Thermoplastic resin ABS

Tags :

-

Xiamen LFT-G reinforced Polyphthalamide filling long glass fiber injection moldingPPA-LGF PPA, full name polyphthalamide, is a semi-aromatic polyamide with no less than 55% terephthalic acid or phthalic acid as raw material, commonly known as aromatic high temperature nylon. PPA has better mechanical properties and high temperature resistance compared to traditional aliphatic nylon (PA6/PA66) materials. PPA materials have relatively low water absorption, good dimensional stability and good corrosion resistance. Glass fiber reinforced PPA composites have high temperature resistance, high strength and low density, and are considered to be the best resin to replace steel with plastic. Compared with traditional short fiber reinforced pellets, long glass fiber reinforced PPA composites have better physical and mechanical properties. Application Because high-temperature nylon can withstand high strength, high loads, and high temperatures in harsh environments, it is ideal for applications in engine areas (such as engine covers, switches, and connectors) as well as transmission systems (such as bearing cages), air systems (such as exhaust control systems), and air intake units. PPA engineering plastic is a high performance engineering plastic reinforced by fiber with high temperature nylon as the base material. The structure and crystalline characteristics of high-temperature nylon make it have more characteristics and excellent overall performance than nylon 66 and nylon 6 and other engineering plastics: strong rigidity, high hardness, high temperature resistance, good chemical resistance and low water absorption, dimensional accuracy and stability and low warpage, excellent fatigue resistance, in many fields including automotive parts, mechanical parts and electrical and electronic parts used in motor parts It is widely used in many fields including automotive parts, mechanical parts and electrical and electronic parts for motor parts, circuit breakers, etc. Other materials you may wonder About us Xiamen LFT composite plastic Co., Ltd is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) & Long Carbon Fiber Series (LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm in length. The company's continuous infiltration reinforced thermoplastics have passed ISO9001&16949 system certification, and the products have obtained lots of national trademarks and patents. We will offer you 1. LFT&LFRT material technical parameters and leading edge design 2. Mold front design and recommendations 3. Provide technical support such as injection molding and extrusion molding

- ppa granules lgf30 GF PPA virgin grade

- best long glass fiber ppa lgf30 granules

- Polymer lgf PPA Virgin pure materials

- pla lgf30 pla granule price good price

- ppa granules lgf30 self factory made

- ppa lft glass fiber fiberglass modified plastic

Tags :

-

Xiamen LFT MXD6 filling Long glass fiber high toughness injection moldingMXD6 Polyadipyl-m-benzoylamine, abbreviated as mxd6, resin has higher mechanical strength and modulus than other engineering plastics, is also a special high barrier nylon material. Although the barrier of mxd6 is slightly worse than that of pvdc and evoh, its barrier is not affected by temperature and humidity, which is especially suitable for high temperature and humid occasions. In today's barrier packaging and plastic instead of steel general trend, nylon mxd6 has become one of the most eye-catching new plastic varieties. Structure performance: MXD6 nylon material has high strength, high rigidity, high thermal deformation temperature, small thermal expansion coefficient; Dimensional stability, low water absorption rate and small size change after water absorption, mechanical strength changes less; Forming shrinkage is small, suitable for precision forming processing; Excellent coating performance, especially suitable for high temperature surface coating; Excellent barrier to oxygen, carbon dioxide and other gases. Excellent mechanical and thermal properties and high strength, high modulus and heat resistance, high barrier, excellent cooking resistance. MXD6-LGF MXD6 can be compounded with glass fiber for use in fiberglass reinforced materials containing 50-60% glass fiber for exceptional strength and stiffness. Even when filled with high glass content, its smooth, resin-rich surface produces a fibre-free high gloss surface, ideal for painting, metal-plating, or creating naturally reflective shells. 1. Suitable for high liquidity of thin wall It is a very fluid resin that can easily fill thin walls as thin as 0.5 mm thick even when the glass fiber content is as high as 60%. 2. Excellent surface finish A resin-rich perfect surface has a highly polished appearance, even with a high glass fiber content. 3. High strength and stiffness The tensile and flexural strength of MXD6 is similar to that of many cast metals and alloys with the addition of 50-60% glass fiber reinforced material. 4. Good dimensional stability At ambient temperatures, the linear expansion coefficient (CLTE) of MXD6 glass fiber composites is similar to that of many cast metals and alloys. Strong reproducibility due to low shrinkage and the ability to maintain tight tolerances (length tolerances as low as ± 0.05% if properly formed). MXD6 replaces metal to produce high-quality structural parts for automobiles, electronics and electrical appliances In automobile parts, many occasions require material products with high mechanical strength and good oil resistance, and can be used in the range of 120 ~ 160℃ for a long time. Glass fiber reinforced MXD6 heat resistant temperature up to 225℃, high rate of strength retention at high temperature, can be used in the cylinder block, cylinder head, piston, synchronous gear, etc. MXD6/PPO alloy has high temperature resistance, high strength, oil resistance, wear resistance, good dimensional stability and other properties, can be used for the vertical outer plate of the automobile body, front and rear fenders, wheel covers and almost can not use steel plate stamping forming curved parts and automobile chassis. Datasheet for reference Application fileds Production process Xiamen LFT composite plastic Co., Ltd Q. How to choose the fiber content of the product? Is the larger product suitable for higher fiber content material? A. This is not absolute. The content of glass fiber is not more is better. The suitable content is just to meet the requirements of each products. Q. Under what circumstances can long fiber replace short fiber? What are the common alternative materials? A. Traditional staple fiber materials can be replaced with long glass fiber and long carbon fiber LFT materials in the case of customers whose mechanical properties cannot be met or where higher metal substitutes are desired. For example, PP long glass fiber is often replacing nylon reinforced glass fiber, and nylon long glass fiber is replacing PPS series. Q. Does long glass fiber and long carbon fiber injection have special requirements for injection molding machines and molds? A. There are certainly requirements. Especially from the product design structure, as well as the injection molding machine screw nozzle and mold structure injection molding process must consider the requirements of long fiber.

- polyadipyl-m-benzoylamine LGF

- MXD6 long fiber glass composite

- Modified MXD6 lgf manufacturer direct sell

- MXD6 compounds long glass fiber

- MXD6-NA-LGF30 best price whole sell

- lft-g MXD6 fiber filled GF 20%-60%

Tags :

-

Xiamen LFT PLA Polylactic acid compounds long glass fiber thermoplastic resin for engineeringPLA plastic PLA is a non-natural polyester, which is considered as one of the most promising "green plastics" because of its excellent properties such as biocompatibility, biodegradability and high mechanical strength. PLA has good degradability and can be completely degraded by microorganisms. Products made of PLA can be completely degraded to CO2 and water after use, and are non-toxic and non-irritating. PLA has similar mechanical properties to polypropylene, while its gloss, clarity and processability are similar to polystyrene, and its processing temperature is lower than that of polyolefin. PLA can be processed into various packaging materials, fibers and nonwovens through injection molding, extrusion, blistering, blow molding, spinning and other general plastic processing methods, and PLA has been widely used in disposable plastic products. In addition, PLA can also be widely used in chemical, medical, pharmaceutical and 3D printing industries. It is now increasingly recognized that PLA polyesters will play a key role in solving the plastic pollution problem. PLA reinoforced plastic Glass fiber (English name: glass fiber or fiberglass) is an inorganic non-metallic material with excellent performance, the advantages of good insulation, heat resistance, good corrosion resistance, and high mechanical strength. One of the main uses of glass fiber for the reinforcement of composite materials. Long glass fiber generally refers to the length of more than 10mm glass fiber. Long Glass Fiber Reinforced PLA plastic refers to modified PLA composites containing glass fiber lengths of 10 to 25 mm, which are formed into a three-dimensional structure with glass fiber lengths greater than 3.1 mm through injection molding and other processes, and is referred to as Long Glass Fiber PLA, abbreviated as LGFPLA. fiber reinforce thermoplastic). From the material definition, LGFPLA is a kind of LFT. Generally, they are columnar particles of 12mm or 25mm in length and about 3mm in diameter. The pellets of about 12mm length are mainly used for injection molding, while the pellets of about 25mm length are mainly used for compression molding. In these pellets, the glass fiber has the same length as the pellets, and the glass fiber content can vary from 20% to 60%, and the color of the pellets can be color-matched according to customer requirements. LGF & SGF LFT has the following advantages over short fiber reinforced thermoplastic composites: - Longer fiber length, which significantly improves the mechanical properties of the products. - High specific stiffness and specific strength, good impact resistance, especially suitable for automotive parts applications. - Improved creep resistance, good dimensional stability, and high precision of part molding. - Excellent fatigue resistance. - Better stability in high temperature and humid environment. - Fibers can move relatively in the molding mold during the molding process, with little fiber damage. Details Number Color Length Fiber specification Package Sample Port of loading Delivery time PLA-NA-LGF Natural color or as customized 6-25mm 20%-60% 25kg/bag Available Xiamen Port 7-15 days after shipment Lab & factory Xiamen LFT composite plastic Co., Ltd. The rapid development of technology has led to the emergence of LFT carbon fiber composites. Long Fiber (Xiamen) New Material Technology Co., Ltd, provides professional customization service for modified reinforced long carbon fiber composites. Ltd. was founded by a veteran of the thermoplastic reinforced composite industry, focusing on the development and production of (LFT-G.LFRT,LFT) long glass/carbon fiber reinforced thermoplastic engineering plastics. The company produces long carbon fiber composites with the advantages of light weight, high strength, high impact thermal resistance, design and recycleable, green and environmental protection. Compared with traditional materials, it requires lower cost, better corrosion and chemical resistance, and better molding and processing performance, making it the golden material of the 21st century. Long Fiber (Xiamen) New Material Technology Co: Xiamen LFT composite plastic Co., Ltd. is engaged in the development and production of LFRT series of long glass fiber (LGF) and long carbon fiber (LCF) PP, PA6, PA66, PPA, PA12, TPU, PBT, PLA, PET, PPS, PEEK and other engineering plastics. Series of products can be used in the manufacture of home appliances, aerospace, automotive, military, electrical and other parts, such as gears, rollers, pulleys, drums, pump impellers, fan blades, etc. They can also be used in the manufacture of medical equipment, sporting goods, daily necessities and other fields.

- PLA reinforced plastic lgf production pla

- LFT-G PLA injection mold modified materials

- long glass fiber compounds pla resin basic

- PLA pellets of long fiber 30 made in China

- Self owing PLA polymers manufacturer direct sell

- PLA pure pellets virgin grade lft

Tags :

-

Xiamen LFT-G PLA Polylactic acid composite long carbon fiber thermoplastic resinWhat is long carbon fiber PLA? While biobased polylactic acid (PLA) thermoplastics are relatively eco-friendly and easy to recycle, composites such as carbon fibre are much stronger. Long carbon fiber reinforced PLA is an outstanding material that is strong, lightweight, has excellent layer bonding and low warpage. It has excellent layer adhesion and low warpage. Long carbon fiber PLA is stronger than other 3D-printed materials. Long carbon fiber filaments are not as strong as other 3D materials, but tougher. The increased rigidity of carbon fiber means increased structural support but reduced overall flexibility. It is slightly more brittle than regular PLA. When printed, the material is a dark glossy color that shimmers slightly under direct light. What is long carbon fiber? Long carbon fiber reinforced composites offer siginificant weight savings and provide optimum strength and stiffness properties in reinforced thermoplastics. The excellent mechanical properties of long carbon fiber reinforced composites make it an ideal replacement for metals. characteristic The fracture strain is moderate (8-10%), so the silk is not brittle, but strong toughness Very high melt strength and viscosity Good dimensional accuracy and stability Easy to handle on many platforms High attractive matte black surface Excellent impact resistance and lightness Application of long carbon fiber PLA materials Long carbon fiber PLA is an ideal material for frame, support, shell, propeller, chemical instrument and so on. Drone makers and RC enthusiasts especially like it, too. Ideal for applications requiring maximum stiffness and strength. Details Number PLA-NA-LCF30 Color Original black (can be customized) Length 12mm (can be customized) MOQ 20kg Package 20kg/bag Sample Available Delivery time 7-15 days after shipment Port of Loading Xiamen Port Exihibition We will offer you: 1. LFT & LFRT material technical parameters and leading edge design 2. Mold front design and recommendations 3. Provide technical support such as injection molding and extrusion molding

- PLA LCF original color resin made in China

- Polylactic acid filling long carbon fiber

- PLA resin lcf reinforced plastic pellets

- LFT cpmpounds pla manufacturer direct sell

- lcf reinforced material pla good price

- Thermoplastic pla lcf instead metal CF

Tags :

-

Xiamen LFT Polyamide12 filled Long Carbon Fiber composite lightweight sample availablePA12 information Long carbon chain nylon is a nylon with amide group in the main chain repeating unit of nylon molecule, and the length of methylene group between two amide groups is more than 10. We call it as long carbon chain nylon, including nylon 11, nylon 12, etc.. PA12 is nylon 12, also known as poly(dodecalactam) and poly(laurolactam), which is a kind of long carbon chain nylon. The basic raw material for polymerization is butadiene, a semi-crystalline - crystalline thermoplastic material. Nylon 12 is the most widely used long carbon chain nylon, it has most of the general properties of nylon, in addition to low water absorption, and has high dimensional stability, high temperature resistance, corrosion resistance, good toughness, easy processing and other advantages. Compared with PA11, another long carbon chain nylon material, PA12's raw material butadiene is only one-third the price of PA11's raw material castor oil, and can be used in most scenarios instead of PA11, and has wide applications in many fields such as automotive fuel hoses, air brake hoses, submarine cables, and 3D printing. Among long-chain nylon, PA12 has great advantages compared with other nylon materials, its advantages are the lowest water absorption, lowest density, low melting point, impact resistance, friction resistance, low temperature resistance, fuel resistance, good dimensional stability, good anti-noise effect, etc. PA12 has the properties of PA6, PA66 and polyolefin (PE, PP) at the same time, to achieve the combination of lightweight and physical and chemical properties, with performance It has the advantages of light weight and physical and chemical properties. PA12-LCF If the base material is compared to concrete, the fiber is like steel reinforcement, and mixing the two is like adding steel reinforcement to concrete. If there is only concrete, the castings will easily crack under external forces, but once the high-strength reinforcement is added to it and the concrete wraps it sufficiently, they will become a single unit. When the object is subjected to external forces, the rebar can withstand most of the external forces, making the structural strength of this whole very high. Carbon fiber has many excellent properties, high axial strength and modulus of carbon fiber, low density, high specific performance, no creep, resistance to ultra-high temperature in non-oxidizing environment, good fatigue resistance, specific heat and electrical conductivity between non-metal and metal, small coefficient of thermal expansion and anisotropy, good corrosion resistance, good X-ray transmittance. Good electrical and thermal conductivity, good electromagnetic shielding, etc. Compared with traditional glass fiber, carbon fiber has more than 3 times of Young's modulus; it is about 2 times of Young's modulus compared with Kevlar fiber, which is insoluble and swollen in organic solvents, acids and alkalis, and has outstanding corrosion resistance. Nylon itself is an engineering plastic with excellent performance, but moisture absorption, poor dimensional stability of products. Strength and hardness is also far from metal. In order to overcome these shortcomings, as early as before the 70s. People have used carbon fiber or other varieties of fibers for reinforcement to improve its performance. Carbon fiber reinforced nylon materials have developed rapidly in recent years, because nylon and carbon fiber are excellent performance in the field of engineering plastics materials, its compound material synthesis reflects the superiority of the two, such as strength and rigidity than unreinforced nylon is much higher, high temperature creep is small, thermal stability has improved significantly, good dimensional accuracy, wear resistance. Excellent damping, compared with glass fiber reinforced has better performance. Therefore, carbon fiber reinforced nylon (CF/PA) composites have developed rapidly in recent years. Datasheet for reference Nylon 12 has low water absorption, good low temperature resistance, good air tightness, excellent alkali and grease resistance, medium resistance to alcohols and inorganic dilute acids and aromatics, good mechanical and electrical properties, and is a self-extinguishing material. Application Suitable for the automotive, sports parts, solar energy, high-end toys and other industries. Other products you may wonder PP-LCF PA6-LCF PA66-LCF ...

- Nylon composite pellets Polymer granules

- Nylon polymer LCF manufacturer

- Modified materials Nylon PA12

- extrusion level Nylon modified

- pa lcf30 producer mess production good price

- carbone fiber reinforced pa12 pellets

Tags :

-

Xiamen LFT-G Polyamide 12 filling long glass fiber compounds high rigidity and toughnessPA12 PA12 polyamide or nylon 12 Chemical and physical properties of PA12 PA12 is a linear, semi-crystalline - crystalline thermoplastic material from butadiene. Its properties are similar to PA11, but its crystal structure is different. PA12 is a good electrical insulator and will not be affected by moisture as other polyamides. PA12 has good impact resistance mechanical and chemical stability. There are many improved varieties of PA12 in terms of plasticizing and reinforcing properties. Compared with PA6 and PA66, these materials have lower melting point and density, and have very high moisture recovery. PA12 has no resistance to strong oxidizing acids. The viscosity of PA12 depends mainly on humidity, temperature and storage time. PA12 It's very liquid. The shrinkage rate of PA12 is between 0.5% and 2%, depending on the variety of PA12 material, wall thickness and other process conditions. PA12 compounds plastic Nylon glass fiber material is a kind of composite material, adding glass fiber on the basis of the original nylon material, so that the material has the following characteristics: High temperature resistance, good dimensional stability, good toughness, good insulation, corrosion resistance, high mechanical strength. LGF & SGF comparison Compared with the short fiber, it has more excellent performance in mechanical properties. It is more suitable for large products and structural parts. It has 1-3 times higher (toughness) than short fiber, and the tensile strength (strength and rigidity) is increased by 0.5-1 times. Datasheet for reference Application ■ Power tools: cutting machine, electric saw, electric drill, Angle grinder, polishing machine, electric hammer, electric pick, hot air gun and other models; ■ Automotive industry: cooling chamber, intake manifold, frame bracket, ventilation grille, door handle, throttle body and other models; ■ Machinery industry: water pump, water valve, bearing, shaft sleeve, gear, bracket and other models; ■ Sports equipment: ski equipment, baby carriage, fitness equipment parts and other models; ■ Office equipment: seat bracket, pulley, rotating shaft, shredder gear, printer parts and other models; Certification Factory Package Why choose us

- long glass fiber polyamide12

- long fibre reinforced thermoplastics resin

- long fiber compounds nylon12 best price

- lft-g PA12 manufacturer whole sell

- PA12 granules reinforced nylon material

- Polyamide12 nylon12 plastics automotive

Tags :

-

LFT Polyamide 6.6 Manufacturer Carbon Fiber filled Compounds green materialsPolyamide, which is also known by the trade name, Nylon, has excellent heat resistant properties, especially when combined with additives and filler materials.

- Nylon PA 66 thermoplastic resinforced material

- fiber filling polymer instead of metal steel

- Sample free natural plastic new CFRP

- engineering plastic structural parts

- modified resin good price low MOQ

- Car parts application good price

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文