-

China Carbon Fiber PLA Modified CompoundsLong Fiber Reinforced PLA (LFR-PLA) is an engineering plastic that combines long glass fibers with polylactic acid (PLA) resin. PLA itself is an environmentally friendly thermoplastic, known for its biodegradability. However, it has limited mechanical properties, such as strength, toughness, and heat resistance.

- carbon reinforced PLA

- PLA green materials

- pla recycled materials

- PLA composites

- carbon fiber reinforced plastic

- china carbon fiber

Tags :

-

China Carbon Fiber Polyetheretherketone Modified CompoundsPure PEEK itself is a special engineering plastic, with radiation resistance, self-lubrication, high temperature resistance, wear resistance, fatigue resistance and other characteristics. The performance of carbon fiber reinforced PEEK material has improved in many aspects compared with pure PEEK material.view more

-

China Carbon Fiber Polyphenylene Sulfide Modified CompoundsPPS is a high-performance, tough engineering plastic with great dimensional and thermal stability, as well as a wide operating temperature range of up to 260 °C and good chemical resistance. Moreover, PPS, like most other thermoplastics, is an electrical insulator. Its ability to be used at high temperatures coupled with its thermal stability makes PPS great for applications such as semiconductor components in machinery, bearings, and valve seats.

- plastic granules price per kg

- long fibre reinforced thermoplastics

- PPS Plastic

- pps melting point

- Injection molding pps

- Engineering plastic

Tags :

-

China Carbon Fiber Nylon 1,2 Modified CompoundsThis material combines the excellent toughness, low moisture absorption, and chemical resistance of PA12 with the superior strength, stiffness, and fatigue resistance provided by long carbon fibers. It is designed for advanced lightweight structural applications.

- PA12 Resin

- Nylon CFRTP

- Nylon polymer

- PA12 VS PA6

- thermoplastic carbon fiber composite

- composites for ev battery

Tags :

-

China Carbon Fiber Nylon 6,6 Modified CompoundsThe carbon fiber reinforcement improves strength, impact resistance, and overall structural integrity, making it ideal for critical applications. With excellent thermal stability and chemical resistance, it's well-suited for high-temperature and harsh environments.

- Reinforced PA66 plastic

- Lightweight structural materials

- High-strength PA66 thermoplastic

- CFRP

- difference between pa6 and pa66

- nylon 66 density

Tags :

-

Long Carbon Fiber Nylon 6 Modified CompoundsCompared to short fiber counterparts, this composite offers superior load-bearing capability and long-term durability under dynamic stress conditions. Its balanced properties make it ideal for structural components in the automotive, aerospace, power tool, and industrial sectors, where lightweight yet robust materials are essential.

- carbon fiber reinforced

- Nylon composites

- Pa66 cf

- Natural PA6

- plastic for automotive parts

- Engineering thermoplastics supplier

Tags :

-

Long Carbon Fiber Copolymer Polypropylene Modified CompoundsCarbon fiber reinforced composite (CFRP) is composed of carbon fiber as a reinforcement material and resin as a matrix material, and early carbon fiber composite materials are mainly used in the military field. With the improvement of material properties, molding process and price cost, carbon fiber composite materials are more and more used in general industry and sports and leisure fields.

- pp 30 cf

- carbon fiber resistance

- difference between copolymer and homopolymer

- long-fiber thermoplastic composite solutions

- carbon thermoplastic

- automotive thermoplastic composites

Tags :

-

Long Carbon Fiber Polypropylene Modified CompoundsPolypropylene, also known as PP or polypropene, is a polyolefin or saturated polymer. It is a low-density thermoplastic with good resistance to heat. Other characteristics of PP include: chemical resistance, elasticity, toughness, fatigue resistance, and electrical insulation capability.view more

-

Impact Resistant Long Fiber Polyamide Nylon MXD 6 Lightweight and ToughMXD6 is a high-performance engineering plastic known for its exceptional gas barrier, mechanical strength, and dimensional stability. It fills a unique niche between transparent barrier resins and high-rigidity nylons. Its versatility makes it ideal for packaging, automotive, electronics, and industrial applications.

- Nylon MXD 6

- Fiber reinforced MXD 6

- Low moisture absorption nylon

- High-performance nylon MXD6

- High stiffness MXD6 polymer

- MXD6 injection molding grade

Tags :

-

Impact Resistant Long Fiber HDPE Lightweight and ToughLong Glass Fiber Reinforced High-Density Polyethylene (HDPE-LGF) is a high-performance thermoplastic composite made by reinforcing HDPE resin with long glass fibers using a continuous fiber impregnation process. Compared to short glass fiber filled HDPE, this material offers significantly enhanced mechanical properties, fatigue resistance, creep resistance, and structural stability, while retaining HDPE’s excellent chemical resistance and processability.

- HDPE glass fiber

- HDPE for structural applications

- Durable thermoplastic for heavy-duty use

- PE GF

- hdpe glass

- Reinforced HDPE resin

Tags :

-

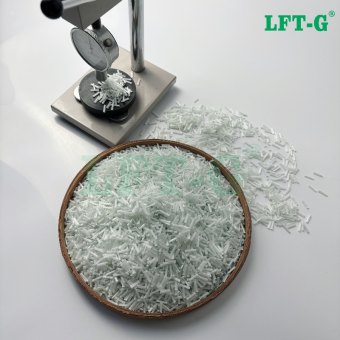

High Performance Long Fiber PLA Lightweight Metal Replacement SolutionLong Fiber Reinforced PLA (LFR-PLA) is an engineering plastic that combines long glass fibers with polylactic acid (PLA) resin. PLA itself is an environmentally friendly thermoplastic, known for its biodegradability. However, it has limited mechanical properties, such as strength, toughness, and heat resistance. By incorporating long glass fibers, the performance of PLA is significantly improved, making it suitable for demanding applications.

- PLA Green materials

- PLA recycled plastics

- composite materials in renewable energy market

- glass filled PLA filament

- long fiber filling materials

- Polylactic acid

Tags :

-

High Performance Long Fiber ABS Lightweight Metal Replacement SolutionGlass fiber reinforced ABS modified plastics have many advantages, including excellent strength and stiffness, excellent heat resistance, good chemical resistance, low water absorption, good electrical insulation and stable performance. These advantages make it have a wide range of application prospects in many fields, and can meet the needs of different industries for high-performance materials.

- Reinforced ABS plastic

- High-performance plastic compounds

- Automotive ABS plastic parts

- Industrial ABS components

- ABS GF

- long fiber composites

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文