item no.:

PA66-NA-LCFPayment:

Discussedproduct origin:

ChinaColor:

Natural color or Customizedshipping port:

XiamenLead Time:

2-10 working days

Product Details

- What is Glass Filled Nylon?

A form of technical plastic called Glass Filled Nylon is made of Nylon compounds combined with glass fibers. The Nylon material's strength, stiffness, heat resistance, and dimensional stability are all enhanced by the reinforcement provided by the glass fibers. Glass reinforced Nylon or glass fiber reinforced Nylon are other names for Glass Filled Nylon.

A class of polymers known as engineering plastics has better mechanical and thermal characteristics than regular plastics. They are used in goods for the automotive, electrical, industrial, and domestic markets that need great performance and durability.

Engineering plastics such as Nylon are formed of synthetic polymers known as polyamides. Nylon is strong, resilient to impact, abrasion, and chemicals. However, Nylon has several downsides, including a lack of rigidity, a high moisture absorption rate, poor heat resistance, and a high thermal expansion rate.

The characteristics of the material may be considerably improved by mixing glass fibers with Nylon compounds. Glass fibers act as reinforcement and slow down the movement of the polymer chains to boost the material's strength and stiffness. The glass fibers increase the material's dimensional stability and capacity to withstand heat by minimizing thermal expansion and creep deformation.

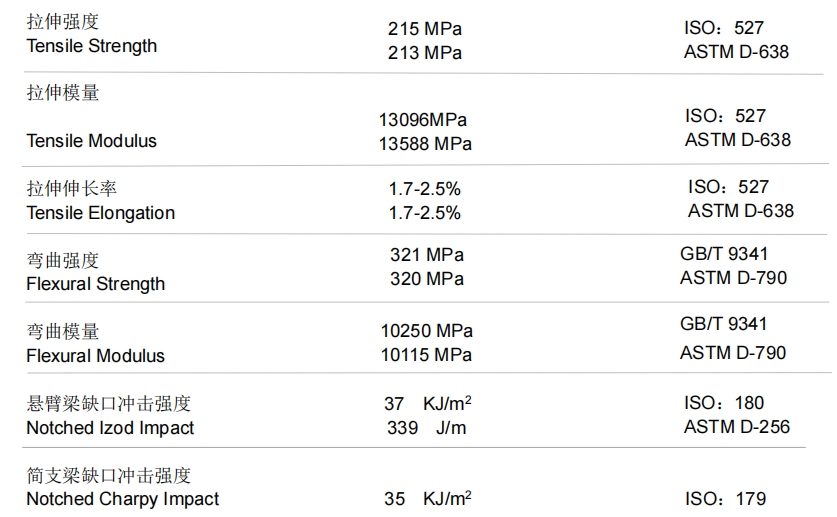

Polyamide 66 with 40% LGF

- What Are the Applications of Polyamide 66 Long Fiber Reinforcement?

Long glass fiber reinforced nylon 66 can be widely used in building materials, aerospace, electronic devices, furniture and other fields, especially in the automotive industry application market.

Company Advantages

Excellent quality. As replacement of metal and steel.

Own-factory. 500-800 tons of production per month.

Customization. From length to color or additives.

Self laboratory. Provide TDS and COA for every batch.

Fast shipping. Fast shipping to all capital cities or ports.

Favorable price. Free to get price.

Experienced team. With over 20 years experience expert team to provide assistance.

Full service. Through product discussion, performance analysis, composite selection, composite pellet production, after-sales tracking to injection molding techniques.

FAQ

Q. The product is easy to brittle, so changing to use long fiber reinforced thermoplastic materials can solve this problem?

A: The overall mechanical properties must be improved. The characteristics of long glass fiber and long carbon fiber are the advantages in mechanical properties. It has 1-3 times higher (toughness) than short fiber , and the tensile strength(strength and rigidity) is increased by 0.5-1 times.

Q. What are the differences and advantages of long fiber materials and short fibers?

A:Long-fiber reinforced composites show excellent mechanical properties compared to short fibers and are more suitable for applications requiring high strength. The impact performance of long fiber composites is 1-3 times higher than that of short fibers, tensile strength is more than 50% higher, and mechanical properties are 50-80% higher.

Q. How to choose the reinforcement method and length of the material when using long fiber reinforced thermoplastic material?

A: The selection of materials depend on the requirements of the products. It is necessary to assess how much the content is enhanced and how much length is more appropriate, which are depending on the performance requirements of the products.

Talk to an expert now

Email: sales02@lfrtplastic.com

WhatsApp: +86 139 5009 5727