-

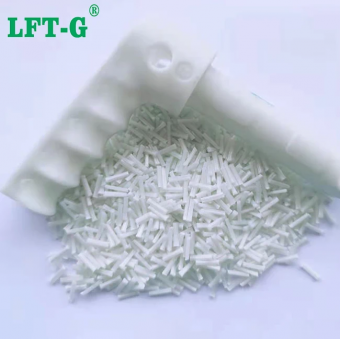

Newly developed yellow PP long fiber modified particles for refrigerator partsPP filling long glass fiber polypropylene lgf reinforced thermoplastic pellets.

- Modified PP long fiber material

- PP modified materials for automotive parts

- Lightweight PP modified particles

- Long glass fiber 20-60%PP particles

- Polypropylene Long fiber polymer

- LFT PP glass fiber pellets

Tags :

-

pp long glass fiber enhance granules LFT composite granulespp roving glass fiber enhance granules LFT composite granules for injection mold

- PP long fiber material

- PP homopolymer lgf pellets

- Longs CPP LFT pellets

- Roving glass fiber polypropylene

- Polypropylene roving glass fiber enhance pellet

- LFT PP roving glass fiber composite

Tags :

-

LFT PP LGF60 modified plastic for fan support partsLGF40 PP modified plastic for fan support parts

- Long fiber materials

- Long glass fiber reinforced polypropylene

- Flame retardant polypropylene pellet

- LFT PP LGF60

- LGF polypropylene glass fiber 60%

- LFT Comopolyer PP GF60 granules

Tags :

-

LFT Performance PP LGF 50 Composite Plastic 12mm Length For Washing Machine PartsLGF 50 PP Modified Plastic For Washing Machine Parts

- Glass fiber reinforced thermoplastics

- PP LGF 50

- Polypropylene long fiber composite

- Polymer reinforced composite

Tags :

-

LFT PP LGF 40 GF40 Polypropylene Composite Plastic Long Glass Fiber PolymerPP Long Glass Fiber Reinforced Thermoplastic Granules For Injection Moldview more

-

HDPE LFT-G filling Long Glass Fiber 20%-60% natural grade high performance sample availableHDPE introduce High density polyethylene (HDPE) is a white powder or granular product. Non-toxic, tasteless, crystallinity is 80% ~ 90%, softening point is 125 ~ 135℃, the use of temperature can reach 100℃; The hardness, tensile strength and creep property are better than low density polyethylene. Good wear resistance, electrical insulation, toughness and cold resistance; Good chemical stability, at room temperature, insoluble in any organic solvent, acid, alkali and all kinds of salt corrosion resistance; Thin film to water vapor and air permeability is small, low water absorption; Poor aging resistance, environmental stress cracking resistance is not as good as low density polyethylene, especially thermal oxidation will reduce its performance, so the resin must be added in antioxidants and ultraviolet absorbent to improve this deficiency. High density polyethylene film under the condition of stress thermal deformation temperature is low, should pay attention to the application. Long Glass Fiber filling High density polyethylene (HDPE)/ glass fiber (LGF) composites were prepared by twin-screw extrusion mechanism, and the mechanical properties and non-isothermal crystallization behavior of HDPE/LGF composites were studied. The results show that the impact strength of the composite can be improved by MAH-g-POE, and the interface bond between the glass fiber and HDPE is good. The Avrami index (n) of the composite does not change with the cooling rate. The effects of HDPE on the flow properties of PP and its mechanical properties, and the effects of the flow properties of PP/HDPE blends on the mechanical properties of LGF/PP/HDPE composites were studied. The results show that HDPE can not only improve the impact performance of PP, but also improve the liquidity of PP. The mechanical properties of LGF/PP/HDPE composites, such as tensile strength and bending strength, are mainly affected by the flow properties of the matrix, but have little effect on the mechanical properties of the matrix itself. Datasheet Tested by own lab, for your reference only. Application cases Package and Warehouse Self-owned factory Exhibitions and customers Frequently asked questions 1. Under what circumstances can long fiber replace short fiber? What are the common alternative materials? A: Traditional staple fiber materials can be replaced with long glass fiber and long carbon fiber LFT materials in the case of customers whose mechanical properties cannot be met or where higher metal substitutes are desired. For example, PP long glass fiber is often replacing nylon reinforced glass fiber, and nylon long glass fiber is replacing PPS series. 2. How to choose the fiber content of the product? Is the larger product suitable for higher content material? A: This is not absolute. The content of glass fiber is not more is better. The suitable content is just to meet the requirements of each products. 3. If want to increase the anti-aging properties of the product, is it possible to add anti-UV agent to the material? A: You can choose some materials which are better resistant to aging, and then add some antioxidants and UV absorbers to the materials, to improve the aging resistance of the products.

- HDPE filling lgf

- High Density Polyethylene raw material

- Long glass fiber filling plastic

- Granular plastic HDPE

- Reinforced materials HDPE

- long fiber material

Tags :

-

LFT Long Fiber Reinforced Nylon 66 High Strength CompoundsLFT long glass fiber reinforced PA66 material offers exceptional strength, impact resistance, and dimensional stability. With its superior mechanical properties, it is ideal for high-performance applications in automotive, electronics, and industrial components, providing durability and long-term reliability.

- Advanced Reinforced Thermoplastics

- Long Fiber Reinforced Polymers (LFRP)

- Long Fiber Composite Materials for Power Tools

- Injection Molding Long Fiber Materials

- PP/PA Reinforced Composite Materials

- Durable Composite Materials for Electronics

Tags :

-

LFT Long Fiber Reinforced Nylon 12 High Performance CompoundsPA 12 (also known as Nylon 12) is a good general-use plastic with broad additive applications and is known for its toughness, tensile strength, impact strength and ability to flex without fracture. PA 12 has long been used by injection molders due to these mechanical properties. If you’re considering converting metal parts to plastic, PA12 will be a good choice.

- High Performance PA12 Materials

- Lightweight PA12 Glass Fiber Composite

- Advanced PA12 Long Fiber Materials for Manufacturing

- PA12 Fiber Reinforced Thermoplastics

- PA12 Composite Materials for Electronics

- PA12 Composite Materials Supplier

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文