item no.:

PEEK-NA-LCFPayment:

Discussedproduct origin:

ChinaColor:

Natural color or Customizedshipping port:

XiamenLead Time:

2-10 working days

Polyether Ether Ketone (PEEK)

PEEK is a versatile molding resin ideal for applications requiring sterilized equipment or containers. It is highly resistant to chemicals and heat and capable of resisting submersion in liquids long-term. It also can generally be subjected to harsh operational environments. The mechanical properties of PEEK allow it to be used as reinforcement material in various scenarios.

Advantages of Polyether Ether Ketone (PEEK)

PEEK is fatigue and stress-resistant.

PEEK is resistant to high-pressure water and steam.

PEEK has high chemical resistance.

PEEK can be subjected to sterilization (like in autoclaving).

PEEK is easy to manufacture.

PEEK has very low emissions when exposed to flame.

PEEK Information

At room temperature, the tensile strength of carbon fiber modified PEEK material is doubled compared with that of non-enhanced, and it is tripled at 150℃. At the same time, the enhanced composite material has also been greatly improved in terms of impact strength, bending strength and modulus, and the elongation has been sharply reduced, and the thermal deformation temperature can exceed 300℃.

The impact energy absorption rate of the composite directly affects the performance of the composite under impact, and the carbon fiber reinforced peek composite shows a specific energy absorption capacity of up to 180kJ/kg.

Carbon fiber modified peek material has been widely used in aerospace, automobile manufacturing, electronics and electrical, medical and food processing fields.

FAQ

*What processes are LFT materials suitable for?

LFT material is mainly suitable for injection molding, as well as partial extrusion. The requirements for injection molding machines are mainly reflected in the nozzle.

*Why are your products so long? Why does the material I used before, filled with glass fiber, look different than this?

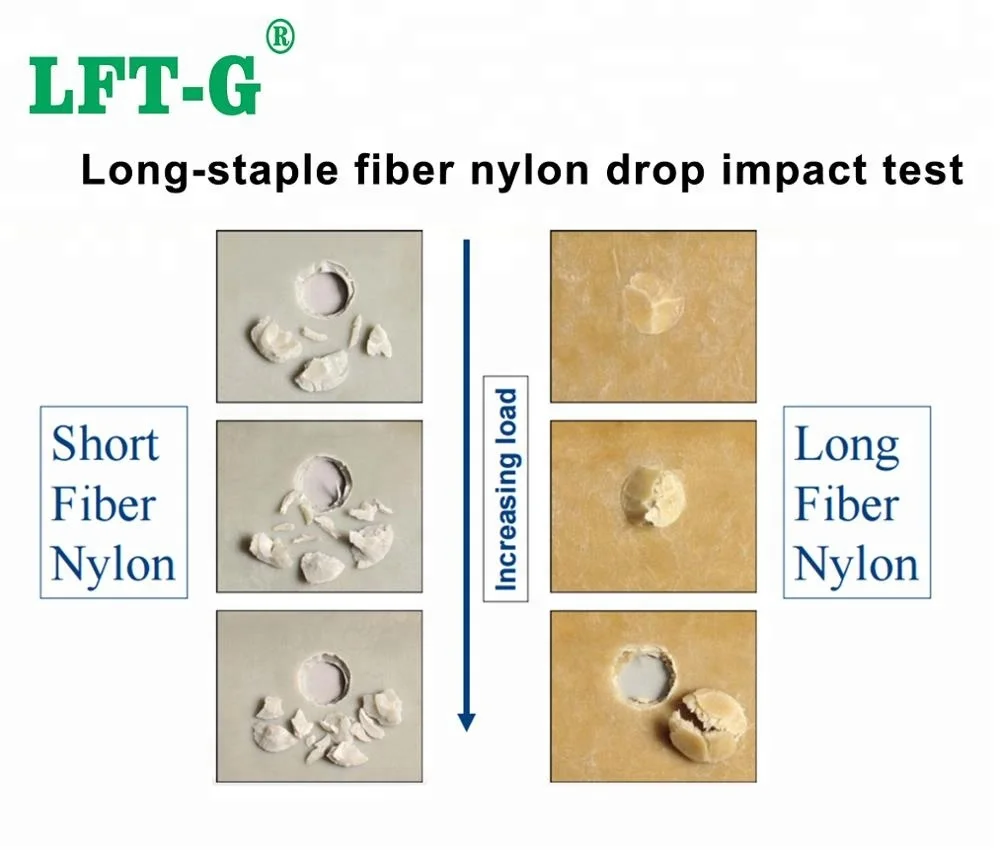

Although long fiber modified materials (LFT) and short fiber modified materials (SFT) are through the combination of fiber and resin to produce higher properties of the complex. However, the two materials are different from the production process, internal structure, appearance, performance, application and so on.

Production process: The fiber of SFT is chopped and mixed with resin, and the production process of LFT is melt impregnation.

Internal structure: The fibers inside SFT particles are short and disordered, while the fibers inside LGF are neatly arranged and longer.

Appearance: The length of SFT is usually less than 3 mm, and the length of LFT is 5-24mm.

Performance: LFT impact performance than SFT increased 1-3 times, tensile strength increased by more than 50%, mechanical properties improved by 50-80%.

Application: LFT is more suitable for use in products with high strength requirements, as load-bearing parts and structural parts.

*What is your MOQ?

MOQ is 25kg

*Do you support custom service?

Color: Please let us know which Pantone color you want to customize

Length: Lengtjh between 5mm-24mm can be customized. If there are no special requirements, the length of the plastic particles is 10-12 mm.

Our custom service is free, but the MOQ is 500kg.

*Where is your factory?

At present, our company headquarters and factory are in Xiamen, China.

We also have several offices in other provinces in China, and an exclusive agent in Turkey.