item no.:

PA66-NA-LCFPayment:

Discussedproduct origin:

ChinaColor:

Natural color or Customizedshipping port:

XiamenLead Time:

2-10 working days

Nylon 66, also written as nylon 6-6, nylon 6,6, or nylon 6/6, is a more crystalline version of nylon 6. It is also referred to as polyamide 66 or PA 66.

It has improved mechanical properties due to its more ordered molecular structure. Nylon 66 material for machining has improved temperature resistance and lower rates of water absorption when compared to standard nylon 6.

Typical applications include wear pads, guide wheels, and slide bearings.

What Are the Applications of Polyamide Long Fiber Reinforcement?

1. Engineering Plastics

Engineering plastics are broadly defined as plastics that have better-performing properties than more widely used plastics. In the case of polyamides, these properties are good wear resistance, high strength, chemical resistance, and impact resistance. These better properties mean polyamides are used for helmets, bearings, supports, piping, and protective equipment.

2. Automotive Industry

Polyamides are used in the automotive industry for their light weight, low cost, and good mechanical properties. Specific automotive applications include engine air intakes, car gate, engine covers, pulley tensioners, fuel lines, fuel pumps, lights, and vehicle trim.

3. Electrical and Electronics

For a long time, polyamides have been the material of choice for electrical connectors. This is because electrical connectors, as well as other non-conductive electrical parts, require high heat resistance which polyamide can offer. Polyamide is also chosen due to its low cost, easy formability, high strength, and electrical insulation properties.

What Is the Color of Polyamide?

Polyamides can come in various colors including: yellow, white, and light brown. However, polyamide fibers can be dyed to any color, and solid polyamides can be surface finished with a wide variety of paint colors.

FAQ

*What processes are LFT materials suitable for?

LFT material is mainly suitable for injection molding, as well as partial extrusion. The requirements for injection molding machines are mainly reflected in the nozzle.

*Why are your products so long? Why does the material I used before, filled with glass fiber, look different than this?

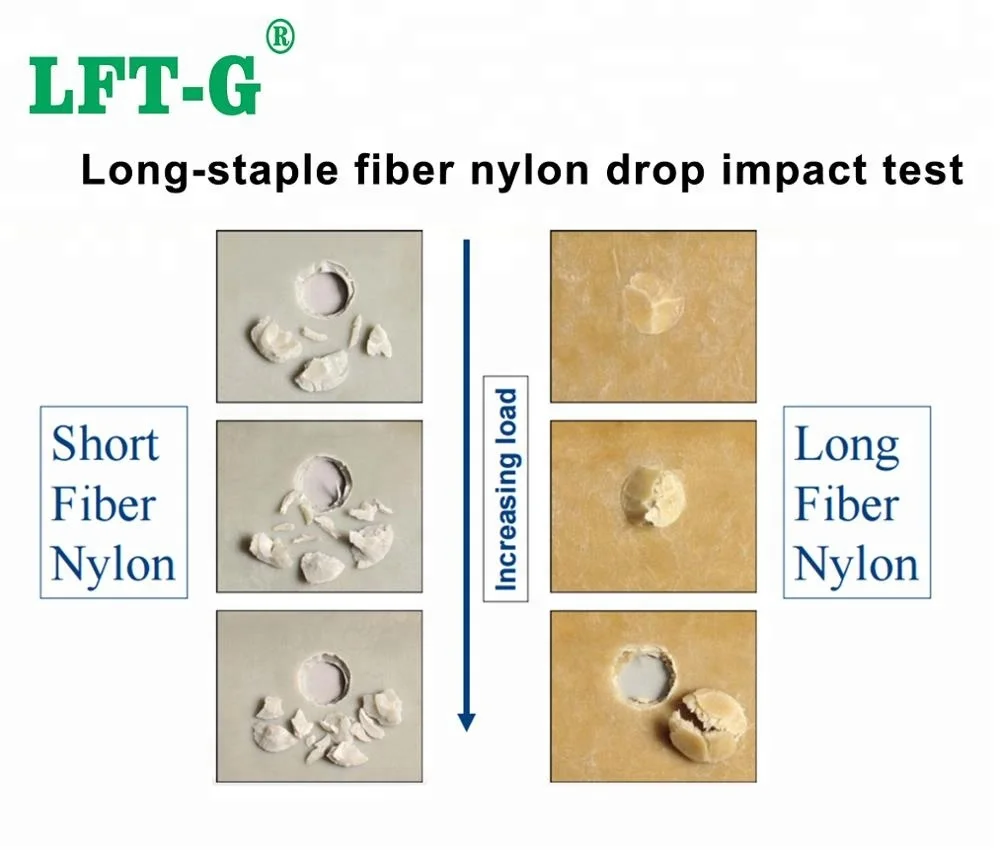

Although long fiber modified materials (LFT) and short fiber modified materials (SFT) are through the combination of fiber and resin to produce higher properties of the complex. However, the two materials are different from the production process, internal structure, appearance, performance, application and so on.

Production process: The fiber of SFT is chopped and mixed with resin, and the production process of LFT is melt impregnation.

Internal structure: The fibers inside SFT particles are short and disordered, while the fibers inside LGF are neatly arranged and longer.

Appearance: The length of SFT is usually less than 3 mm, and the length of LFT is 5-24mm.

Performance: LFT impact performance than SFT increased 1-3 times, tensile strength increased by more than 50%, mechanical properties improved by 50-80%.

Application: LFT is more suitable for use in products with high strength requirements, as load-bearing parts and structural parts.

*What is your MOQ?

MOQ is 25kg

*Do you support custom service?

Color: Please let us know which Pantone color you want to customize

Length: Lengtjh between 5mm-24mm can be customized. If there are no special requirements, the length of the plastic particles is 10-12 mm.

Our custom service is free, but the MOQ is 500kg.

*Where is your factory?

At present, our company headquarters and factory are in Xiamen, China.

We also have several offices in other provinces in China, and an exclusive agent in Turkey.