item no.:

PA12-NA-LCFPayment:

Discussedproduct origin:

ChinaColor:

Natural color or Customizedshipping port:

XiamenLead Time:

2-10 working days

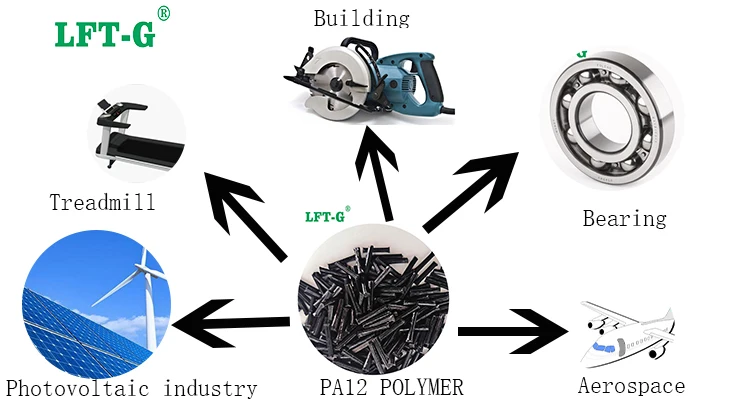

PA 12 (also known as Nylon 12) is a good general-use plastic with broad additive applications and is known for its toughness, tensile strength, impact strength and ability to flex without fracture. PA 12 has long been used by injection molders due to these mechanical properties. If you’re considering converting metal parts to plastic, PA12 will be a good choice.

PA12+CF is made using a specialty Nylon 12 [PA12] and high-modulus carbon fiber. This material offers an excellent combination of performance and lightweight. PA12 absorbs much less moisture than PA6-based materials and has superior retention of mechanical properties after exposure to humid environments.

Ideal for any applications which require light weight and rigidity.

Carbon fiber reinforced parts, designed to use less material and save weight, is extremely popular in aerospace, civil engineering, the military, and motorsports.

Key benefits of PA12+CF

PA12-LCF has many advantages that make it an attractive material for a variety of applications. Some of the key benefits include (using 30%LCF content as an example) :

High durability and hardness: the tensile strength of PA12-LCF is 241MPa, and its tensile modulus is 21973 MPa, which is much higher than that of pure nylon 12 (50 MPa and 1700 MPa, respectively). The bending strength of PA12-LCF is also 350 MPa and its bending modulus is 16,898 MPa, which is also higher than that of pure nylon 12 (80 MPa and 2000 MPa, respectively). These characteristics make PA12-LCF excellent in applications requiring high mechanical properties and strength.

Excellent heat resistance: PA12GF20 has a thermal deformation temperature (HDT) of 204°C (at 0.45 MPa), which is higher than pure nylon 12 (150°C at 0.45 MPa). This means that PA12-LCF can maintain its shape at higher temperatures without deforming or losing its performance.

Good chemical resistance: PA12-LCF is resistant to different types of chemicals such as oils, fats, fuels, solvents, acids, bases and salts. It also has the ability to resist hydrolysis, that is, it is not decomposed by water or moisture. This makes PA12-LCF suitable for applications in contact with harsh environments or liquids.

Good electrical conductivity: This makes PA12GF20 suitable for applications where electrical conductivity is required.

Good processing properties: PA12-LCF can be easily processed by different methods, such as injection molding, extrusion molding, 3D printing. PA12-LCF has a low viscosity and a wide processing window, which means that it can be injected at low temperatures and low pressures, while the processing cycle time is fast. In addition, PA12-LCF also has good fluidity and formability, which means that it is able to fill complex molds and produce parts with high precision and surface quality.

FAQ

*What processes are LFT materials suitable for?

LFT material is mainly suitable for injection molding, as well as partial extrusion. The requirements for injection molding machines are mainly reflected in the nozzle.

*Why are your products so long? Why does the material I used before, filled with glass fiber, look different than this?

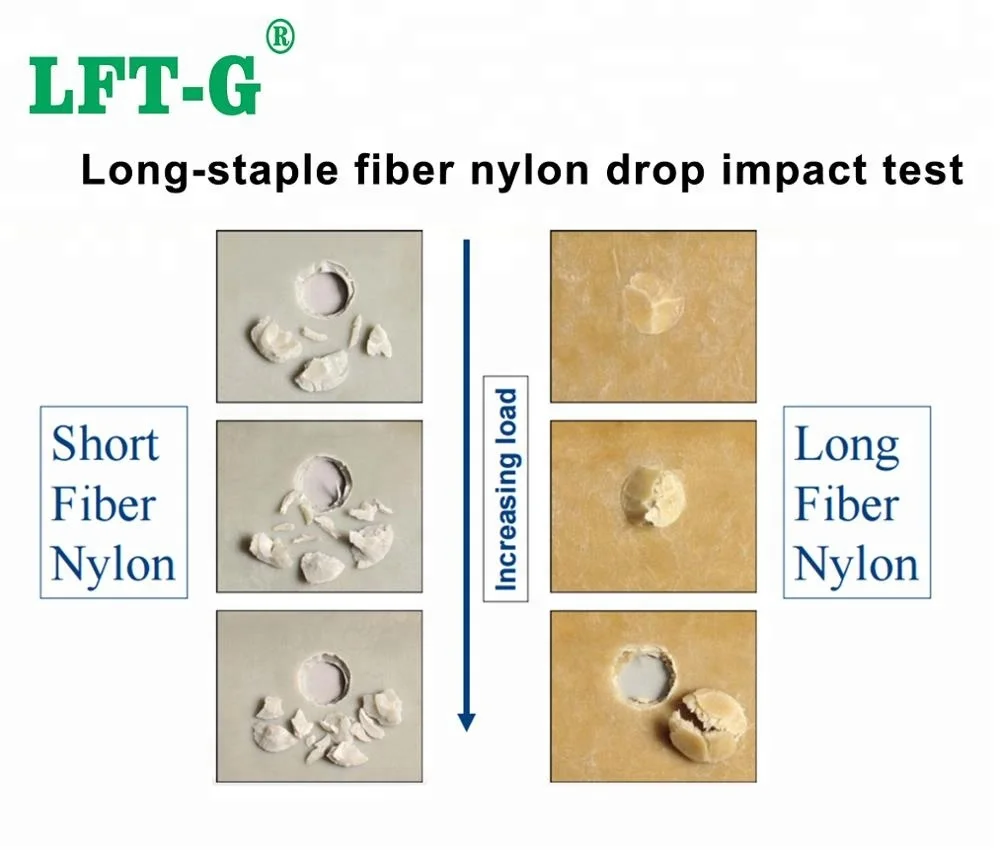

Although long fiber modified materials (LFT) and short fiber modified materials (SFT) are through the combination of fiber and resin to produce higher properties of the complex. However, the two materials are different from the production process, internal structure, appearance, performance, application and so on.

Production process: The fiber of SFT is chopped and mixed with resin, and the production process of LFT is melt impregnation.

Internal structure: The fibers inside SFT particles are short and disordered, while the fibers inside LGF are neatly arranged and longer.

Appearance: The length of SFT is usually less than 3 mm, and the length of LFT is 5-24mm.

Performance: LFT impact performance than SFT increased 1-3 times, tensile strength increased by more than 50%, mechanical properties improved by 50-80%.

Application: LFT is more suitable for use in products with high strength requirements, as load-bearing parts and structural parts.

*What is your MOQ?

MOQ is 25kg

*Do you support custom service?

Color: Please let us know which Pantone color you want to customize

Length: Lengtjh between 5mm-24mm can be customized. If there are no special requirements, the length of the plastic particles is 10-12 mm.

Our custom service is free, but the MOQ is 500kg.

*Where is your factory?

At present, our company headquarters and factory are in Xiamen, China.

We also have several offices in other provinces in China, and an exclusive agent in Turkey.