item no.:

PA12-NA-LCFPayment:

Discussedproduct origin:

ChinaColor:

Natural color or Customizedshipping port:

XiamenLead Time:

2-10 working daysThe properties of PA12-LCF

PA12-LCF has many advantages that make it an attractive material for a variety of applications. Some of the key benefits include (using 30%LCF content as an example) :

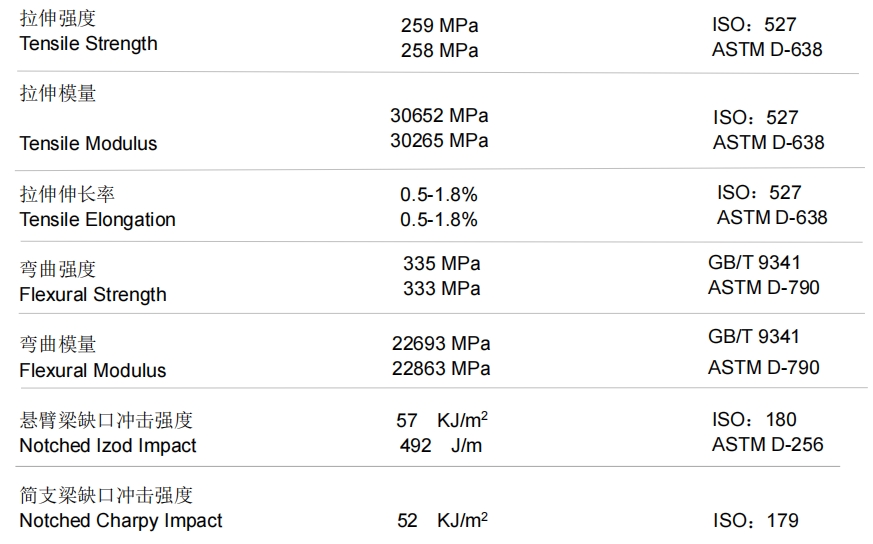

High durability and hardness: the tensile strength of PA12-LCF is 241MPa, and its tensile modulus is 21973 MPa, which is much higher than that of pure nylon 12 (50 MPa and 1700 MPa, respectively). The bending strength of PA12-LCF is also 350 MPa and its bending modulus is 16,898 MPa, which is also higher than that of pure nylon 12 (80 MPa and 2000 MPa, respectively). These characteristics make PA12-LCF excellent in applications requiring high mechanical properties and strength.

Excellent heat resistance: PA12-CF20 has a thermal deformation temperature (HDT) of 204°C (at 0.45 MPa), which is higher than pure nylon 12 (150°C at 0.45 MPa). This means that PA12-LCF can maintain its shape at higher temperatures without deforming or losing its performance.

Good chemical resistance: PA12-LCF is resistant to different types of chemicals such as oils, fats, fuels, solvents, acids, bases and salts. It also has the ability to resist hydrolysis, that is, it is not decomposed by water or moisture. This makes PA12-LCF suitable for applications in contact with harsh environments or liquids.

Good electrical conductivity: This makes PA12-CF20 suitable for applications where electrical conductivity is required.

Good processing properties: PA12-LCF can be easily processed by different methods, such as injection molding, extrusion molding, 3D printing. PA12-LCF has a low viscosity and a wide processing window, which means that it can be injected at low temperatures and low pressures, while the processing cycle time is fast. In addition, PA12-LCF also has good fluidity and formability, which means that it is able to fill complex molds and produce parts with high precision and surface quality.

Polyamide 12 with 50% LCF

Applications

Ideal for any applications which require light weight and rigidity.

Carbon fiber reinforced parts, designed to use less material and save weight, is extremely popular in aerospace, civil engineering, the military, and motorsports.

Company Advantages

Excellent quality. As replacement of metal and steel.

Own-factory. 500-800 tons of production per month.

Customization. From length to color or additives.

Self laboratory. Provide TDS and COA for every batch.

Fast shipping. Fast shipping to all capital cities or ports.

Favorable price. Free to get price.

Experienced team. With over 20 years experience expert team to provide assistance.

Full service. Through product discussion, performance analysis, composite selection, composite pellet production, after-sales tracking to injection molding techniques.

FAQ

Q. Are Engineering Plastics Strong?

A: Yes, engineering plastics are strong. They are specifically formulated to have high tensile strength and impact strength compared to standard commodity plastics such as polypropylene or polyethylene.

Q. What Is the Color of Polyamide?

A:Polyamides can come in various colors including: yellow, white, and light brown. However, polyamide fibers can be dyed to any color, and solid polyamides can be surface finished with a wide variety of paint colors.

Q. What Are the Physical Properties of Polyamide?

A: The most notable physical property of polyamide is its excellent wear resistance due to its low coefficient of friction created by its self-lubricating properties. Below is a list of other physical polyamide properties:

Low density.

Temperature resistance.

Good impact resistance.

High strength.

Flexibility.

Talk to an expert now

Email: sales02@lfrtplastic.com

WhatsApp: +86 139 5009 5727