Product Details

- What is the Impact of Carbon-Filled Polypropylene?

High strength-to-weight ratio

Superb load carrying ability

Exceptional long-term creep resistance

Cyclical fatigue endurance

Resistant to deformation and crack propagation

Outstanding dimensional stability

Performance maintained at low and elevated temperatures

Low coefficient of thermal expansion

Copolymer PP with 50% LGF

- Production Process

1. Through the physical and chemical treatment of the original carbon fiber, it removes impurities, improves surface activity, and provides the mechanical properties and durability of pre-soaked materials.

2. Add resin, additives, etc., form a unique formula. Improve flowability, hardness, temperature stability.

3. The pre-treated carbon fiber is placed on the machine, and the resin is evenly covered on its surface.

4. Use the machine to solidify the material, and the fiber and resin are both sufficiently bonded.

5. According to the requirements of the product, cutting particles.

Company Advantages

Excellent quality. As replacement of metal and steel.

Own-factory. 500-800 tons of production per month.

Customization. From length to color or additives.

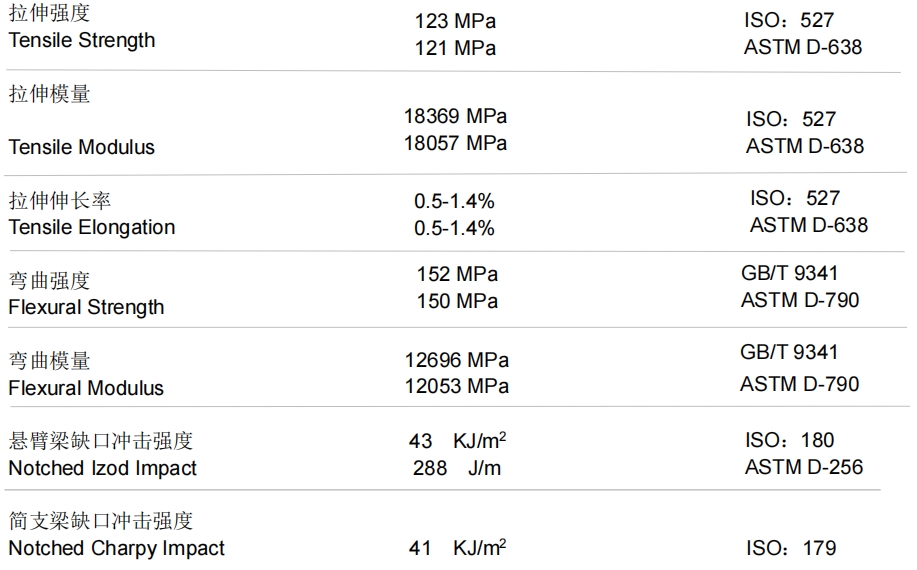

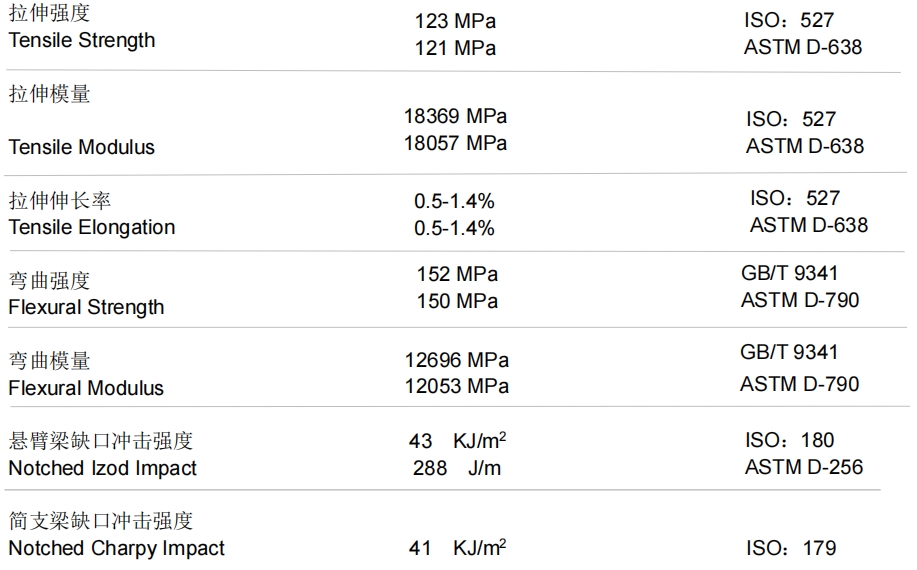

Self laboratory. Provide TDS and COA for every batch.

Fast shipping. Fast shipping to all capital cities or ports.

Favorable price. Free to get price.

Experienced team. With over 20 years experience expert team to provide assistance.

Full service. Through product discussion, performance analysis, composite selection, composite pellet production, after-sales tracking to injection molding techniques.

FAQ

Q. The product is easy to brittle, so changing to use long fiber reinforced thermoplastic materials can solve this problem?

A: The overall mechanical properties must be improved. The characteristics of long glass fiber and long carbon fiber are the advantages in mechanical properties. It has 1-3 times higher (toughness) than short fiber , and the tensile strength(strength and rigidity) is increased by 0.5-1 times.

Q. What are the differences and advantages of long fiber materials and short fibers?

A:Long-fiber reinforced composites show excellent mechanical properties compared to short fibers and are more suitable for applications requiring high strength. The impact performance of long fiber composites is 1-3 times higher than that of short fibers, tensile strength is more than 50% higher, and mechanical properties are 50-80% higher.

Q. How to choose the reinforcement method and length of the material when using long fiber reinforced thermoplastic material?

A: The selection of materials depend on the requirements of the products. It is necessary to assess how much the content is enhanced and how much length is more appropriate, which are depending on the performance requirements of the products.

Q. Can products with appearance requirements be made of long-fiber materials?

A: The main feature of LFT-G thermoplastic long glass fiber and long carbon fiber is to show the mechanical properties. If the customer has bright or other requirements for the appearance of the product, it needs to be evaluated in combination with specific products.

Talk to an expert now

Email: sales02@lfrtplastic.com

WhatsApp: +86 139 5009 5727

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文