item no.:

PP-NA-LGFPayment:

Discussedproduct origin:

ChinaColor:

Natural color or Customizedshipping port:

XiamenLead Time:

2-10 working days

Product Details

- What is Glass-Filled Polypropylene?

First of all, what is polypropylene plastic? Polypropylene plastic (PP plastic for short, chemical formula (C3H6)n) is a form of polymer resin created from the polymerization of propylene. PP plastic beads are usually colorless, odorless, tasteless, and especially non-toxic to health. With outstanding advantages such as cheap price, high elasticity, good chemical resistance and good electrical and thermal insulation, PP plastic is popular and used to produce household items such as food storage boxes, or other heavy industrial products such as electronic components.

In the manufacturing industry, in order to match some output products that require higher quality than usual, manufacturers will mix into PP plastic with glass fiber or glass beads. These two different forms of glass enhancement are inherently tough and durable, so when mixed, glass-filled polypropylene materials become lighter and stronger.

Copolymer PP with 50% LGF

- What is the application of Glass-Filled Polypropylene?

PP long glass fiber reinforced materials are widely used across various industries due to their excellent mechanical properties and versatility. In the automotive industry, they are commonly used for manufacturing lightweight, high-strength components such as bumpers, door panels, and engine covers, improving fuel efficiency and overall vehicle performance. In electronics, these materials are utilized for durable housings and structural components that require impact resistance and dimensional stability. They are also used in industrial applications, including power tools, home appliances, and electrical parts, where robustness and long-term durability are essential. Additionally, they are increasingly being used in construction for reinforcing composite materials that require high load-bearing capacity and resistance to wear and tear.

Company Advantages

Excellent quality. As replacement of metal and steel.

Own-factory. 500-800 tons of production per month.

Customization. From length to color or additives.

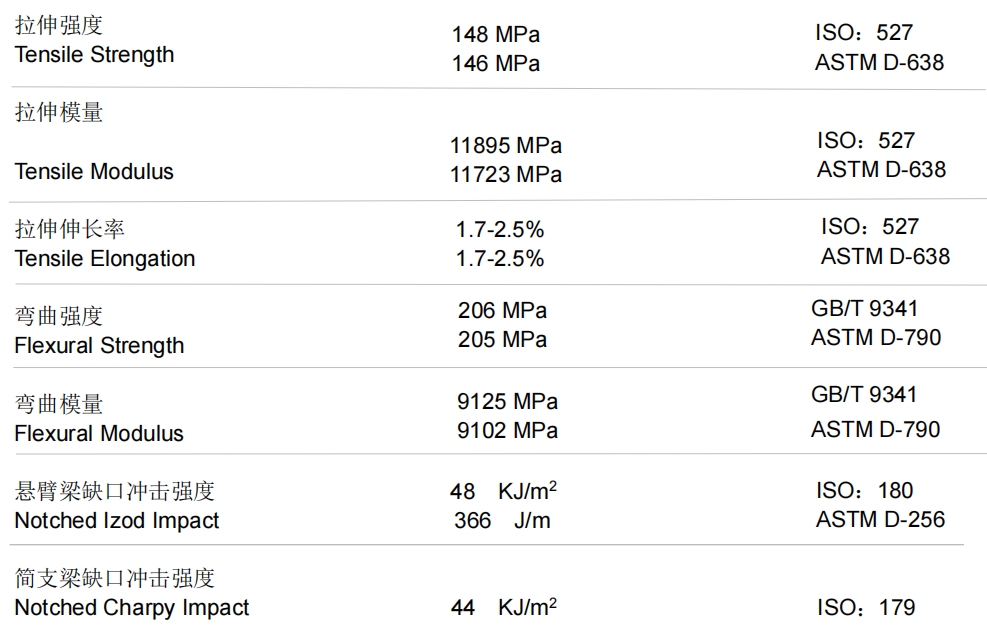

Self laboratory. Provide TDS and COA for every batch.

Fast shipping. Fast shipping to all capital cities or ports.

Favorable price. Free to get price.

Experienced team. With over 20 years experience expert team to provide assistance.

Full service. Through product discussion, performance analysis, composite selection, composite pellet production, after-sales tracking to injection molding techniques.

FAQ

Q. The product is easy to brittle, so changing to use long fiber reinforced thermoplastic materials can solve this problem?

A: The overall mechanical properties must be improved. The characteristics of long glass fiber and long carbon fiber are the advantages in mechanical properties. It has 1-3 times higher (toughness) than short fiber , and the tensile strength(strength and rigidity) is increased by 0.5-1 times.

Q. What are the differences and advantages of long fiber materials and short fibers?

A:Long-fiber reinforced composites show excellent mechanical properties compared to short fibers and are more suitable for applications requiring high strength. The impact performance of long fiber composites is 1-3 times higher than that of short fibers, tensile strength is more than 50% higher, and mechanical properties are 50-80% higher.

Q. How to choose the reinforcement method and length of the material when using long fiber reinforced thermoplastic material?

A: The selection of materials depend on the requirements of the products. It is necessary to assess how much the content is enhanced and how much length is more appropriate, which are depending on the performance requirements of the products.

Talk to an expert now

Email: sales02@lfrtplastic.com

WhatsApp: +86 139 5009 5727