-

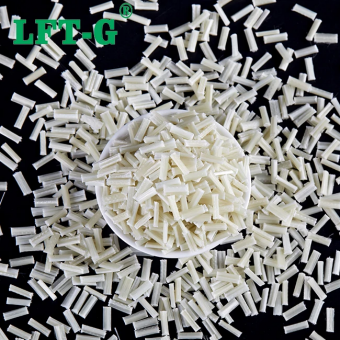

Xiamen LFT Polyamide 6,6 Long Glass Fiber Reinforced Thermoplastic Resin Nylon pelletsAbout Polyamide 66 Nylon 6,6 or PA 66 Is the most used polyamide High melting points, Abrasion resistance, Poor chemical resistance, and High water absorption What Are the Physical Properties of Polyamide? The most notable physical property of polyamide is its excellent wear resistance due to its low coefficient of friction created by its self-lubricating properties. Below is a list of other physical polyamide properties: Low density. Temperature resistance. Good impact resistance. High strength. Flexibility. What Are the Chemical Properties of Polyamide? The chemical property that makes polyamides stand out from other plastics is its excellent chemical resistance. Other chemical properties of polyamides are listed below: Very susceptible to osmosis. Nontoxic. Chemically stable. Nonflammable. About Long Glass Fiber LFT® is A LGF or LCF compound , through Centerfill manufacturing method which Offers exceptional Properties for weight and Cost reduction. With pellet length of 7-25mm and a range of 20%-70% of LGFor LCF content , LFT® Products family consist of Tailor made solutions to the Industry’s vast requirements , such as: LFT® - Fulfills heat stability requirements. LFT® - Offer Climate resistant Properties including UV resistance. LFT® - Ultra Performance & safety , with exceptional impact resistance Features, especially at low temperatures. LFT® - Cost Effective P.s. Centerfill manufacturing method:Centerfill uses our proprietary technology to introduce glass roving (GFR), which consists of several thousand filaments, into an impregnating device and melt the thermoplastic resin, uniformly impregnating between the filaments and then cutting them into pellets. Manufacture. What Are the Applications of Polyamide Long Fiber Reinforcement? 1. Engineering Plastics Engineering plastics are broadly defined as plastics that have better-performing properties than more widely used plastics. In the case of polyamides, these properties are good wear resistance, high strength, chemical resistance, and impact resistance. These better properties mean polyamides are used for helmets, bearings, supports, piping, and protective equipment. 2. Automotive Industry Polyamides are used in the automotive industry for their light weight, low cost, and good mechanical properties. Specific automotive applications include engine air intakes, car gate, engine covers, pulley tensioners, fuel lines, fuel pumps, lights, and vehicle trim. 3. Electrical and Electronics For a long time, polyamides have been the material of choice for electrical connectors. This is because electrical connectors, as well as other non-conductive electrical parts, require high heat resistance which polyamide can offer. Polyamide is also chosen due to its low cost, easy formability, high strength, and electrical insulation properties. They are frequently used to replace metal for applications in which light weighting, improved impact strength, elastic modulus, and material strength are required. Certifications & Lab Other Polyamide materials you may interested: PA12-LGF PPA-LGF About Xiamen LFT iamen LFT Composite Plastic Co.,LTD was established in 2009, is a brand-name global suppliers of long fiber reinforced thermoplastic materials integrating product research & developmen (R&D), production and sale marketing. Our LFT products have passed the ISO9001&16949 system certification and have obtained lots of national trademarks and patents, covering the fields of automotive, military parts and firearms, aerospace, new energy, medical equipment, power wind energy, sports...

- Polyamide 66 PA66 glass fiber reinforcement

- lft gf30 instead metal and steel lightweight

- easy to process good price

- high flexibility and durability composites plastic

- car frame injection molding

- hot sell compounds

Tags :

-

Xiamen LFT Polyamide 6,6 Long Glass Fiber Reinforced Thermoplastic Resin Nylon pelletsHigh melting points, Abrasion resistance, Poor chemical resistance, and High water absorptionview more

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文