Categories

new blog

What is thermoplastic composite?

In recent years, the fiber reinforced thermoplastic composites based on thermoplastic resin have developed rapidly, and the research and development of this kind of high-performance composite materials is setting off a high tide in the world. Thermoplastic composite material refers to thermoplastic polymer (such as polyether (PE), polyamide (PA), polyphenylene sulfide (PPS), polyether imide (PEI), polyether ketone ketone (PEKK) and polyether ether ketone (PEEK) as the matrix, Composite materials made of various continuous/discontinuous fibers (such as carbon fiber, glass fiber, aramidon fiber, etc.) as reinforcement materials.

Thermoplastic lipid-based composites mainly include long fiber reinforced granules (LFT) continuous fiber reinforced prepreg strip MT and glass fiber reinforced thermoplastic composites (CMT). According to the different requirements of use, the resin matrix includes PP/PAPRT/PELPCPES/PEEKPI/PA and other thermoplastic engineering plastics, and the dimension types include all possible fiber varieties such as glass dry vitriol and borodimension. With the development of thermoplastic resin matrix composite technology and the development of recyclable materials, the rapid development of the variety of recycled materials in developed countries in Europe and the United States has accounted for more than 30% of the total amount of tree matrix composite materials.

Thermoplastic matrix

Thermoplastic matrix is a thermoplastic material that has good mechanical properties and heat resistance and can be used to manufacture various industrial supplies. The thermoplastic matrix is characterized by high strength, high heat resistance and good corrosion resistance.

At present, the thermoplastic resins applied to the aviation field are mainly high-temperature resistant and high-performance resin substrates, including PEEK, PPS and PEI. Among them, amorphous PEI has more applications in aircraft structures than semi-crystalline PPS and high molding temperature PEEK because of its lower processing temperature and processing cost.

Thermoplastic resin has better mechanical properties and chemical corrosion resistance, higher service temperature, high specific strength and hardness, excellent fracture toughness and damage tolerance, excellent fatigue resistance, can mold complex geometric shapes and structures, adjustable thermal conductivity, recyclability, good stability in harsh environments, repeatable molding, welding and repair characteristics.

The composite material composed of thermoplastic resin and reinforcement material has durability, high toughness, high impact resistance and damage tolerance. Fiber prepreg no longer need to be stored at low temperature, unlimited prepreg storage period; Short molding cycle, weldable, high production efficiency, easy repair; Waste can be recycled; The product design freedom is large, can be made into complex shapes, forming adaptability and many other advantages.

Reinforcing material

The properties of thermoplastic composites not only depend on the properties of resins and reinforced fibers, but also closely related to the fiber reinforcement methods, which have three basic forms: short fiber reinforcement, long fiber reinforcement and continuous fiber reinforcement.

In general, the length of staple fiber reinforcement is 0.2 to 0.6mm, and since most fibers are less than 70μm in diameter, the staple fiber looks more like a powder. Short fiber reinforced thermoplastics are generally manufactured by mixing fibers into a molten thermoplastic. The fiber length and random orientation in the matrix make it relatively easy to achieve good wetting, and short fiber composites are the easiest to manufacture with minimal improvement in mechanical properties compared to long fiber and continuous fiber reinforced materials. Short fiber composites tend to be molded or extruded to form final parts because short fibers have less impact on fluidity.

The fiber length of long fiber reinforced composite materials is generally about 20mm, which is usually prepared by continuous fiber wetting resin and cutting into a certain length. The process commonly used is pultrusion molding, which is produced by drawing continuous roving mixed with fiber and thermoplastic resin through a special molding die. At present, the structural properties of long fiber reinforced PEEK thermoplastic composite materials through FDM printing can reach more than 200MPa, the modulus can reach more than 20GPa, and the performance will be better through injection molding.

The fibers in continuous fiber reinforced composites are "continuous", ranging in length from a few meters to several thousand meters, and continuous fiber composites generally provide laminates, prepregs or braided fabrics, etc., by impregnating continuous fibers with the desired thermoplastic matrix.

(LFT-G® Long Fiber Reinforced Thermoplastic Compounds)

What are the characteristics of fiber-reinforced composites

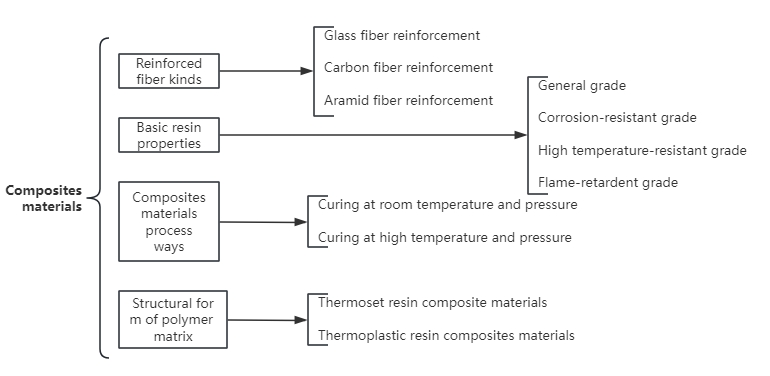

Fiber reinforced composites are composites formed by reinforced fiber materials, such as glass fiber, carbon fiber, aramid fiber, etc., and matrix materials through winding, molding or pultrusion molding process. According to the different reinforcement materials, common fiber reinforced composites are divided into glass fiber reinforced composite (GFRP), carbon fiber reinforced composite (CFRP) and aramid fiber reinforced composite (AFRP).

Because fiber reinforced composites have the following characteristics:

(1) The specific strength is high and the specific modulus is large

(2) Material properties are designable

(3) Good corrosion resistance and durability

(4) The coefficient of thermal expansion is similar to that of concrete

These characteristics make FRP materials to meet the needs of modern structures to large span, high-rise, heavy load, light, high strength and work in harsh conditions development, but also to meet the requirements of modern building construction industrialization development, so it is more and more widely used in a variety of civil buildings, Bridges, highways, oceans, hydraulic structures and underground structures and other fields.

Thermoplastic composites have great prospects for development

According to the report, the global thermoplastic composites market is expected to reach $66.2 billion by 2030, with a compound annual growth rate of 7.8% during the forecast period. This increase can be attributed to the growing product demand in the aerospace and automotive industries and the exponential growth in the construction industry. Thermoplastic composites are used in the construction of residential buildings, infrastructure and water supply facilities. Properties like excellent strength, toughness, and the ability to be recycled and reshaped make thermoplastic composites ideal for manufacturing in construction applications.

Thermoplastic composites will also be used in the production of storage tanks, lightweight structures, window frames, utility poles, railings, pipes, panels and doors. The automotive industry is one of the key application areas. Manufacturers are focusing on improving fuel efficiency, and to do so, they are replacing metal and steel with lightweight thermoplastic composites. Carbon fiber, for example, weighs one-fifth as much as steel, so it helps reduce the overall weight of the vehicle. According to the European Commission, the carbon emission cap target for cars will be raised from 130 grams per kilometer to 95 grams per kilometer by 2024, which is expected to increase the demand for thermoplastic composites in the automotive manufacturing industry.