Categories

new blog

Introduction

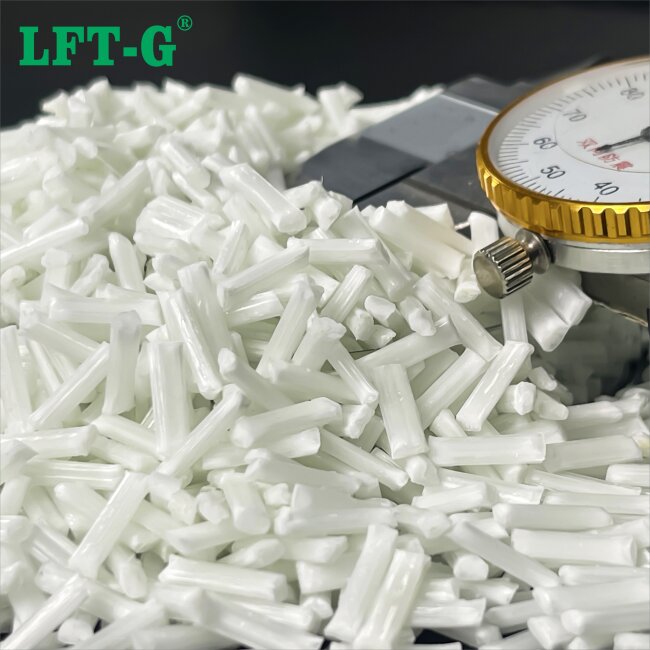

In the modern office furniture industry, material performance is critical to ensuring comfort, durability, and eco-friendliness. To address the shortcomings of traditional office chairs in strength, weight, customization, and environmental impact, we have developed a composite material based on plastic rice granules—PP filled with 40% long glass fiber. This innovative material not only breaks through physical performance limitations but also incorporates efficient manufacturing processes to achieve both environmental and economic benefits.

Material Introduction

1. Material Composition

PP + 40% long glass fiber is a high-performance composite material composed mainly of new polypropylene (PP) resin and 40% long glass fibers (LGF). Unlike traditional short glass fiber-reinforced PP, we use a Melt Impregnation Process, ensuring that the glass fibers are fully impregnated in the plastic matrix. This results in superior mechanical properties and durability.

2. Advantages of Long Glass Fiber Reinforcement

Enhanced Mechanical Properties: Compared to short glass fiber-reinforced PP, long glass fibers create an internal skeleton structure, improving tensile strength, flexural modulus, and impact toughness, making it ideal for high-strength applications.

Superior Dimensional Stability: Long glass fiber reinforcement reduces thermal expansion and shrinkage, improving stability under different environmental conditions and minimizing deformation risks.

Higher Fatigue Resistance: The uniform distribution of long glass fibers allows the material to withstand prolonged load-bearing applications, making it suitable for durable industrial products such as office chair seat shells and backrests.

Lightweight Design: While maintaining high strength, the material has a low density, effectively reducing product weight and meeting modern office furniture demands for both lightweight and high strength.

Production Process & Technical Advantages

1. Raw Material Preparation and Blending Process

Production of New Plastic Granules: We use newly produced plastic rice granules processed through high-precision crushing and extrusion to ensure uniform shape and consistent quality, serving as premium raw material for our composite.

Precise Addition of Long Glass Fiber: During blending, we maintain a strict 40% long glass fiber ratio to ensure that each batch meets the targeted reinforcement and high-performance standards.

Uniform Dispersion Technology: Advanced mixing equipment is employed to achieve thorough and even dispersion of the new plastic rice granules and long glass fibers, guaranteeing stable overall performance of the composite material.

Customized Color Masterbatch Addition: To meet customers’ color customization requirements, we can add color masterbatch into the granules during production for internal color customization. Additionally, clients may opt for further surface treatments such as painting or matte finishing to achieve the desired appearance.

2. Material Supply & Technical Support

Focus on Material Supply: We concentrate on supplying high-performance composite materials. Clients can use our materials for their own molding and processing, confident in the consistent quality of our raw materials.

Technical Support: While we do not handle the molding or injection molding process, we offer comprehensive technical documentation and process parameters to assist our clients in achieving optimal results during their manufacturing processes. We also support clients in meeting their color customization and surface treatment requirements.

Real-World Application in Office Chairs

1. Case Background & Customer Requirements

A renowned office furniture brand sought to address several key issues with conventional office chairs:

Structural deformation due to material fatigue over prolonged use;

Heavier products that are cumbersome to move and assemble frequently;

Growing market demand for customizable colors and personalized designs;

Environmental concerns in traditional material production.

2. Application Benefits and Improvement Outcomes

After integrating the PP with 40% long glass fiber and plastic rice granules, the office chairs experienced significant improvements in several areas:

Enhanced Structure: Long glass fibers effectively distribute external forces, enhancing fatigue resistance and preventing breakage.

Lightweight Design: Optimized formulations using plastic rice granules reduce the overall weight significantly, facilitating easier handling and assembly.

Customized Aesthetics: Surfaces can be treated with various customization techniques such as spraying, printing, or electroplating to match corporate culture and brand identity.

Eco-Friendly and Sustainable: The entire production process is optimized for energy efficiency and reduced emissions, and the material’s recyclability aligns with modern green manufacturing concepts.

3. Customer Project Photos & Customization Showcase

Eco-Friendly Practices & Future Outlook

Using newly produced plastic rice granules to create PP with 40% long glass fiber not only achieves comprehensive performance improvements but also offers significant environmental benefits:

Use of New Materials: We are committed to using only new raw materials—no recycled content—ensuring that the material quality and product performance meet the highest standards.

Recyclability: Although the raw materials are new, the composite is designed in accordance with modern recycling standards. At the end of its lifecycle, the product can be effectively recovered and reused.

Energy-Efficient Production: Continuous optimization of the manufacturing process results in low energy consumption and minimal emissions, aligning with green manufacturing principles.

Green Certifications: The product has received several international environmental certifications, underscoring our commitment to environmental protection and sustainability.

Looking ahead, we will continue to invest in material research and process innovation, aiming to deliver office furniture solutions that are not only high-performance but also eco-friendly, while driving the industry toward a low-carbon, green future.