Categories

new blog

At present, new energy technology, lightweight technology and intelligent network technology are the three major directions leading the development and technological innovation of the automotive industry, and carbon fiber composite materials have become the leader in the field of automotive lightweight technology with their light weight and high strength performance. Due to the particularity and complexity of carbon fiber composite materials, this paper explores the research and development technology of carbon fiber composite doors from the aspects of material selection, structural design and optimization, layup design and optimization, assembly connection design, simulation analysis, process molding, etc., in order to realize the lightweight, integrated and modular structure of the door.

Quotation

As one of the core technologies of new energy vehicles, lightweight technology is the only way to achieve energy saving and emission reduction, green development, and promote the win-win situation of the automotive industry, and has become the trend and trend of the development of the world's automobiles. The most direct and effective way to achieve automotive lightweight is to use lightweight materials. Carbon fiber reinforced plastic(CFRP) has the characteristics of high strength, high stiffness, high fracture toughness, corrosion resistance, high damping, etc., can greatly reduce the weight of the vehicle, the weight reduction ratio of 50%-60%, while greatly improving the service life of the vehicle, fuel efficiency and safety and comfort, has been recognized as the most ideal lightweight material in the automotive industry.

Material selection and testing

According to the performance of the parts, safety and durability and load conditions and other factors need to choose the appropriate material to form the manufacturing of automotive composite products. For the performance requirements of carbon fiber in the automotive industry, T300 and T700 are commonly used according to the strength level of carbon fiber; According to the form of intermediate material, there are prepreg, fabric, unidirectional belt, multi-axial braided cloth, etc. According to the size of the tow, 3K, 6K, 12K, 18k, 24K, 48K, etc. According to the typical resin types are epoxy resin, polyurethane, double horse resin, phenolic resin, polyimide resin, etc. The selection of the above material composition and material form requires comprehensive consideration of appearance, use environment, performance, cost, process and many other factors.

The door studied in this blog selected T300 grade, 3K tow of biaxial carbon fiber fabric reinforced epoxy resin based prepreg.

Structural design and optimization

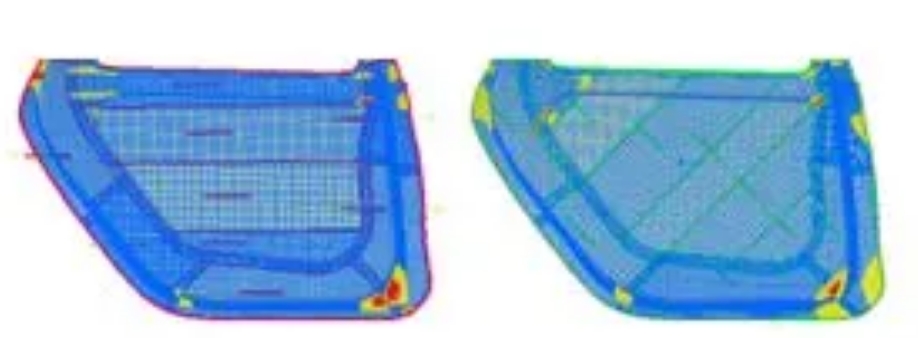

Model reduction design

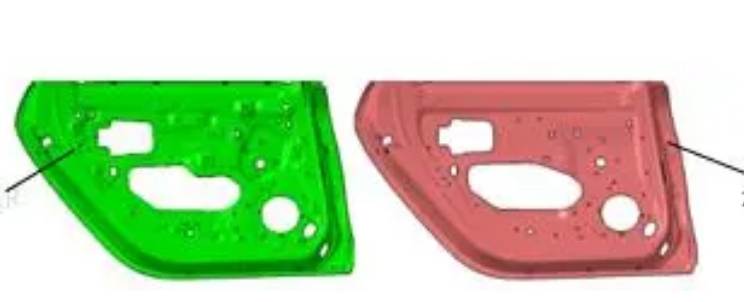

Since the forming of the composite material is made of multi-layer prepreg laying and superimposed pressure curing, the technicality of the fiber laying must be taken into account in the design of the composite material structure, that is, the Angle transition should be smooth as much as possible, and the characteristics of reinforcing bars and reinforcing grooving should be reduced. Therefore, after obtaining the door metal data model and design hard point information, it is necessary to simplify the model first, remove or reduce the reinforcement groove and reinforcement used to increase the stiffness, and deal with the transition at the turning area and rounded corners.

The structure of the metal model of the door inner plate and the composite model after simplified treatment are shown in the figure.

(The green part is the metal model, and the red part is the composite model)

The fillet radius of the laminated structure is related to the flexibility of the selected material, the mold and the thickness of the laminated part. The minimum radius of rounded corners needs to be determined with the manufacturing department. If the radius of rounded corners is too small, manufacturing defects such as fiber breaking, bridging and resin accumulation will occur in the corner area. Therefore, when designing the lamination structure of composite materials, a larger radius should be given at the corner as far as possible to avoid forming sharp corners.

The metal model at the corner of the door inner plate and the composite model after treatment are shown in the figure.

(The green part is the metal model, and the red part is the composite model)

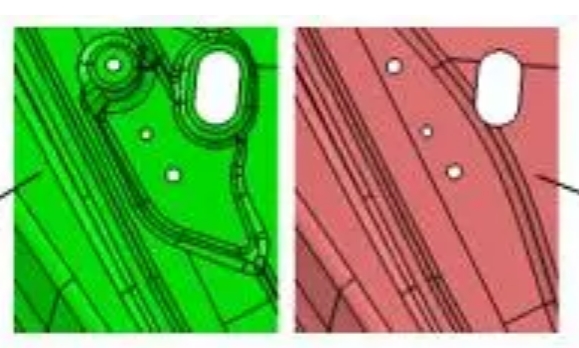

Integrated design

The traditional metal door structure generally includes outer plate, inner plate, window frame reinforcement plate, upper and lower hinge reinforcement plate, lock reinforcement plate, limiter reinforcement plate, waist line reinforcement plate and anti-collision beam and other structural components. The general steel metal door model explosion diagram is shown in the figure.

The advantage of composite materials is that several parts can be combined into an overall molding, in order to greatly reduce the number of parts and fasteners, simplify the connection and assembly, reduce the manufacturing cost of composite materials, and achieve the integration of materials, functions and structures.

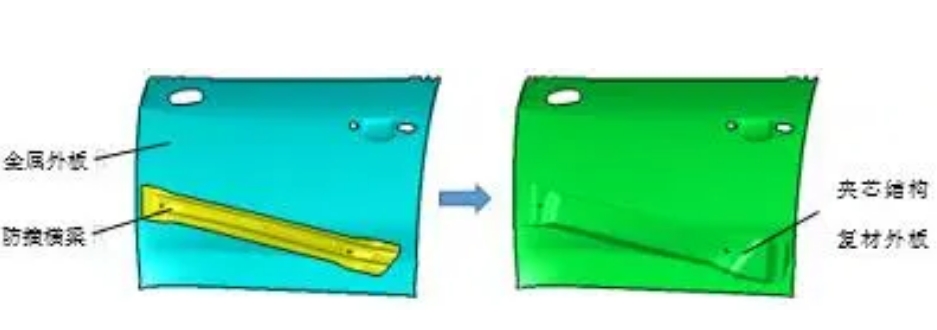

The integrated design of composite materials can integrate the door stopper stiffener plate, lock stiffener plate and hinge stiffener plate into the inner plate, solve the installation problem of the stopper and motion check under the premise of ensuring various regulatory requirements and performance indicators, and locally thicken the installation area of the stopper and hinge to improve local strength and stiffness; The anti-collision beam can also be integrated into the car door plate, and the design method of sandwich structure not only improves the overall stiffness of the outer plate, but also reduces the number of parts and assembly costs.

The carbon fiber composite foam sandwich structure with the anti-collision beam integrated into the outer plate is shown in the figure.

(On the left is the metal outer plate and anti-collision beam, and on the right is the composite outer plate)

Paving design and optimization

Layering design is the key to the design of composite structure. The core technology of layering design is how to transfer the excellent performance of single-layer structure to the composite structure components, so that the layering structure plays a role of connecting the previous and the next. Therefore, the design of composite layering should not only take into account the load condition and force transfer path of composite components, but also pay attention to the difficulty of the composite molding process. The basic principles of the structural design of carbon fiber composite materials are:

a) Principle of principal stress: the orientation of the fiber should be as consistent as possible with the direction of the principal stress of the component to give full play to the bearing performance of the fiber.

b) Principle of symmetrical balance: symmetrical balance laminate can avoid warping deformation caused by various coupling effects after curing.

c) Paving orientation principle: Generally use 0°, 90° and ±45° and other paving directions, minimize the paving direction to simplify the design and construction amount, and the minimum proportion of any paving layer is ≥10%.

d) Laying sequence principle: the same layering corner of the layering as evenly distributed as possible, generally not more than 4 layers, to prevent delamination, cracking damage.

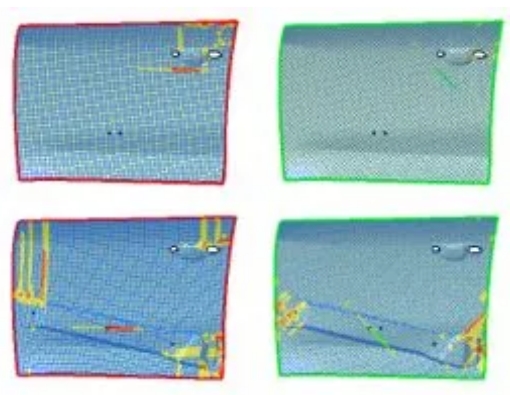

In the process of virtual process overlay, it is necessary to evaluate the overlay result. In the place with poor overlay, reasonable partitioning, changing the starting point of overlay, cutting edge, patch and other design methods should be adopted to optimize the partitioning or origin of overlay until the overlay analysis is completely passed.

In this blog, the carbon fiber composite outer plate is simple in structure, smooth in appearance, and directly covered with the selected prepreg material. The inner plate structure is more complex, in order to meet the technology of prepreg coating, it needs to be divided.

Based on Siemens Fibersim composite design software, the coverability of the outer and inner boards was analyzed and optimized. The coverability of the inner and outer boards was good and could meet the manufacturing needs.

The cladding effect of the door panel is shown in Figure, and the cladding effect of the door panel is shown in Figure.

(Exterior panel covering effect)

(Door interior panel overlay effect)

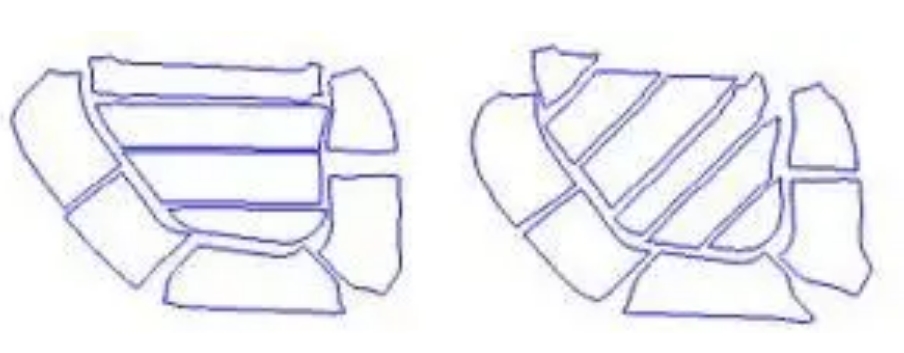

The spread diagram is used for the manufacture of composite doors, and the derived data can be directly used as the information identifiable by the automatic cloth cutting machine. The laying diagram of the inner panel of the carbon fiber composite door in the 0/90° direction is shown in the figure.

(Door interior panel layout development)

Connection design and assembly

In the composite connection design technology, it is generally necessary to consider the size of the transfer load of the structural part, the importance of the connection part, the material characteristics of the connected part, and other factors, in addition to environmental conditions, detectability, disassembly and repairability, as well as the process and manufacturing costs. Composite material connection is generally divided into mechanical connection, adhesive connection and hybrid connection.

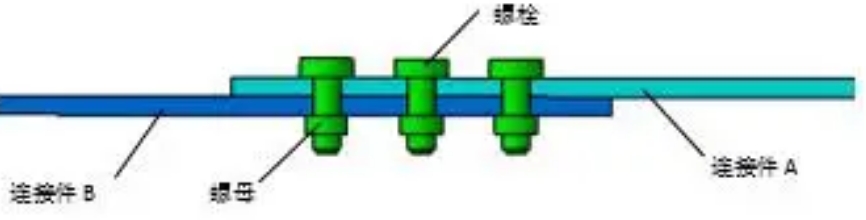

Mechanical connection

(From left to right: Connector B, nut, bolt, connector A)

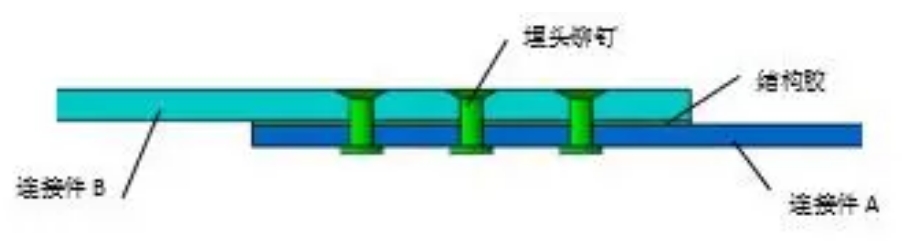

Gluing joint

The bonding of composite materials refers to the connection of parts into a non-removable whole with adhesive, which is a practical and effective connection technology, and is widely used in the connection of composite materials. The structural design of adhesive joint is also varied, according to the shape of the adhesive can be divided into plane lap, corner lap, T-shape bonding and tube, rod bonding and other forms; According to the bonding mode of the material, it can be divided into butt joint, lap joint, plug joint, step lap joint and so on.

The bonding connection diagram is shown in the figure.

(From left to right: Connector B, structural adhesive, connector A)

Hybrid connection

(From left to right: connector B, countersunk rivet, structural adhesive, connector A)

Process molding and processing

Process forming

The forming and manufacturing technology of advanced resin matrix composites can be basically divided into two categories, namely wet forming and dry forming.

Common wet forming methods include resin transfer molding (RTM), vacuum assisted molding (VARI) and so on.

The common forming methods of dry forming include autoclave forming, die forming and so on. For large size complex shape, high degree of integration of the parts, to use autoclave molding. For smaller high-precision parts, they are usually molded.

The selection of carbon fiber composite molding process is carried out at the same time as the selection of raw materials. In this paper, prepreg material is selected for both exterior and inner panels, and the forming method is determined to be dry molding. Considering its large size, high precision requirements for mounting surfaces and mounting holes, especially the surface quality of exterior panels should reach class A, and the structure of inner panels is complex and laminated with variable thickness, both inner panels and outer panels are molded by double-sided rigid prepreg molds.

processing

After curing and molding, the composite material also needs to be processed, which generally requires drilling, trimming, grinding, etc., especially for complex composite products similar to the door and the inner and outer plates, the number of holes is large, difficult, high precision, time-consuming processing and high cost.

The machining of carbon fiber composite material products is usually divided into traditional processing and advanced processing methods, the traditional machining method basically follows the metal processing technology and equipment, and the advanced composite material processing method greatly improves the processing quality and performance of the product. Traditional processing methods can not meet the processing quality requirements, but also may cause damage to the composite products, and even damage, advanced processing methods and equipment are expensive, and the processing cost is too high.

Advanced processing technology includes laser processing, high pressure water jet processing, ultrasonic processing and other technologies.

Concluding discussion

The above mentioned carbon fiber composite door structure design process and technology has been verified by a number of projects, but it is inevitable that there are shortcomings, such as economy, maintainability and manufacturing capacity and other factors have become obstacles for automotive companies to transfer to the carbon fiber market. With the continuous development of the carbon fiber industry and the increasing maturity of automotive lightweight technology, the application of carbon fiber composite materials in the automotive industry will be more extensive.