High-strength long glass fiber LGF modified nylon PA12 Long Glass fiber Reinforced Polyamide nylon PA12 has higher mechanical properties than ordinary modified PA12 nylon. Excellent long-term heat resistance, dimensional stability, can replace ordinary aluminum alloy materials, The cost is lower than that of metal materials.

-

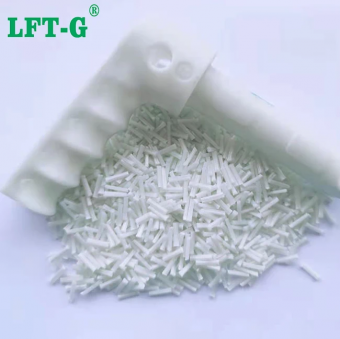

Xiamen LFT-G High strength Polyamide 12 composite lgf virgin white color for automotiveProduct number: PA12-NA-LGF Fiber specification: 20%-60% Product feature: High strength, High toughness and durability Product application: Suitable for automotive, sports parts, solar energy, photovoltaic industry and other industries.

- Nylon12 nylon high performance

- Durability pa

- Photovoltaic industry

- Injection grade pa12

- 24h service composite

- Supplier price

Tags :

-

Xiamen LFT-G Polyamide 12 filling long glass fiber compounds high rigidity and toughnessPA12 PA12 polyamide or nylon 12 Chemical and physical properties of PA12 PA12 is a linear, semi-crystalline - crystalline thermoplastic material from butadiene. Its properties are similar to PA11, but its crystal structure is different. PA12 is a good electrical insulator and will not be affected by moisture as other polyamides. PA12 has good impact resistance mechanical and chemical stability. There are many improved varieties of PA12 in terms of plasticizing and reinforcing properties. Compared with PA6 and PA66, these materials have lower melting point and density, and have very high moisture recovery. PA12 has no resistance to strong oxidizing acids. The viscosity of PA12 depends mainly on humidity, temperature and storage time. PA12 It's very liquid. The shrinkage rate of PA12 is between 0.5% and 2%, depending on the variety of PA12 material, wall thickness and other process conditions. PA12 compounds plastic Nylon glass fiber material is a kind of composite material, adding glass fiber on the basis of the original nylon material, so that the material has the following characteristics: High temperature resistance, good dimensional stability, good toughness, good insulation, corrosion resistance, high mechanical strength. LGF & SGF comparison Compared with the short fiber, it has more excellent performance in mechanical properties. It is more suitable for large products and structural parts. It has 1-3 times higher (toughness) than short fiber, and the tensile strength (strength and rigidity) is increased by 0.5-1 times. Datasheet for reference Application ■ Power tools: cutting machine, electric saw, electric drill, Angle grinder, polishing machine, electric hammer, electric pick, hot air gun and other models; ■ Automotive industry: cooling chamber, intake manifold, frame bracket, ventilation grille, door handle, throttle body and other models; ■ Machinery industry: water pump, water valve, bearing, shaft sleeve, gear, bracket and other models; ■ Sports equipment: ski equipment, baby carriage, fitness equipment parts and other models; ■ Office equipment: seat bracket, pulley, rotating shaft, shredder gear, printer parts and other models; Certification Factory Package Why choose us

- long glass fiber polyamide12

- long fibre reinforced thermoplastics resin

- long fiber compounds nylon12 best price

- lft-g PA12 manufacturer whole sell

- PA12 granules reinforced nylon material

- Polyamide12 nylon12 plastics automotive

Tags :

-

LFT Nylon 12 Polyamide plastic Long Glass Fiber Filled Composites pelletsPA 12 (also known as Nylon 12) is a good general-use plastic with broad additive applications and is known for its toughness, tensile strength, impact strength and ability to flex without fracture. PA 12 has long been used by injection molders due to these mechanical properties.

- High impact strength Injection molding

- modified thermoplastic resin LFRT

- structural parts car gears and bearings

- versatile engineering plastic

- polymers manufactuer of China factory price

- good price plastic resin PA 12

Tags :

-

Xiamen LFT Polyamide 12 Filled Long Glass Fiber Compounds China manufacturerProduct Name: Polyamide12 long glass fiber composite,Nylon 12 composite Certificated: SGS, 16949 system certificated,MSDS,and so on.

- LFT PA12 LGF long glass fiber virgin grade

- Nylon Fill Long Glass Fiber polyamide 12 high strength

- Nylon 12 Plastic Price high rigidity

- Nylon Composite thermoplastic resin

- Nylon 12 LGF20 instead metal and steel

- Polyamide12 with fiber glass low warpage

Tags :

-

Xiamen LFT Polyamide 12 filling long glass fiber compounds high rigidity and toughnessPA12 PA12 polyamide or nylon 12 Chemical and physical properties of PA12 PA12 is a linear, semi-crystalline - crystalline thermoplastic material from butadiene. Its properties are similar to PA11, but its crystal structure is different. PA12 is a good electrical insulator and will not be affected by moisture as other polyamides. PA12 has good impact resistance mechanical and chemical stability. There are many improved varieties of PA12 in terms of plasticizing and reinforcing properties. Compared with PA6 and PA66, these materials have lower melting point and density, and have very high moisture recovery. PA12 has no resistance to strong oxidizing acids. The viscosity of PA12 depends mainly on humidity, temperature and storage time. PA12 It's very liquid. The shrinkage rate of PA12 is between 0.5% and 2%, depending on the variety of PA12 material, wall thickness and other process conditions. PA12 compounds plastic Nylon glass fiber material is a kind of composite material, adding glass fiber on the basis of the original nylon material, so that the material has the following characteristics: High temperature resistance, good dimensional stability, good toughness, good insulation, corrosion resistance, high mechanical strength. LGF & SGF comparison Compared with the short fiber, it has more excellent performance in mechanical properties. It is more suitable for large products and structural parts. It has 1-3 times higher (toughness) than short fiber, and the tensile strength (strength and rigidity) is increased by 0.5-1 times. Datasheet for reference Application ■ Power tools: cutting machine, electric saw, electric drill, Angle grinder, polishing machine, electric hammer, electric pick, hot air gun and other models; ■ Automotive industry: cooling chamber, intake manifold, frame bracket, ventilation grille, door handle, throttle body and other models; ■ Machinery industry: water pump, water valve, bearing, shaft sleeve, gear, bracket and other models; ■ Sports equipment: ski equipment, baby carriage, fitness equipment parts and other models; ■ Office equipment: seat bracket, pulley, rotating shaft, shredder gear, printer parts and other models; Certification Factory Package Why choose usview more

-

Xiamen LFT Polyamide 12 filling long glass fiber compounds high rigidity and toughnessPA12 PA12 polyamide or nylon 12 Chemical and physical properties of PA12 PA12 is a linear, semi-crystalline - crystalline thermoplastic material from butadiene. Its properties are similar to PA11, but its crystal structure is different. PA12 is a good electrical insulator and will not be affected by moisture as other polyamides. PA12 has good impact resistance mechanical and chemical stability. There are many improved varieties of PA12 in terms of plasticizing and reinforcing properties. Compared with PA6 and PA66, these materials have lower melting point and density, and have very high moisture recovery. PA12 has no resistance to strong oxidizing acids. The viscosity of PA12 depends mainly on humidity, temperature and storage time. PA12 It's very liquid. The shrinkage rate of PA12 is between 0.5% and 2%, depending on the variety of PA12 material, wall thickness and other process conditions. PA12 compounds plastic Nylon glass fiber material is a kind of composite material, adding glass fiber on the basis of the original nylon material, so that the material has the following characteristics: High temperature resistance, good dimensional stability, good toughness, good insulation, corrosion resistance, high mechanical strength. LGF & SGF comparison Compared with the short fiber, it has more excellent performance in mechanical properties. It is more suitable for large products and structural parts. It has 1-3 times higher (toughness) than short fiber, and the tensile strength (strength and rigidity) is increased by 0.5-1 times. Datasheet for reference Application ■ Power tools: cutting machine, electric saw, electric drill, Angle grinder, polishing machine, electric hammer, electric pick, hot air gun and other models; ■ Automotive industry: cooling chamber, intake manifold, frame bracket, ventilation grille, door handle, throttle body and other models; ■ Machinery industry: water pump, water valve, bearing, shaft sleeve, gear, bracket and other models; ■ Sports equipment: ski equipment, baby carriage, fitness equipment parts and other models; ■ Office equipment: seat bracket, pulley, rotating shaft, shredder gear, printer parts and other models; Certification Factory Package Why choose usview more

-

Xiamen LFR reinforced Polyamide 12 nylon12 filling long glass fiber high tensile strength and toughnessWhat is PA12? The scientific name of PA12 is polydodecalactam, also known as nylon 12. The basic raw material for its polymerization is butadiene, which can depend on petrochemicals. It is a semi-crystalline - crystalline thermoplastic material. Its properties are similar to those of PA11, but the crystal structure is different; PA12 is an excellent electrical insulator and, like other polyamides, does not suffer from moisture-related insulating properties. PA12 has a number of improved plasticizing and reinforcing properties. What is PA12-LGF? PA12 filling long glass fiber material is a composite material, adding long glass fiber on the basis of the original nylon12 material, which makes the material have the following characteristics: High temperature resistance, good dimensional stability, good toughness, good insulation, good corrosion resistance, and high mechanical strength. Datasheet for reference Application Suitabel for automotive, sports parts, solar energy, photovoltaic industry and other industries. Details Number Color Length Sample MOQ Package Port of Loading Delivery time PA12-NA-LGF30 Natural color (or customzied) 12mm or so (or customized) Available 25KG 25KG/BAG Xiamen Port 7-15 days after shipment About us Xiamen LFT composite plastic Co., Ltd. is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) & Long Carbon Fiber Series (LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm length. The company's long-fiber continuous infiltration reinforced thermoplastics have passed ISO9001&16949 system certification, and the products have obtained lots of national trademarks and patents. Come to contact us for more technical support!

- LFT-G PA12 polyamide12

- thermoplastic pa12 lgf 30

- lft pa12 raw materials lgf white

- Injection mold plastic pa12 gfrp

- xiamen lft price good reinforced pa12

- sample available modified pa12 glass fiber

Tags :

-

Xiamen LFT Polyamide 12 Filled Long Glass Fiber Compounds China manufacturerProduct Name: Polyamide12 long glass fiber composite,Nylon 12 composite Certificated: SGS, 16949 system certificated,MSDS,and so on.view more

-

Xiamen LFT reinforced Polyamide 12 filling Long Glass Fiber for sports parts and solar energyWhat is Polyamide 12? Nylon 12 is the least dense of the nylon series at 1.02. Its characteristics include low water absorption, good dimensional stability, good low temperature resistance, up to -70℃; Low melting point, easy forming processing, forming temperature range is wide; Soft, chemical stability, oil resistance, wear resistance are good, and is a self-extinguishing material. The long-term use temperature is 80℃ (up to 90℃ after heat treatment), can work at 100℃ for a long time in oil, inert gas can work at 110℃ for a long time. What is Long Glass Fiber? Long fiber reinforced thermoplastics (fibrereinforced thermoplastics), referred to as LFT, refers to glass fiber reinforced composite materials (LFT) with a length of more than 5mm, has good molding processing properties, can be molded by injection, molding, extrusion and other processes, When forming, the plastic has good molding fluidity, and can be formed under low pressure. It can be formed into products with complex shapes, and the apparent mass of products is better than GMT. TDS of Polyamide 12 for reference only Application of Polyamide 12 filling long glass fiber compounds Packing Industry introduction LFT & LFRT, long fiber reinforced thermoplastic engineering plastics, compared to conventional short fiber reinforced thermoplastics, typically have a fiber length of less than 1 to 2 mm in conventional short fiber reinforced thermoplastics, while the LFT process the thermoplastic engineering plastics produced have been able to maintain fiber lengths above 5 to 25 mm. The long fiber is impregnated with a special resin system to obtain a long strip which is sufficiently wetted by the resin, and then cut into a desired length as required. The most used matrix resin is PP, by PA6, PA66, PPA, PA12, MXD6, PBT, PET, TPU, PPS, LCP, PEEK and the like. Conventional fibers include glass fiber and carbon fiber. Special fibers include basalt fiber and quartz fiber. The LFT of the long fiber material can achieve better mechanical properties. According to the final different applications, the finished product can be used for injection molding, extrusion and molding, Etc., directly used to replace steel and thermoset products.

- long glass fiber polyamide12 composites

- long fibre reinforced thermoplastics

- glass fiber reinforced plastics granules

- pa12 lgf30 thermoplastic resin polymers

- polyamide 12 lgf30 instead metal high rigidity

- lft pa6 modified nylon 12 injection molding

Tags :

-

Xiamen LFT-G Polyamide 12 filling long glass fiber compounds high rigidity and toughnessPA12 PA12 polyamide or nylon 12 Chemical and physical properties of PA12 PA12 is a linear, semi-crystalline - crystalline thermoplastic material from butadiene. Its properties are similar to PA11, but its crystal structure is different. PA12 is a good electrical insulator and will not be affected by moisture as other polyamides. PA12 has good impact resistance mechanical and chemical stability. There are many improved varieties of PA12 in terms of plasticizing and reinforcing properties. Compared with PA6 and PA66, these materials have lower melting point and density, and have very high moisture recovery. PA12 has no resistance to strong oxidizing acids. The viscosity of PA12 depends mainly on humidity, temperature and storage time. PA12 It's very liquid. The shrinkage rate of PA12 is between 0.5% and 2%, depending on the variety of PA12 material, wall thickness and other process conditions. PA12 compounds plastic Nylon glass fiber material is a kind of composite material, adding glass fiber on the basis of the original nylon material, so that the material has the following characteristics: High temperature resistance, good dimensional stability, good toughness, good insulation, corrosion resistance, high mechanical strength. LGF & SGF comparison Compared with the short fiber, it has more excellent performance in mechanical properties. It is more suitable for large products and structural parts. It has 1-3 times higher (toughness) than short fiber, and the tensile strength (strength and rigidity) is increased by 0.5-1 times. Datasheet for reference Application ■ Power tools: cutting machine, electric saw, electric drill, Angle grinder, polishing machine, electric hammer, electric pick, hot air gun and other models; ■ Automotive industry: cooling chamber, intake manifold, frame bracket, ventilation grille, door handle, throttle body and other models; ■ Machinery industry: water pump, water valve, bearing, shaft sleeve, gear, bracket and other models; ■ Sports equipment: ski equipment, baby carriage, fitness equipment parts and other models; ■ Office equipment: seat bracket, pulley, rotating shaft, shredder gear, printer parts and other models; Certification Factory Package Why choose usview more

-

Xiamen LFT-G High strength Polyamide 12 composite lgf virgin white color for automotiveProduct number: PA12-NA-LGF Fiber specification: 20%-60% Product feature: High strength, High toughness and durability Product application: Suitable for automotive, sports parts, solar energy, photovoltaic industry and other industries.view more

-

High strength PA12 nylon12 composite lgf virgin white color for automotiveProduct number: PA12-NA-LGF Fiber specification: 20%-60% Product feature: High strength, High toughness and durability Product application: Suitable for automotive, sports parts, solar energy, photovoltaic industry and other industries.

- Nylon12 filling long glass fiber reinforced plastic

- Durability high mechanical properties

- Photovoltaic industry compounds

- Injection grade thermoplastic resin

- 24h service customized plastic instead metal

- Supplier price good price pa6 composites

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文