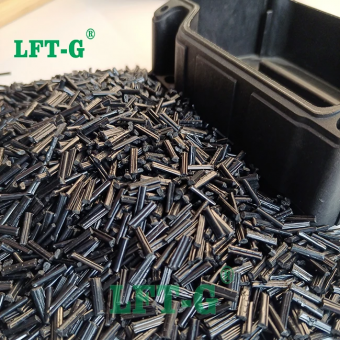

Long carbon fiber is a new material with high strength and high modulus and excellent mechanical properties. It is a microcrystalline graphite material obtained by carbonization and graphitization of organic fibers. Its specific gravity is less than 1/4 of steel, and its strength is higher than that of steel. Corrosion resistant, high modulus, no melting. And a variety of resin substrates after impregnation extrusion molding into pellets, long carbon fiber polymer. Can be used for direct molding products. In recent years, it has been widely used in aerospace, mechanical and electronic chemicals.

-

Xiamen LFT-G PLA Polylactic acid composite long carbon fiber thermoplastic resinWhat is long carbon fiber PLA? While biobased polylactic acid (PLA) thermoplastics are relatively eco-friendly and easy to recycle, composites such as carbon fibre are much stronger. Long carbon fiber reinforced PLA is an outstanding material that is strong, lightweight, has excellent layer bonding and low warpage. It has excellent layer adhesion and low warpage. Long carbon fiber PLA is stronger than other 3D-printed materials. Long carbon fiber filaments are not as strong as other 3D materials, but tougher. The increased rigidity of carbon fiber means increased structural support but reduced overall flexibility. It is slightly more brittle than regular PLA. When printed, the material is a dark glossy color that shimmers slightly under direct light. What is long carbon fiber? Long carbon fiber reinforced composites offer siginificant weight savings and provide optimum strength and stiffness properties in reinforced thermoplastics. The excellent mechanical properties of long carbon fiber reinforced composites make it an ideal replacement for metals. characteristic The fracture strain is moderate (8-10%), so the silk is not brittle, but strong toughness Very high melt strength and viscosity Good dimensional accuracy and stability Easy to handle on many platforms High attractive matte black surface Excellent impact resistance and lightness Application of long carbon fiber PLA materials Long carbon fiber PLA is an ideal material for frame, support, shell, propeller, chemical instrument and so on. Drone makers and RC enthusiasts especially like it, too. Ideal for applications requiring maximum stiffness and strength. Details Number PLA-NA-LCF30 Color Original black (can be customized) Length 12mm (can be customized) MOQ 20kg Package 20kg/bag Sample Available Delivery time 7-15 days after shipment Port of Loading Xiamen Port Exihibition We will offer you: 1. LFT & LFRT material technical parameters and leading edge design 2. Mold front design and recommendations 3. Provide technical support such as injection molding and extrusion molding

- PLA LCF original color resin made in China

- Polylactic acid filling long carbon fiber

- PLA resin lcf reinforced plastic pellets

- LFT cpmpounds pla manufacturer direct sell

- lcf reinforced material pla good price

- Thermoplastic pla lcf instead metal CF

Tags :

-

Xiamen LFT Polyamide12 filled Long Carbon Fiber composite lightweight sample availablePA12 information Long carbon chain nylon is a nylon with amide group in the main chain repeating unit of nylon molecule, and the length of methylene group between two amide groups is more than 10. We call it as long carbon chain nylon, including nylon 11, nylon 12, etc.. PA12 is nylon 12, also known as poly(dodecalactam) and poly(laurolactam), which is a kind of long carbon chain nylon. The basic raw material for polymerization is butadiene, a semi-crystalline - crystalline thermoplastic material. Nylon 12 is the most widely used long carbon chain nylon, it has most of the general properties of nylon, in addition to low water absorption, and has high dimensional stability, high temperature resistance, corrosion resistance, good toughness, easy processing and other advantages. Compared with PA11, another long carbon chain nylon material, PA12's raw material butadiene is only one-third the price of PA11's raw material castor oil, and can be used in most scenarios instead of PA11, and has wide applications in many fields such as automotive fuel hoses, air brake hoses, submarine cables, and 3D printing. Among long-chain nylon, PA12 has great advantages compared with other nylon materials, its advantages are the lowest water absorption, lowest density, low melting point, impact resistance, friction resistance, low temperature resistance, fuel resistance, good dimensional stability, good anti-noise effect, etc. PA12 has the properties of PA6, PA66 and polyolefin (PE, PP) at the same time, to achieve the combination of lightweight and physical and chemical properties, with performance It has the advantages of light weight and physical and chemical properties. PA12-LCF If the base material is compared to concrete, the fiber is like steel reinforcement, and mixing the two is like adding steel reinforcement to concrete. If there is only concrete, the castings will easily crack under external forces, but once the high-strength reinforcement is added to it and the concrete wraps it sufficiently, they will become a single unit. When the object is subjected to external forces, the rebar can withstand most of the external forces, making the structural strength of this whole very high. Carbon fiber has many excellent properties, high axial strength and modulus of carbon fiber, low density, high specific performance, no creep, resistance to ultra-high temperature in non-oxidizing environment, good fatigue resistance, specific heat and electrical conductivity between non-metal and metal, small coefficient of thermal expansion and anisotropy, good corrosion resistance, good X-ray transmittance. Good electrical and thermal conductivity, good electromagnetic shielding, etc. Compared with traditional glass fiber, carbon fiber has more than 3 times of Young's modulus; it is about 2 times of Young's modulus compared with Kevlar fiber, which is insoluble and swollen in organic solvents, acids and alkalis, and has outstanding corrosion resistance. Nylon itself is an engineering plastic with excellent performance, but moisture absorption, poor dimensional stability of products. Strength and hardness is also far from metal. In order to overcome these shortcomings, as early as before the 70s. People have used carbon fiber or other varieties of fibers for reinforcement to improve its performance. Carbon fiber reinforced nylon materials have developed rapidly in recent years, because nylon and carbon fiber are excellent performance in the field of engineering plastics materials, its compound material synthesis reflects the superiority of the two, such as strength and rigidity than unreinforced nylon is much higher, high temperature creep is small, thermal stability has improved significantly, good dimensional accuracy, wear resistance. Excellent damping, compared with glass fiber reinforced has better performance. Therefore, carbon fiber reinforced nylon (CF/PA) composites have developed rapidly in recent years. Datasheet for reference Nylon 12 has low water absorption, good low temperature resistance, good air tightness, excellent alkali and grease resistance, medium resistance to alcohols and inorganic dilute acids and aromatics, good mechanical and electrical properties, and is a self-extinguishing material. Application Suitable for the automotive, sports parts, solar energy, high-end toys and other industries. Other products you may wonder PP-LCF PA6-LCF PA66-LCF ...

- Nylon composite pellets Polymer granules

- Nylon polymer LCF manufacturer

- Modified materials Nylon PA12

- extrusion level Nylon modified

- pa lcf30 producer mess production good price

- carbone fiber reinforced pa12 pellets

Tags :

-

LFT Polyamide 6.6 Manufacturer Carbon Fiber filled Compounds green materialsPolyamide, which is also known by the trade name, Nylon, has excellent heat resistant properties, especially when combined with additives and filler materials.

- Nylon PA 66 thermoplastic resinforced material

- fiber filling polymer instead of metal steel

- Sample free natural plastic new CFRP

- engineering plastic structural parts

- modified resin good price low MOQ

- Car parts application good price

Tags :

-

LFT-G High Quality Nylon Polyamide 6 Long Carbon Fiber Reinforced PlasticsPolyamide 6 Profile PA66+LGF60 Polytron A60N01 is Natural, 60% Long Glass Fiber Reinforced, Heat Stabilized POLYAMIDE 66, The Glass Fibers are Chemically Coupled to the Polymer Matrix, The material is supplied in pellets that are typically 12mm in length. Fiber length is the length of the pellets. Typical applications include Injection Molding Applications. Production Process of LGF 1. Through the physical and chemical treatment of the original carbon fiber, it removes impurities, improves surface activity, and provides the mechanical properties and durability of pre-soaked materials. 2. Add resin, additives, etc., form a unique formula. Improve flowability, hardness, temperature stability. 3. The pre-treated carbon fiber is placed on the machine, and the resin is evenly covered on its surface. 4. Use the machine to solidify the material, and the fiber and resin are both sufficiently bonded. 5. According to the requirements of the product, cutting particles. What are the advantages and applications of Polyamide 6? Nylon 6 fibers are tough, possessing high tensile strength, elasticity, and luster. The fibers can absorb up to 2.4% of water, although this lowers tensile strength. The glass transition temperature of nylon 6 is 47 °C. Nylon 6 is generally white as a synthetic fiber but can be dyed in a solution bath before production for different color results. The tenacity of nylon 6 is 6–8.5 gf/D with a density of 1.14 g/cm3. Its melting point is 215 °C and can protect heat up to 150 °C on average. The applications of nylon 6 include construction material in many industries, including the automotive industry, electronic and electrotechnical industry, aircraft industry, clothing industry, and medicine. The advantages of nylon 6 are that its fibers are wrinkleproof and highly resistant to abrasion and chemicals such as acids and alkalis. Long fiber reinforced thermoplastics are an excellent option to consider for metal replacement at a fraction of the weight. About Xiamen LFT laboratory Warehouse Xiamen LFT has capabilities to provide assistance to you throughout an entire product launch - through product discussion, performance analysis, composite selection, composite pellet production, after-sales tracking. In addition, we provide guidance on injection molding techniques

- PA6 GFRP engineering plastic

- Manufacturer directly sell good price plastic

- Thermoplastic resin modified polymers

- customization service

- car parts lightweight instead metal

- composites made in China high toughness

Tags :

-

LFT Industrial Grade Polypropylene Long Carbon Fiber Reinforcement 20%-60%LFT Plastics are frequently used to replace metal for applications in which light weighting, improved impact strength, elastic modulus, and material strength are required.

- PP LCF CF compounds pellets granules

- Modified thermoplastic resin polymers

- easy to produce for car parts home appliance

- whole sell factory price 25kg/bag

- Low density and weight instead metal and steel

- can be customized plastic 10-12 mm length

Tags :

-

LFT Material Polypropylene Resin With Filler Carbon Fiber CompoundsThrough carbon fiber reinforcement, can improve the strength of polypropylene materials.

- High tensile strength stiffness plastic

- reinforcement nylon pp cf 30 cfrp

- carbon fiber filler composites

- Engineering use polymer good price

- Low MOQ 20kg/bag TDS properties

- customized sample free factory price

Tags :

-

Xiamen LFT Polypropylene PP Copolymer with Long Carbon Fiber Reinforcement PolymersLong fiber reinforced thermoplastics are an excellent option to consider for metal replacement at a fraction of the weight.

- Plastic increased mechanical properties

- Customization materials high quality ISO

- Injection molding plastic engineering factory

- LCF Carbon fiber filled thermoplastic resin

- long length pellets compounds manufacturer

- Continuous fibre long cut good performance

Tags :

-

Xiamen LFT Polyamide12 filled Long Carbon Fiber composite lightweight sample availablePA12 information Long carbon chain nylon is a nylon with amide group in the main chain repeating unit of nylon molecule, and the length of methylene group between two amide groups is more than 10. We call it as long carbon chain nylon, including nylon 11, nylon 12, etc.. PA12 is nylon 12, also known as poly(dodecalactam) and poly(laurolactam), which is a kind of long carbon chain nylon. The basic raw material for polymerization is butadiene, a semi-crystalline - crystalline thermoplastic material. Nylon 12 is the most widely used long carbon chain nylon, it has most of the general properties of nylon, in addition to low water absorption, and has high dimensional stability, high temperature resistance, corrosion resistance, good toughness, easy processing and other advantages. Compared with PA11, another long carbon chain nylon material, PA12's raw material butadiene is only one-third the price of PA11's raw material castor oil, and can be used in most scenarios instead of PA11, and has wide applications in many fields such as automotive fuel hoses, air brake hoses, submarine cables, and 3D printing. Among long-chain nylon, PA12 has great advantages compared with other nylon materials, its advantages are the lowest water absorption, lowest density, low melting point, impact resistance, friction resistance, low temperature resistance, fuel resistance, good dimensional stability, good anti-noise effect, etc. PA12 has the properties of PA6, PA66 and polyolefin (PE, PP) at the same time, to achieve the combination of lightweight and physical and chemical properties, with performance It has the advantages of light weight and physical and chemical properties. PA12-LCF If the base material is compared to concrete, the fiber is like steel reinforcement, and mixing the two is like adding steel reinforcement to concrete. If there is only concrete, the castings will easily crack under external forces, but once the high-strength reinforcement is added to it and the concrete wraps it sufficiently, they will become a single unit. When the object is subjected to external forces, the rebar can withstand most of the external forces, making the structural strength of this whole very high. Carbon fiber has many excellent properties, high axial strength and modulus of carbon fiber, low density, high specific performance, no creep, resistance to ultra-high temperature in non-oxidizing environment, good fatigue resistance, specific heat and electrical conductivity between non-metal and metal, small coefficient of thermal expansion and anisotropy, good corrosion resistance, good X-ray transmittance. Good electrical and thermal conductivity, good electromagnetic shielding, etc. Compared with traditional glass fiber, carbon fiber has more than 3 times of Young's modulus; it is about 2 times of Young's modulus compared with Kevlar fiber, which is insoluble and swollen in organic solvents, acids and alkalis, and has outstanding corrosion resistance. Nylon itself is an engineering plastic with excellent performance, but moisture absorption, poor dimensional stability of products. Strength and hardness is also far from metal. In order to overcome these shortcomings, as early as before the 70s. People have used carbon fiber or other varieties of fibers for reinforcement to improve its performance. Carbon fiber reinforced nylon materials have developed rapidly in recent years, because nylon and carbon fiber are excellent performance in the field of engineering plastics materials, its compound material synthesis reflects the superiority of the two, such as strength and rigidity than unreinforced nylon is much higher, high temperature creep is small, thermal stability has improved significantly, good dimensional accuracy, wear resistance. Excellent damping, compared with glass fiber reinforced has better performance. Therefore, carbon fiber reinforced nylon (CF/PA) composites have developed rapidly in recent years. Datasheet for reference Nylon 12 has low water absorption, good low temperature resistance, good air tightness, excellent alkali and grease resistance, medium resistance to alcohols and inorganic dilute acids and aromatics, good mechanical and electrical properties, and is a self-extinguishing material. Application Suitable for the automotive, sports parts, solar energy, high-end toys and other industries. Other products you may wonder PP-LCF PA6-LCF PA66-LCF ...view more

-

LFT Polyamide 66 high performance Long Carbon Fiber ReinforcementPA66 carbon fiber conductive plastic reinforced nylon plastic material, which combines the electrical conductivity of metal (a voltage applied to both ends of the material, through the material through the current) and the various properties of plastic (that is, material molecules are composed of many small, repeated structural units).Density (g/cm3) : 1.2 ~ 1.7, conductive anti-static plastic shielding efficiency (30MHz-10GHz) : 60-85dB;, mainly used in electronics, integrated circuit packaging, electromagnetic shielding and other fields.It is an important type of conductive polymer materials.Conductive anti-static material Semi-conductive shielding material used in medium and high voltage cables.Conductive plastic is a kind of functional polymer material which mixes resin and conductive material and is processed in the way of plastic.Conductive anti-static plastic product density is low, the weight is reduced by 50%;Bending modulus (MPa) : 2400 ~ 6000. With the increase of carbon fiber content, the tensile strength, flexural strength and flexural elastic modulus of the composites all increase.The impact strength of the cantilever beam increases first and then decreases, and the impact strength reaches its maximum value when the carbon fiber mass fraction is 30%, which is. The reason is that when the fiber content is relatively large, the fracture stress and its energy threshold increase, and the absorption methods such as elongation of fracture path caused by avoiding fiber, demonding of fiber-matrix interface and fiber pull-out are added, while the internal notching effect of fiber increases slowly, thus increasing the impact strength.When the mass fraction of carbon fiber is more than 30%, the internal notching effect of carbon fiber increases with the increase of carbon fiber content, and the impact strength decreases. For more technical questions, please contact us:+ 86 139 5009 5727 WEB:www.lft-g.com

- Long carbon fiber enhance pellets

- Roving carbon fiber PA66 instead metal and steel

- Nylon66 composite granules for injection

- High quality PA66 long fiber composite、

- Polyamide long fiber composite

- Virgin plastic PA6 LCF40 for car parts

Tags :

-

LFT High Quality Nylon Polyamide 6 Long Carbon Fiber Reinforced PlasticsPolyamide 6 Profile Production Process of LCF 1. Through the physical and chemical treatment of the original carbon fiber, it removes impurities, improves surface activity, and provides the mechanical properties and durability of pre-soaked materials. 2. Add resin, additives, etc., form a unique formula. Improve flowability, hardness, temperature stability. 3. The pre-treated carbon fiber is placed on the machine, and the resin is evenly covered on its surface. 4. Use the machine to solidify the material, and the fiber and resin are both sufficiently bonded. 5. According to the requirements of the product, cutting particles. What are the advantages and applications of Polyamide 6? Nylon 6 fibers are tough, possessing high tensile strength, elasticity, and luster. The fibers can absorb up to 2.4% of water, although this lowers tensile strength. The glass transition temperature of nylon 6 is 47 °C. Nylon 6 is generally white as a synthetic fiber but can be dyed in a solution bath before production for different color results. The tenacity of nylon 6 is 6–8.5 gf/D with a density of 1.14 g/cm3. Its melting point is 215 °C and can protect heat up to 150 °C on average. The applications of nylon 6 include construction material in many industries, including the automotive industry, electronic and electrotechnical industry, aircraft industry, clothing industry, and medicine. The advantages of nylon 6 are that its fibers are wrinkleproof and highly resistant to abrasion and chemicals such as acids and alkalis. Long fiber reinforced thermoplastics are an excellent option to consider for metal replacement at a fraction of the weight. About Xiamen LFT laboratory Warehouse Xiamen LFT has capabilities to provide assistance to you throughout an entire product launch - through product discussion, performance analysis, composite selection, composite pellet production, after-sales tracking. In addition, we provide guidance on injection molding techniquesview more

-

Xiamen LFT Polypropylene filled Long Carbon Fiber modified plastic high strength and rigidityCarbon Fiber Reinforced Plastic Carbon fiber reinforced plastic composite (CFRP) is a lightweight, strong material that can be used to make a wide range of products used in everyday life. It is a term used to describe fiber reinforced composites with carbon fiber as the main structural component. Note that the "P" in CFRP can also stand for "plastic" rather than "polymer." Typically, CFRP composites use thermosetting resins such as epoxy, polyester, or vinyl esters. Despite the use of thermoplastic resins in CFRP composites, "carbon fiber reinforced thermoplastic composites" often uses its own acronym, CFRTP composites. LFT-G focuses on LFT&LFRT. Long Glass Fiber Series (LGF) & Long Carbon Fiber Series. Compared with Short Carbon Fiber, Long Carbon Fiber has more excellent performance in mechanical properties. It is more suitable for large products and structural parts. It has 1-3 times higher (toughness) than Short Carbon Fiber, and the tensile strength(strength and rigidity) is increased by 0.5-1 times. Properties of PP CF Composites Composites reinforced with carbon fiber are different from other FRP composites that use traditional materials such as glass fiber or arylon fiber. Advantages of CFRP composites include: Light weight: Conventional fiberglass reinforced composites using continuous fiberglass and 70% fiberglass (glass weight/gross weight) typically have a density of 0.065 lb/cubic inch. A CFRP composite with the same 70% fiber weight might typically have a density of 0.055 lb/cubic inch. Increased strength: Carbon fiber composites not only weigh less, but CFRP composites are stronger and stiffer per unit weight. This is true when comparing carbon fiber composites to glass fibers, and even more so when comparing metals. For example, when comparing steel to CFRP composites, a good rule of thumb is that a carbon fiber structure of the same strength typically weighs 1/5 as steel. You can imagine why car companies are looking into using carbon fiber instead of steel. When comparing CFRP composites to aluminum (one of the lightest metals used), the standard assumption is that an aluminum structure of the same strength might weigh 1.5 times as much as a carbon fiber structure. Of course, there are many variables that can change this comparison. Grades and qualities of materials may vary, and for composites, the manufacturing process, fiber structure and quality need to be considered. Application of PP-LCF Long Carbon Fiber as the reinforcement material of CFRP, its proportion is only 1/4 of iron, specific strength is 10 times that of iron, elastic modulus is 7 times that of iron, carbon fiber excellent physical properties are played in various fields from sports goods to aircraft. Details of product Number Length Color Sample Package Delivery time Port of Loading Freight PP-NA-LCF30 5-25mm Original color (can be customized) Available 20kg a bag 7-15days after shipment Xiamen Port Depending on your destination Related products PA6-LCF PA66-LCF About Xiamen LFT Composite plastic Co., Ltd. A new material enterprise that develops and produces its own brand of LFT long glass fiber and long carbon fiber. It fills the blank of domestic high-end long carbon fiber LFT materials, and is more customized and shortened the production cycle compared with foreign companies. In addition, our company has sales and service offices in Istanbul, Zhejiang, Jiangsu, Guangzhou, etc. It can more easily to understand customer needs and has more convenient after sale.

- Long fiber reinforced thermoplastics

- Modified materials of long carbon fiber

- Polymer composites automotive parts

- The modified PP high performance

- Long carbon fiber filling plastic PP car part use

- LFT-G brand materials pp polymer chemical resistance

Tags :

-

Xiamen LFT Polyamide12 filled Long Carbon Fiber composite lightweight sample availablePA12 information Long carbon chain nylon is a nylon with amide group in the main chain repeating unit of nylon molecule, and the length of methylene group between two amide groups is more than 10. We call it as long carbon chain nylon, including nylon 11, nylon 12, etc.. PA12 is nylon 12, also known as poly(dodecalactam) and poly(laurolactam), which is a kind of long carbon chain nylon. The basic raw material for polymerization is butadiene, a semi-crystalline - crystalline thermoplastic material. Nylon 12 is the most widely used long carbon chain nylon, it has most of the general properties of nylon, in addition to low water absorption, and has high dimensional stability, high temperature resistance, corrosion resistance, good toughness, easy processing and other advantages. Compared with PA11, another long carbon chain nylon material, PA12's raw material butadiene is only one-third the price of PA11's raw material castor oil, and can be used in most scenarios instead of PA11, and has wide applications in many fields such as automotive fuel hoses, air brake hoses, submarine cables, and 3D printing. Among long-chain nylon, PA12 has great advantages compared with other nylon materials, its advantages are the lowest water absorption, lowest density, low melting point, impact resistance, friction resistance, low temperature resistance, fuel resistance, good dimensional stability, good anti-noise effect, etc. PA12 has the properties of PA6, PA66 and polyolefin (PE, PP) at the same time, to achieve the combination of lightweight and physical and chemical properties, with performance It has the advantages of light weight and physical and chemical properties. PA12-LCF If the base material is compared to concrete, the fiber is like steel reinforcement, and mixing the two is like adding steel reinforcement to concrete. If there is only concrete, the castings will easily crack under external forces, but once the high-strength reinforcement is added to it and the concrete wraps it sufficiently, they will become a single unit. When the object is subjected to external forces, the rebar can withstand most of the external forces, making the structural strength of this whole very high. Carbon fiber has many excellent properties, high axial strength and modulus of carbon fiber, low density, high specific performance, no creep, resistance to ultra-high temperature in non-oxidizing environment, good fatigue resistance, specific heat and electrical conductivity between non-metal and metal, small coefficient of thermal expansion and anisotropy, good corrosion resistance, good X-ray transmittance. Good electrical and thermal conductivity, good electromagnetic shielding, etc. Compared with traditional glass fiber, carbon fiber has more than 3 times of Young's modulus; it is about 2 times of Young's modulus compared with Kevlar fiber, which is insoluble and swollen in organic solvents, acids and alkalis, and has outstanding corrosion resistance. Nylon itself is an engineering plastic with excellent performance, but moisture absorption, poor dimensional stability of products. Strength and hardness is also far from metal. In order to overcome these shortcomings, as early as before the 70s. People have used carbon fiber or other varieties of fibers for reinforcement to improve its performance. Carbon fiber reinforced nylon materials have developed rapidly in recent years, because nylon and carbon fiber are excellent performance in the field of engineering plastics materials, its compound material synthesis reflects the superiority of the two, such as strength and rigidity than unreinforced nylon is much higher, high temperature creep is small, thermal stability has improved significantly, good dimensional accuracy, wear resistance. Excellent damping, compared with glass fiber reinforced has better performance. Therefore, carbon fiber reinforced nylon (CF/PA) composites have developed rapidly in recent years. Datasheet for reference Nylon 12 has low water absorption, good low temperature resistance, good air tightness, excellent alkali and grease resistance, medium resistance to alcohols and inorganic dilute acids and aromatics, good mechanical and electrical properties, and is a self-extinguishing material. Application Suitable for the automotive, sports parts, solar energy, high-end toys and other industries. Other products you may wonder PP-LCF PA6-LCF PA66-LCF ...view more

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文