-

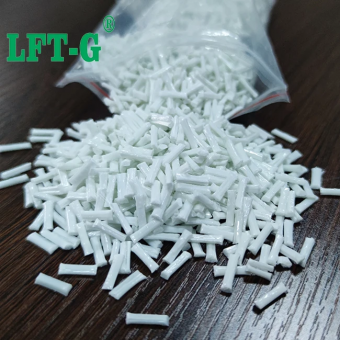

Xiamen LFT Polyamide 12 filling long glass fiber compounds high rigidity and toughnessPA12 PA12 polyamide or nylon 12 Chemical and physical properties of PA12 PA12 is a linear, semi-crystalline - crystalline thermoplastic material from butadiene. Its properties are similar to PA11, but its crystal structure is different. PA12 is a good electrical insulator and will not be affected by moisture as other polyamides. PA12 has good impact resistance mechanical and chemical stability. There are many improved varieties of PA12 in terms of plasticizing and reinforcing properties. Compared with PA6 and PA66, these materials have lower melting point and density, and have very high moisture recovery. PA12 has no resistance to strong oxidizing acids. The viscosity of PA12 depends mainly on humidity, temperature and storage time. PA12 It's very liquid. The shrinkage rate of PA12 is between 0.5% and 2%, depending on the variety of PA12 material, wall thickness and other process conditions. PA12 compounds plastic Nylon glass fiber material is a kind of composite material, adding glass fiber on the basis of the original nylon material, so that the material has the following characteristics: High temperature resistance, good dimensional stability, good toughness, good insulation, corrosion resistance, high mechanical strength. LGF & SGF comparison Compared with the short fiber, it has more excellent performance in mechanical properties. It is more suitable for large products and structural parts. It has 1-3 times higher (toughness) than short fiber, and the tensile strength (strength and rigidity) is increased by 0.5-1 times. Datasheet for reference Application ■ Power tools: cutting machine, electric saw, electric drill, Angle grinder, polishing machine, electric hammer, electric pick, hot air gun and other models; ■ Automotive industry: cooling chamber, intake manifold, frame bracket, ventilation grille, door handle, throttle body and other models; ■ Machinery industry: water pump, water valve, bearing, shaft sleeve, gear, bracket and other models; ■ Sports equipment: ski equipment, baby carriage, fitness equipment parts and other models; ■ Office equipment: seat bracket, pulley, rotating shaft, shredder gear, printer parts and other models; Certification Factory Package Why choose us

- long glass fiber polyamide12

- long fibre reinforced thermoplastics resin

- long fiber compounds nylon12 best price

- lft-g PA12 manufacturer whole sell

- granules reinforced nylon material

- Polyamide12 plastics automotive made in China

Tags :

-

Xiamen LFT-G Polyamide 6 filling Long Carbon Fiber reinforced thermoplastic materialPolyamide 6 Nylon 6 (PA6) as a general engineering plastics, with light weight, wear resistance, corrosion resistance, good toughness and other characteristics, and as a common thermoplastic resin, its heating can be softened, cooling can be hardened, and can be repeatedly heated softening, cooling hardening, repeated processing characteristics. Long carbon fiber With high strength, high modulus, large specific surface area and aspect ratio, and high electrical conductivity, carbon fiber fabrics have superior mechanical properties compared to glass fiber and can provide maximum strength in the fiber direction. Carbon fiber reinforced composites are stronger than polymer matrix materials, while maintaining the advantage of light weight, and are gradually replacing traditional metal materials in the fields of electronic products, electric vehicles, medical devices, industrial equipment and sports and leisure products. LCF VS SCF Advantage of Long Carbon Fiber filled (1) High strength and high toughness (2) Small coefficient of thermal expansion (3) Low hardness and light weight (4) Corrosion resistance and aging resistance (5) Temperature resistance TDS of PA6 for reference Application of PA6 Suitable for manufacturing helmets, car bumps and treadmills etc. Certifications Factory & Warehouse Teams & Customers About us Xiamen LFT composite plastic Co., Ltd is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) & Long Carbon Fiber Series (LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm in length. The company's continuous infiltration reinforced thermoplastics have passed ISO9001&16949 system certification, and the products have obtained lots of national trademarks and patents.

- long fibre reinforced thermoplastics

- carbon fiber reinforced plastics granules

- long carbon fiber reinforced pa6

- long fiber compounds pa6 nylon

- long fiber composite pa6 granules

- long carbon fiber polyamide6 higher peroformance

Tags :

-

Xiamen LFT Polyamide 12 filling long carbon fiber compounds high impact resistance for car partsLong carbon fiber Carbon fiber has many excellent properties, high axial strength and modulus, low density, high specific performance, no creep, super high temperature resistance in non-oxidizing environment, good fatigue resistance, specific heat and electrical conductivity between non-metal and metal, small coefficient of thermal expansion and anisotropy, good corrosion resistance, good X-ray transmission. Good electrical and thermal conductivity, good electromagnetic shielding, etc. Compared with traditional glass fiber, carbon fiber has more than 3 times of Young's modulus; it is about 2 times of Young's modulus compared with Kevlar fiber, which is insoluble and swollen in organic solvents, acids and alkalis, and has outstanding corrosion resistance. But is there a way to reduce the price of carbon fiber? That is to mix it with relatively cheap nylon material to form a composite material with good performance and meet the requirements. In that case, there is no doubt that carbon fiber nylon will definitely have a place in the composite material. Nylon itself is an engineering plastic with excellent performance, but moisture absorption, poor dimensional stability of products. Strength and hardness are also far from metal. In order to overcome these shortcomings, as early as before the 70s. People have used carbon fiber or other varieties of fibers for reinforcement to improve its performance. Carbon fiber reinforced nylon materials have developed rapidly in recent years, because nylon and carbon fiber are excellent performance in the field of engineering plastics materials, its compound material synthesis reflects the superiority of the two, such as strength and rigidity than unreinforced nylon is much higher, high temperature creep is small, thermal stability has improved significantly, good dimensional accuracy, wear resistance. Excellent damping, compared with glass fiber reinforced has better performance. Therefore, carbon fiber reinforced nylon (CF / PA) composites have developed rapidly in recent years. And for 3D printing using SLS technology is the most suitable technical means to achieve carbon fiber reinforced nylon. TDS for reference Application production process Company profile Xiamen LFT composite plastic Co., Ltd is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) & Long Carbon Fiber Series (LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm in length. The company's continuous infiltration reinforced thermoplastics have passed ISO9001&16949 system certification, and the products have obtained lots of national trademarks and patents.

- long carbon fiber reinforced pa12

- pure PA 12 manufacturers supplier factory CFRP

- pa6 lcf CF 30 car frame

Tags :

-

Xiamen LFT-G Polyamide 12 filling long glass fiber compounds high rigidity and toughnessPA12 PA12 polyamide or nylon 12 Chemical and physical properties of PA12 PA12 is a linear, semi-crystalline - crystalline thermoplastic material from butadiene. Its properties are similar to PA11, but its crystal structure is different. PA12 is a good electrical insulator and will not be affected by moisture as other polyamides. PA12 has good impact resistance mechanical and chemical stability. There are many improved varieties of PA12 in terms of plasticizing and reinforcing properties. Compared with PA6 and PA66, these materials have lower melting point and density, and have very high moisture recovery. PA12 has no resistance to strong oxidizing acids. The viscosity of PA12 depends mainly on humidity, temperature and storage time. PA12 It's very liquid. The shrinkage rate of PA12 is between 0.5% and 2%, depending on the variety of PA12 material, wall thickness and other process conditions. PA12 compounds plastic Nylon glass fiber material is a kind of composite material, adding glass fiber on the basis of the original nylon material, so that the material has the following characteristics: High temperature resistance, good dimensional stability, good toughness, good insulation, corrosion resistance, high mechanical strength. LGF & SGF comparison Compared with the short fiber, it has more excellent performance in mechanical properties. It is more suitable for large products and structural parts. It has 1-3 times higher (toughness) than short fiber, and the tensile strength (strength and rigidity) is increased by 0.5-1 times. Datasheet for reference Application ■ Power tools: cutting machine, electric saw, electric drill, Angle grinder, polishing machine, electric hammer, electric pick, hot air gun and other models; ■ Automotive industry: cooling chamber, intake manifold, frame bracket, ventilation grille, door handle, throttle body and other models; ■ Machinery industry: water pump, water valve, bearing, shaft sleeve, gear, bracket and other models; ■ Sports equipment: ski equipment, baby carriage, fitness equipment parts and other models; ■ Office equipment: seat bracket, pulley, rotating shaft, shredder gear, printer parts and other models; Certification Factory Package Why choose usview more

-

LFT-G TPU Thermoplastic Urethane filled long glass fiber compoundsWhat is TPU? TPU(Thermoplastic polyurethanes) name is elastomer rubber. It is mainly divided into polyester type and polyether type, its hardness range is wide (60HA-85HD), wear resistance, oil resistance, transparent, good elasticity, in daily necessities, sports goods, toys, decorative materials and other fields are widely used, halogen-free flame retardant TPU can also replace soft PVC to meet more and more fields of environmental protection requirements. The so-called elastic body refers to the glass transition temperature is lower than the room temperature, elongation at break >50%, the external force removed after the good recovery polymer material. Polyurethane elastomer is a special category of elastomer, polyurethane elastomer hardness range is very wide, performance range is very wide, so polyurethane elastomer is a kind of polymer material between rubber and plastic. It can be heated plasticized and has little or no crosslinking in chemical structure. Its molecules are basically linear, but there is some physical crosslinking. This type of polyurethane is called a TPU. Why filling long glass fiber? Long glass fiber reinforced composites can solve your problems when other methods of reinforced plastics do not provide the performance you need or if you want to replace metal with plastic. Long glass fiber reinforced composites can cost-effectively reduce the cost of goods and effectively improve the mechanical properties of engineering polymers, and increase the durability by forming long fibers to form a long-fiber-reinforced internal skeleton network. Performance is preserved in a wide range of environments. Compared with Short glass fiber Application Car doors and windows, Safty toe, Mechanical parts, Pneumatic nail gun boxes, Professional power tools, Nut and bolts, Etc. About us Xiamen LFT composite plastic Co., Ltd. is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) and Long Carbon Fiber Series (LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm in legnth. The company's long-fiber continuous infiltration reinofrced thermoplastics have passed ISO9001&16949 system certification, and the products have obtained lots of national trademarks and patents. Quality Management System ISO9001&16949 Certification National Laboratory Accreditation Certificate Modified Plastics Innovation Enterprise Honorary Certificate Heavy metal REACH & ROHS testing

- tpu lft polymers manufacturers

- glass fiber reinforced plastics granules

- long glass fiber TPU GFRP

- long fiber composite TPU granules

- long glass fiber reinforced TPU lft

Tags :

-

Xiamen LFT Polyamide 66 Reinforced resin Long Glass fiberReinforced Polyamide (nylon) resin PA66 Long Glass fiber is a mechanical component shield for high rigidity and dimensional stability, and is widely used in mechanical and electrical parts used in the electrical and electronic industry.

- Glass fibre reinforced polyamide thermoplastic resin

- Long Fiber reinforced Thermoplastics

- Thermoplastic Polymer low warpage

- Nylon Long glass fiber high quality made in China

- Application electrical parts PA66 Polyamide

Tags :

-

LFT-G Polyamide 12 long carbon fiber reinforced compounds nylon for car partsLong carbon fiber Carbon fiber has many excellent properties, high axial strength and modulus, low density, high specific performance, no creep, super high temperature resistance in non-oxidizing environment, good fatigue resistance, specific heat and electrical conductivity between non-metal and metal, small coefficient of thermal expansion and anisotropy, good corrosion resistance, good X-ray transmission. Good electrical and thermal conductivity, good electromagnetic shielding, etc. Compared with traditional glass fiber, carbon fiber has more than 3 times of Young's modulus; it is about 2 times of Young's modulus compared with Kevlar fiber, which is insoluble and swollen in organic solvents, acids and alkalis, and has outstanding corrosion resistance. But is there a way to reduce the price of carbon fiber? That is to mix it with relatively cheap nylon material to form a composite material with good performance and meet the requirements. In that case, there is no doubt that carbon fiber nylon will definitely have a place in the composite material. Nylon itself is an engineering plastic with excellent performance, but moisture absorption, poor dimensional stability of products. Strength and hardness are also far from metal. In order to overcome these shortcomings, as early as before the 70s. People have used carbon fiber or other varieties of fibers for reinforcement to improve its performance. Carbon fiber reinforced nylon materials have developed rapidly in recent years, because nylon and carbon fiber are excellent performance in the field of engineering plastics materials, its compound material synthesis reflects the superiority of the two, such as strength and rigidity than unreinforced nylon is much higher, high temperature creep is small, thermal stability has improved significantly, good dimensional accuracy, wear resistance. Excellent damping, compared with glass fiber reinforced has better performance. Therefore, carbon fiber reinforced nylon (CF / PA) composites have developed rapidly in recent years. And for 3D printing using SLS technology is the most suitable technical means to achieve carbon fiber reinforced nylon. TDS for reference Application Our company Xiamen LFT composite plastic Co., Ltd is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) & Long Carbon Fiber Series (LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm in length. The company's continuous infiltration reinforced thermoplastics have passed ISO9001&16949 system certification, and the products have obtained lots of national trademarks and patents.view more

-

LFT-G Polyamide 12 long carbon fiber reinforced compounds nylon for car partsLong carbon fiber Carbon fiber has many excellent properties, high axial strength and modulus, low density, high specific performance, no creep, super high temperature resistance in non-oxidizing environment, good fatigue resistance, specific heat and electrical conductivity between non-metal and metal, small coefficient of thermal expansion and anisotropy, good corrosion resistance, good X-ray transmission. Good electrical and thermal conductivity, good electromagnetic shielding, etc. Compared with traditional glass fiber, carbon fiber has more than 3 times of Young's modulus; it is about 2 times of Young's modulus compared with Kevlar fiber, which is insoluble and swollen in organic solvents, acids and alkalis, and has outstanding corrosion resistance. But is there a way to reduce the price of carbon fiber? That is to mix it with relatively cheap nylon material to form a composite material with good performance and meet the requirements. In that case, there is no doubt that carbon fiber nylon will definitely have a place in the composite material. Nylon itself is an engineering plastic with excellent performance, but moisture absorption, poor dimensional stability of products. Strength and hardness are also far from metal. In order to overcome these shortcomings, as early as before the 70s. People have used carbon fiber or other varieties of fibers for reinforcement to improve its performance. Carbon fiber reinforced nylon materials have developed rapidly in recent years, because nylon and carbon fiber are excellent performance in the field of engineering plastics materials, its compound material synthesis reflects the superiority of the two, such as strength and rigidity than unreinforced nylon is much higher, high temperature creep is small, thermal stability has improved significantly, good dimensional accuracy, wear resistance. Excellent damping, compared with glass fiber reinforced has better performance. Therefore, carbon fiber reinforced nylon (CF / PA) composites have developed rapidly in recent years. And for 3D printing using SLS technology is the most suitable technical means to achieve carbon fiber reinforced nylon. TDS for reference Application Our company Xiamen LFT composite plastic Co., Ltd is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) & Long Carbon Fiber Series (LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm in length. The company's continuous infiltration reinforced thermoplastics have passed ISO9001&16949 system certification, and the products have obtained lots of national trademarks and patents.view more

-

LFT PBT long glass fiber reinforced thermoplastic virginal granulesKnown for its dimensional stability, low moisture absorption, high strength, stiffness, and chemical, UV, and thermal resistance.

- Glass Fiber Reinforced PBT applications

- PBT vs PET

- PBT with glass fiber properties

- PBT molding guidelines

- Reinforced thermoplastics market trends

- injection molding materials LFT-G

Tags :

-

LFT PBT long glass fiber reinforced thermoplastic virginal granulesKnown for its dimensional stability, low moisture absorption, high strength, stiffness, and chemical, UV, and thermal resistance.view more

-

LFT Polypropylene PP filling long glass fiber 20%-60% high performance thermoplastic resinPP material Polypropylene, PP for short, is a polymer of propylene by adding polymerization. White waxy material, transparent and light in appearance. Polypropylene is a thermoplastic synthetic resin with excellent properties. It is a colorless translucent thermoplastic lightweight general plastic with chemical resistance, heat resistance, electrical insulation, high strength mechanical properties and good high wear-resisting machining properties. PP-LGF material PP plus glass fiber is by adding glass fiber reinforced PP material, due to the addition of glass fiber, limited the mutual movement between polymer chains of PP plastic, therefore, the shrinkage rate of glass fiber reinforced PP (PP plus glass fiber) decreases, rigidity, impact resistance, tensile strength, compression strength, bending strength and flame retardant are improved. The mechanical properties of PP plus glass fiber specifically, tensile strength reached 65MPa--90MPa, bending strength reached 70MPa--20MPa, bending modulus reached 3000MPa--4500MPa, such mechanical strength can be completely comparable with ABS and enhanced ABS products, and more heat resistant. Generally, the heat resistance temperature of ABS and reinforced ABS is between 80℃--98℃, and the heat resistance temperature of glass fiber reinforced PP material can reach 135℃--145℃, and even 150 degrees can withstand more than 1000 hours. Compared with SGF(Short Glass Fiber) TDS for reference only Application of PP-Long glass fiber PP filling long glass fiber material, can be used to make refrigerators, air conditioning and other refrigeration machines in the axial flow fan and fan. In addition, it can also be used to manufacture the inner drum of high speed washing machine, wave wheel, belt wheel to adapt to its high mechanical performance requirements, used for rice cooker base and handle, electronic microwave oven and other places with high temperature resistance requirements, generally speaking, most glass fiber reinforced PP material is used in the structural parts of the product, is a kind of structural engineering materials. Cases Washing machine parts Automobile front end parts Scooter parts Frequently asked questions 1. Does long glass fiber injection have special requirements for injection molding machines and molds? A. There are certainly requirements. Especially from the product design structure, as well as the injection molding machine screw nozzle and mold structure injection molding process must consider the requirements of long fiber. 2. After long glass fiber reinforced, glass fiber can enter the surface of the plastic product during injection molding process, so that the surface of the product become rough and floating fiber. How to make the surface of the material smoothly? A. During injection molding process need to ensure that the plastic particles are well plasticized and dispersed, also ensure that the drying of plastic particles have no moisture removal, mold temperature adjustment to the appropriate temperature, mold surface is polished in place. 3. Can products with appearance requirements be made of long-fiber materials? A. The main feature of LFT-G thermoplastic long glass fiber and long carbon is to show the mechanical properties. If the customer has bright or other requirements for the appearance of the product, it needs to be evaluated in combination with specific products,

- long fiber compounds pp

- pp lgf40

- long glass fiber polypropylene

- long fiber composite PP granules

- PP LFT Compounds polymers

Tags :

-

Xiamen LFT Polypropylene filled Long Carbon Fiber modified plastic high strength and rigidityCarbon Fiber Reinforced Plastic Carbon fiber reinforced plastic composite (CFRP) is a lightweight, strong material that can be used to make a wide range of products used in everyday life. It is a term used to describe fiber reinforced composites with carbon fiber as the main structural component. Note that the "P" in CFRP can also stand for "plastic" rather than "polymer." Typically, CFRP composites use thermosetting resins such as epoxy, polyester, or vinyl esters. Despite the use of thermoplastic resins in CFRP composites, "carbon fiber reinforced thermoplastic composites" often uses its own acronym, CFRTP composites. LFT-G focuses on LFT&LFRT. Long Glass Fiber Series (LGF) & Long Carbon Fiber Series. Compared with Short Carbon Fiber, Long Carbon Fiber has more excellent performance in mechanical properties. It is more suitable for large products and structural parts. It has 1-3 times higher (toughness) than Short Carbon Fiber, and the tensile strength(strength and rigidity) is increased by 0.5-1 times. Properties of PP CF Composites Composites reinforced with carbon fiber are different from other FRP composites that use traditional materials such as glass fiber or arylon fiber. Advantages of CFRP composites include: Light weight: Conventional fiberglass reinforced composites using continuous fiberglass and 70% fiberglass (glass weight/gross weight) typically have a density of 0.065 lb/cubic inch. A CFRP composite with the same 70% fiber weight might typically have a density of 0.055 lb/cubic inch. Increased strength: Carbon fiber composites not only weigh less, but CFRP composites are stronger and stiffer per unit weight. This is true when comparing carbon fiber composites to glass fibers, and even more so when comparing metals. For example, when comparing steel to CFRP composites, a good rule of thumb is that a carbon fiber structure of the same strength typically weighs 1/5 as steel. You can imagine why car companies are looking into using carbon fiber instead of steel. When comparing CFRP composites to aluminum (one of the lightest metals used), the standard assumption is that an aluminum structure of the same strength might weigh 1.5 times as much as a carbon fiber structure. Of course, there are many variables that can change this comparison. Grades and qualities of materials may vary, and for composites, the manufacturing process, fiber structure and quality need to be considered. Application of PP-LCF Long Carbon Fiber as the reinforcement material of CFRP, its proportion is only 1/4 of iron, specific strength is 10 times that of iron, elastic modulus is 7 times that of iron, carbon fiber excellent physical properties are played in various fields from sports goods to aircraft. Details of product Number Length Color Sample Package Delivery time Port of Loading Freight PP-NA-LCF30 5-25mm Original color (can be customized) Available 20kg a bag 7-15days after shipment Xiamen Port Depending on your destination Related products PA6-LCF PA66-LCF About Xiamen LFT Composite plastic Co., Ltd. A new material enterprise that develops and produces its own brand of LFT long glass fiber and long carbon fiber. It fills the blank of domestic high-end long carbon fiber LFT materials, and is more customized and shortened the production cycle compared with foreign companies. In addition, our company has sales and service offices in Istanbul, Zhejiang, Jiangsu, Guangzhou, etc. It can more easily to understand customer needs and has more convenient after sale.

- Long fiber reinforced thermoplastics

- Modified materials of long carbon fiber

- Polymer composites automotive parts

- The modified PP high performance

- Long carbon fiber filling plastic PP car part use

- LFT-G brand materials pp polymer chemical resistance

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文