-

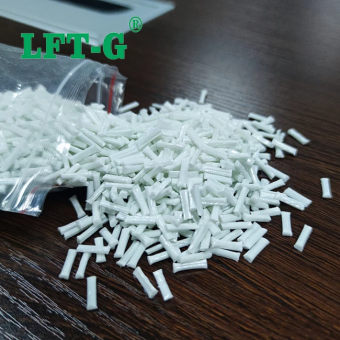

LFT polyphenylene sulfide Long Fiber Thermoplastic PPS LGF40% CompositeProduct Name: Long glass fiber 40% Fill PPS Length:About 12mm Applicaiton:Auto parts, energy components and other plastic partsview more

-

Xiamen LFT Nylon Polyamide 6 excellent heat resistant properties Long glass fiber Filled PelletsWhat is Polyamide? Polyamide (PA) Polyamide, which is also known by the trade name, Nylon, has excellent heat resistant properties, especially when combined with additives and filler materials. In addition to this, Nylon is very resistant to abrasion. Xiamen LFT offers a wide range of temperature-resistant nylons with many different filler materials. If you are not sure which PA material is suitable for you, please tell us your needs and our team will provide you with technical support free of charge. What is Polyamide 6? Nylon 6 or PA 6 Has a semi-crystalline structure and is used for nonwoven fabrics Ductility and Abrasion resistance What Are the Advantages of Nylon 6? The main advantages of nylon 6 are its stiffness and resistance to abrasion. Moreover, this material has excellent impact strength, wear resistance, and electrical insulating properties. Nylon 6 is a highly elastic and fatigue-resistant material, meaning it will return to its original proportions after being distorted by tension. This polyamide is non-toxic and can be combined with glass or carbon fibers to increase performance. The absorption capacity of the material grows in direct proportion to the quantity of moisture it absorbs. The high affinity of nylon 6 for some dyestuffs allows for more dyeing diversity, with the potential for brighter, deeper patterns. Can Nylon 6 Be Used in Plastic Injection Molding? Yes, Nylon 6 is a suitable material for injection molding. The resulting molded nylon parts possess great strength, as well as chemical and temperature resistance. When molding nylon 6, the material is sometimes injected with a specified amount of glass fibers (usually between 20% and 60%) to boost its tensile strength. Glass fibers improve stiffness. Moreover, since UV radiation can be harmful to nylon, a UV stabilizer is frequently added to the material before injection molding to decrease the possible degradation of the item with time. Is Nylon 6 a Copolymer? No, nylon 6 is not a copolymer. The clue is in the name “nylon 6” in which the 6 represents the single repeating monomer which has 6 carbon atoms. Nylon 6 is made through the polymerization of a monomer named caprolactam. Nylon 6 is not to be confused with nylon 6,6 which is made of two repeating monomers hexamethylenediamine and adipic acid; this makes it a copolymer. Two other nylons are also copolymers; they are nylon 6,12 and nylon 4,6. Why filling Long Glass Fiber into Polyamide 6? Long glass fiber reinforced composites can solve your problems when other methods of reinforced plastics do not provide the performance you need or if you want to replace metal with plastic. Long glass fiber reinforced composites can cost-effectively reduce the cost of goods and effectively improve the mechanical properties of engineering polymer .Long fibers can be uniformly distributed inside the product to form a network skeleton, thus improving the mechanical properties of the material product. LFT is the product name for a family of long fiber reinforced thermoplastic materials for Injection Molding, Compression Molding and Extrusion applications. These materials differ from standard thermoplastic compounds in the length of the fiberglass in the pellets. Retention of fiber length in the finished part is key to the performance of LFT. The fiberglass is continuous within the pellet and offers incredible properties and performance when molded correctly. What is the application of PA6-LGF? Other PA Plastic you may interested: PA66-LGF PA12-LGF About Xiamen LFT

- LFT Long fibre glass reinforced thermoplastic resin

- Polyamide 6 PA plastic

- High strength for car parts auto

- raw materials made in China good price

- high-performing polymer

- washing machine drum parts good appearance

Tags :

-

Xiamen LFT-G High Density Polyethylene Plastic filled long glass fiber reinforced compounds natural colorHDPE-LGF High density polyethylene (HDPE)/ glass fiber (LGF) composites were prepared by twin-screw extrusion mechanism, and the mechanical properties and non-isothermal crystallization behavior of HDPE/LGF composites were studied. The results show that the impact strength of the composite can be improved by MAH-g-POE, and the interface bond between the glass fiber and HDPE is good. The Avrami index (n) of the composite does not change with the cooling rate. Datasheet Application Package Xiamen LFT composite plastic Co.,Ltd Come and find us! We will offer you: 1. LFT & LFRT material technical parameters and leading edge design. 2. Mold front design and recommendations. 3. Provide technical support such as injection molding and extrusion molding.

- HDPE filling lgf20

- lgf hdpe composite materials

- reinforced hdpe plastic resin

- long glass fiber hdpe

- Thermoplastic hdpe lgf

- hdpe resin compounds

Tags :

-

Xiamen LFT-G Polypropylene filling long glass fiber high performance modified plastic 12mmPP-LGF Glass fiber reinforced PP, usually, the tensile strength of PP material is between 20M~30MPa, bending strength is between 25M~50MPa, bending modulus is between 800M~1500MPa. If PP is to be used in engineering structural parts, it must be reinforced with glass fiber. Glass fiber reinforced PP, through glass fiber reinforced PP product mechanical properties can be multiplied or even several times the improvement. Specifically, the tensile strength reaches 65MPa~90MPa, the bending strength reaches 70MPa~120MPa, and the bending modulus reaches 3000MPa~4500MPa. Such mechanical strength can be completely comparable with ABS and enhanced ABS products, and it is more heat resistant. Glass fiber reinforced PP, general ABS and reinforced ABS heat resistance temperature between 80℃~98℃, and glass fiber reinforced PP material heat resistance temperature can reach 135℃~145℃. PP filling modification, adding a certain amount of inorganic minerals in PP, such as talcum powder, calcium carbonate, titanium dioxide, mica, etc., can improve rigidity, improve heat resistance and luster; Filling carbon fiber, boron fiber, glass fiber can improve the tensile strength; Adding flame retardant can improve flame retardant property. Filling antistatic agent, colorant, dispersant, etc. can improve the antistatic property, colorability and fluidity, etc.; Filling nucleating agent can speed up the crystallization speed, increase the crystallization temperature, form more and smaller spherical crystals, thus improving the transparency and impact strength. Therefore, the filler has a significant effect on improving the performance of plastic products, improving the plastic molding processability and reducing the cost. Application As one of the four general plastic materials, PP has excellent comprehensive performance, good chemical stability, better molding performance and relatively low price; But it also has the strength, modulus, hardness is low, low temperature impact resistance strength is poor, forming shrinkage, easy aging and other shortcomings. Therefore, it must be modified so that it can adapt to the demand of the product. The modification of PP material is generally through adding mineral reinforcement toughening, weather resistance modification, glass fiber reinforcement, flame retardant modification and super toughness modification, and each kind of modified PP has a large number of applications in the field of household appliances. Glass fiber reinforced PP, can be used to make refrigerators, air conditioning refrigeration machines such as axial flow fans and cross flow fans. In addition, it can also be used to manufacture the inner drum of high speed washing machine, wave wheel, belt wheel to adapt to its high requirements on mechanical properties, for the rice cooker base and handle, electronic microwave oven and other places with high requirements on temperature resistance. Glass fiber reinforced PP. Ordinary short glass fiber reinforced PP, because the glass fiber contains short, easy warping, low impact strength, easy deformation when heated, long glass fiber can overcome the above defects of short glass fiber, and the product has a better surface, higher temperature, higher impact strength, can be used in refrigerators and kitchen appliances with high heat resistance. Glass fiber reinforced PP is on the basis of the original pure PP, adding glass fiber and other additives, so as to improve the scope of use of materials. Generally speaking, most glass fiber reinforced materials are used in the structural parts of the product, which is a kind of structural engineering materials. Datasheet Cases Xiamen LFT composite plastic Co., Ltd. Xiamen LFT Composite Plastic Co.,LTD was established in 2009, is a brand-name global suppliers of long fiber reinforced thermoplastic materials integrating product research & development(R&D), production and sale marketing. Our LFT products have passed the ISO9001&16949 system certification and have obtained lots of national trademarks and patents, covering the fields of automotive, military parts and firearms, aerospace, new energy, medical equipment, power wind energy, sports equipment, etc.

- long glass fiber polypropylene high performance

- pp injection molding composite

- PP resin compounds LFT GF

- pp lgf lft thermoplastic resin made in China

- lgf filling pp raw materials sample available

- pp industry use lft green materials

Tags :

-

LFT-G modified ABS compounds Long Glass Fiber for automotive partsABS material Acrylonitrile-butadiene styrene (ABS) resin is an opaque amorphous thermoplastic engineering plastic with complex two-phase structure. It is composed of styrene, acrylonitrile and butadiene in different proportions. In the 1970s, it began to be recognized by the public and began to be used. In the 1990s, the market demand grew rapidly. At present, it should be used in domestic and foreign markets, especially in construction, home appliances, automobiles and other industries. ABS-LGF Long glass fiber is widely used in engineering plastics. Reinforced ABS composites are made by adding a certain percentage of glass fiber, with the addition of 30% to 50% glass fiber being the most common. So as to improve the mechanical properties of ABS. Such as tensile properties, bending properties, and the corresponding molding shrinkage rate is not reduced, so that the material will not stress cracking. Advantages: 1. Long glass fiber reinforced, glass fiber is a high temperature resistant material, therefore, the heat resistant temperature of reinforced plastic is much higher than before without glass fiber, especially nylon plastics 2. After long glass fiber reinforcement, due to the addition of long glass fiber, the mutual movement between polymer chains of plastic is limited, therefore, the shrinkage rate of reinforced plastics decreases a lot, and the rigidity is greatly improved. 3. After long glass fiber reinforcement, reinforced plastics will not stress crack, at the same time, the anti-impact performance of plastics is improved a lot. 4. After long glass fiber reinforcement, glass fiber is a high strength material, which also greatly improves the strength of plastic, such as: tensile strength, compression strength, bending strength, improve a lot. 5. Long glass fiber reinforced after, due to the addition of glass fiber and other additives, the combustion performance of reinforced plastics decreased a lot, most of the material can not ignite, is a kind of flame retardant material. Datasheet for reference only Processing flow Cases About Xiamen LFT-G Xiamen LFT composite plastic Co., Ltd. is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series(LGF) & Long Carbon Fiber Series(LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm length. The company's long-fiber continuous infiltration reinforced thermoplastics have passed ISO9001 & 16949 system certification, and the products have obtained lots of national trademarks and patents.

- Modified material lft injection molding

- ABS compounds long glass fiber

- lgf injection mold abs for engineering

- reinforced material abs filling lgf

- ABS-LGF30 thermoplastic resin

- Thermoplastic resin ABS

Tags :

-

Xiamen LFT Thermoplastic Polyurethane TPU Long Glass Fiber filling composite industry productProduct number: TPU-NA-LGF Product fiber specificaion: 20%-60% Product features: High toughness, High toughness, Low water absorption, High dimensional stability, chemical resistance, good product appearance.

- Low water absorption price good

- footwear shoes uses

- Columnar particle safty plastic

- Natural color images sa

- Industrial supplies film automotive

- Sample available tpu 3d printing

Tags :

-

Xiamen LFT Nylon series Polyamide 66 Long Glass Fiber Reinforced Thermoplastic ResinPolyamide, which is also known by the trade name, Nylon, has excellent heat resistant properties, especially when combined with additives and filler materials. In addition to this, Nylon is very resistant to abrasion. Xiamen LFT offers a wide range of temperature-resistant nylons with many different filler materials. About PA66-LGF compounds Nylon 6,6, also written as nylon 6-6, nylon 66, or nylon 6/6, is a more crystalline version of nylon 6. It is also referred to as polyamide 66 or PA 66. It has improved mechanical properties due to its more ordered molecular structure. Nylon 66 for machining has improved temperature resistance and lower rates of water absorption when compared to standard nylon 6. The advantages of nylon 6,6 are that the yield strength is higher than nylon 6 and nylon 610. It has high strength, toughness, rigidity, and low coefficient of friction in a wide temperature range. In addition, it is oil resistant and resistant to chemical reagents and solvents. However, PA66 has strong hygroscopicity and poor dimensional stability, which limits its application. In order to obtain nylon 66 engineering material with higher strength, it should be modified by glass fiber reinforcement. The mechanical properties of long glass fiber reinforced nylon 66 (LGFR-PA66) are obviously better than those of short glass fiber reinforced nylon 66 (SGFR-PA66), and the molding processing performance is also better. It can be molded by various molding methods such as injection molding and compression molding, and complex components can also be formed. Therefore, long glass fiber reinforced nylon 66 can be widely used in building materials, aerospace, electronic devices, furniture and other fields, especially in the automotive industry application market. The production process of long glass fiber reinforced nylon 66 is different from that of short glass fiber reinforced nylon 66. The short glass fiber reinforced nylon 66 particle is chopped under the friction and shearing of screw and barrel, and the short glass fiber reinforced nylon 66 particle is obtained with the length of glass fiber monofilament about 0.5mm. The length of some glass fiber monofilament in the final product is lower than the critical length of reinforcement, and the glass fiber is easy to be extracted from the nylon 66 matrix when the product is stressed. The strength of glass fiber is not fully utilized, and the mechanical properties of the product are not high. Long glass fiber reinforced nylon 66 has better reinforcement effect and dimensional stability, and the rigidity, tensile, bending, impact resistance and fatigue resistance of the manufactured products are better, and the service life is longer. Materials Details Number PA66-NA-LGF Color Natural color or Customized Length 6-25 mm Package 25kg/bag MOQ 25kg Lead time 2-15 days Port of Loading Xiamen Port Trade terms EXW/FOB/CFR/CIF/DDU/DDP About Xiamen LFT Xiamen LFT Composite Plastic Co.,LTD was established in 2009, is a brand-name global suppliers of long fiber reinforced thermoplastic materials integrating product research & developmen (R&D), production and sale marketing. Our LFT products have passed the ISO9001&16949 system certification and have obtained lots of national trademarks and patents, covering the fields of automotive, military parts and firearms, aerospace, new energy, medical equipment, power wind energy, sports equipment, etc. LFT long fiber reinforced thermoplastic engineering materials,compared to ordinary short fiber reinforced thermoplastic materials (fiber length is less than 1-2 mm), the LFT process produces thermoplastic engineering material's fibers in lengths of 5-25 mm. The long fibers are impregnated with the resin through a special mold system to obtain long strips that are fully impregnated with the resin ,and then cut to the length as required. The most used base resin is PP, by PA6, PA66, PPA,PA12,MXD6,PBT,TPU,PPS, ABS,PEEK, etc. Conventional fibers include glass fiber, carbon fiber. Depending on the end use, the finished products can be used for injection molding,extrusion, molding, etc., or directly used for plastic instead of steel and thermoset products.

- PA66 PA 6.6 Enginering materials

- excellent heat resistance with filler

- injection molding products light weight

- car parts toy home applance use

- modified plastic manufacturer can be customized

- can be recylced GFRP GF30

Tags :

-

LFT-G PBT Long Glass Fiber Reinforced Thermoplastic Resin Compounds Pellets EngineeringWhat is PBT? Polydibutyl terephthalate is a crystalline thermoplastic engineering plastic polymerized by dimethyl terephthalate (DMT) and 1,4-butanediol. PBT can also be called thermoplastic polyester plastic, in order to be used by different processing operators, generally how many additives will be added, or mixed with other plastics, with the proportion of additives is different, can manufacture different specifications of products. Due to its special properties, PBT is an ideal material for special applications in electrical engineering and electronics. 1. mechanical properties: high strength, fatigue resistance, dimensional stability, creep is also small (there is little change under high temperature conditions) 2. heat resistance aging: enhanced UL temperature index of 120~140℃(outdoor long-term aging is also very good) 3. solvent resistance: no stress cracking 4. water stability: PBT is not easy to decompose in water 5. insulation performance: excellent (wet, high temperature can also maintain stable electrical performance) What is fiberglass? Glass fiber (formerly known as glassfiber) is an inorganic nonmetallic material with excellent properties. It is made of pyrophylla, quartz sand, limestone, dolomite, borocalcium, boromite and seven ores as raw materials by high-temperature melting, wire drawing, winding, weaving and other processes. The diameter of its monofilament ranges from several microns to more than twenty microns, equivalent to 1/20-1/5 of a hair, and each fiber filament is composed of hundreds or even thousands of monofilament. Fiberglass products are relatively environmentally friendly within the controllable range. PBT has very weak hygroscopic properties. The tensile strength of the non-enhanced PBT is 50MPa, and the tensile strength of the glass fiber reinforced PBT is 170MPa. PBT crystallizes very quickly, so it is easy to bend and deform parts during injection molding due to uneven cooling. The shrinkage rate of general PBT materials is between 1.5% and 2.8%. PBT materials with 30% glass fiber reinforcement shrink between 0.3% and 1.6%. 1. high temperature resistance After testing, when the temperature reaches 300℃, there is no effect on the strength of glass fiber. 2. high tensile strength The tensile strength of glass fiber is 6.3~6.9g/d in the standard state, and 5.4~5.8g/d in the wet state. 3. good electrical insulation Glass fiber has excellent electrical insulation, is a high-level electrical insulation material, and is also used in insulation materials and fire shielding materials. 4. Burn Glass fiber can be melted into glass beads at high temperature, which meets the requirements of fire prevention and control in the construction industry. 5. good sound insulation The combination of glass fiber and gypsum can achieve a good sound insulation effect Why filled PBT with glass fiber? Adding glass fiber to PBT is a common method of PBT enhancement modification. Glass fiber and PBT resin bonding force is good, after adding a certain amount of glass fiber to PBT resin, not only can maintain the original advantages of PBT resin chemical resistance, processability and so on, but also can greatly improve its mechanical properties, and overcome PBT resin notch sensitivity. Impacts of Long Glass Fiber Reinforced PBT Compounds 01Wear resistance PBT has excellent wear resistance and is advantageous where resistance to friction and wear is required. In applications such as mechanical transmission components and bearings, the wear resistance of PBT has been effectively utilized. 02Mechanical properties PBT has excellent mechanical properties after modification. It has high strength and fatigue resistance, good dimensional stability and low creep. Therefore, PBT is often used for parts that need to withstand larger loads and be used for a long time. 03Thermal stability PBT has excellent thermal stability, can maintain its performance under high temperature conditions, and is not prone to thermal decomposition or deformation. This makes PBT an ideal choice for withstanding high-temperature working environments, such as wire connectors and insulating parts in electronic and electrical equipment. 04Flame retardancy PBT has good flame retardant properties after modification and can meet the flame retardant requirements of some special fields. UL94 is a standard for testing the flame retardant properties of materials. The flame retardant grade of PBT engineering plastics can reach UL94 V-0 level, which means that in the flame test, the burning time of the PBT sample is shorter than 10 seconds, and there is no flame retardant during the burning process. dripping phenomenon. This makes PBT molding materials widely used in fields with high requirements for flame retardancy, such as the electronic and electrical industry, providing reliable guarantee for safety performance.

- polybutylene terephthalate

- great mechanical strength and good dimensional

- polymer composites instead metal steel

- Fuel pump connector

- LGF fibre electricity and electronics sector

- Injection molding products high rigidity

Tags :

-

Xiamen LFT MXD6 resin long glass fiber reinforcement polymer compoundsMXD6 resin granules filling long glass fiber compounds pellets factory price

- MXD6 resin polymer thermoplastic

- MXD6 pellets made in China

- MXD6 polymer imdustrial use good price

- plastic raw material MXD6 GF30 glass fiber

- MXD6 granules reinforced plastic

- plastic MXD6 lgf40 sample available

Tags :

-

Xiamen LFT-G Homopolymer Polypropylene reinforced Long Glass Fiber compondsHPP is Homopolymer polypropylene

- Homopolymer Polypropylene HPP GF30

- High impact material polypropylene high

- PP plastic thermoplastic fiberglass

- Sample provide products polypropene

- 25kg/bag PP glass fiber filament

- Environmental friendly plastic

Tags :

-

LFT-G PPA reinforcement filling long glass fiber pellets for car parts large productsPPA plastic PPA is made by polycondensation of aliphatic diamine or diamine with benzene ring-containing diamine or diamine. Compared to aliphatic polyamides, the introduction of a rigid benzene ring in the molecular chain results in a significant increase in mechanical strength and heat resistance, as well as a significant decrease in water absorption. Compared with aromatic polyamides, semi-aromatic polyamides have more flexible aliphatic structures in the molecular weight and lower melting points, which effectively improves the processing performance of aromatic polyamides. Because PPA has both the excellent performance of aromatic polyamide and aliphatic polyamide good molding processability, after years of development has become one of the most important varieties of special engineering plastics, is widely used in electronic and electrical appliances, automotive industry and other fields. PPA filling Long glass fiber compounds Glass fiber reinforced PPA composites are considered to be the best resin for replacing steel with plastic because of their high temperature resistance, high strength and low density. Long glass fiber reinforced PPA composites have better physical and mechanical properties than conventional short-cut fiber reinforced pellets. LCF & SGF Datasheet for reference Applications Customers & Us

- polyphthalamide ppa modified plastic

- reinforced ppa high temperature resistance plastic

- nylon ppa made in China long glass fiber filler

- hard ppa materials high mechanical properties

- safty plastic resin can be recycled ppa

- injection molded ppa good price supplier

Tags :

-

LFT-G Polylactic acid filled long carbon fiber Polymers high performanceWhat is long carbon fiber PLA? While biobased polylactic acid (PLA) thermoplastics are relatively eco-friendly and easy to recycle, composites such as carbon fibre are much stronger. Long carbon fiber reinforced PLA is an outstanding material that is strong, lightweight, has excellent layer bonding and low warpage. It has excellent layer adhesion and low warpage. Long carbon fiber PLA is stronger than other 3D-printed materials. Long carbon fiber filaments are not as strong as other 3D materials, but tougher. The increased rigidity of carbon fiber means increased structural support but reduced overall flexibility. It is slightly more brittle than regular PLA. When printed, the material is a dark glossy color that shimmers slightly under direct light. What is long carbon fiber? Long carbon fiber reinforced composites offer siginificant weight savings and provide optimum strength and stiffness properties in reinforced thermoplastics. The excellent mechanical properties of long carbon fiber reinforced composites make it an ideal replacement for metals. characteristic The fracture strain is moderate (8-10%), so the silk is not brittle, but strong toughness Very high melt strength and viscosity Good dimensional accuracy and stability Easy to handle on many platforms High attractive matte black surface Excellent impact resistance and lightness Application of long carbon fiber PLA materials Long carbon fiber PLA is an ideal material for frame, support, shell, propeller, chemical instrument and so on. Drone makers and RC enthusiasts especially like it, too. Ideal for applications requiring maximum stiffness and strength. Details Number PLA-NA-LCF30 Color Original black (can be customized) Length 12mm (can be customized) MOQ 20kg Package 20kg/bag Sample Available Delivery time 7-15 days after shipment Port of Loading Xiamen Port Exihibition We will offer you: 1. LFT & LFRT material technical parameters and leading edge design 2. Mold front design and recommendations 3. Provide technical support such as injection molding and extrusion molding

- PLA LCF injection molded green materials

- Polylactic acid filling long carbon fiber

- PLA resin lcf replacement of metal

- LFT cpmpounds pla cna be recycled

- lcf reinforced material pla

- Thermoplastic pla lcf CFRP30

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文