What Is Polyphthalamide (PPA)?

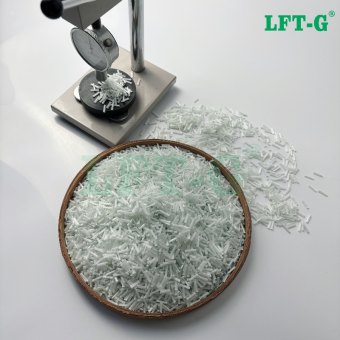

Polyphthalamide is a high-performance resin and member of the nylon family with exceptional thermal, mechanical, and physical properties. It is hygroscopic, opaque, semicrystalline, and can be used in plastic injection molding. Most PPA are filled with glass fiber or carbon fiber to enhance stiffness for high-temperature applications. As a result, PPA is often used in applications in place of metal or higher-priced thermoplastic.

What Are the Uses of Polyphthalamide (PPA)?

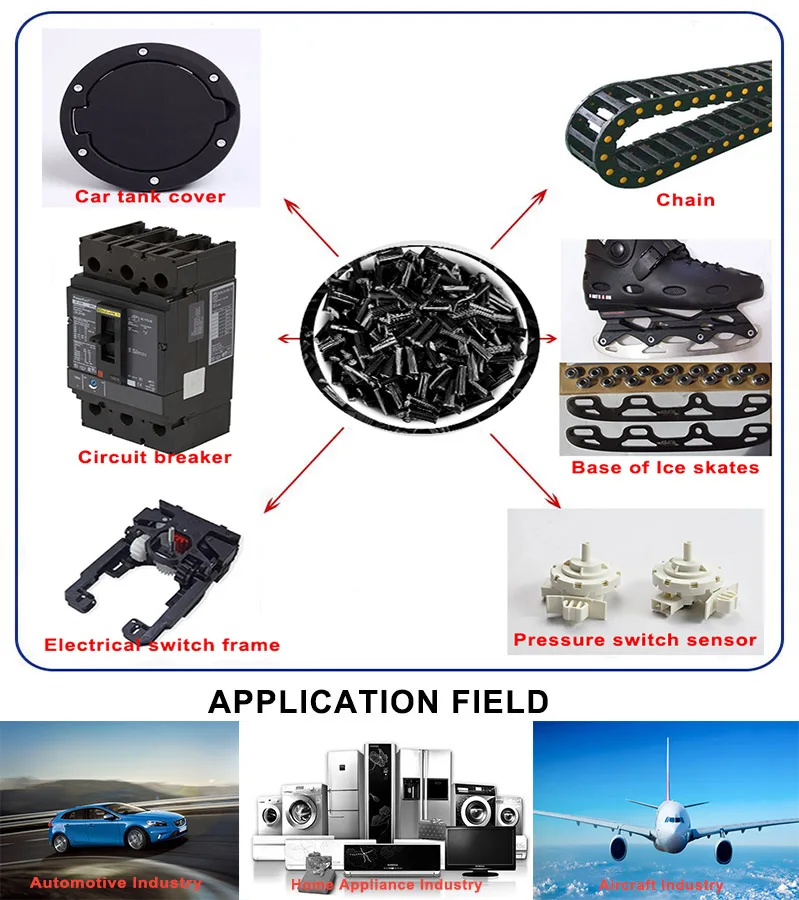

Polyphthalamide has many uses. It is used for electronics and electrical, automotive, cables & wires, and many other applications.

Polyphthalamide is used chiefly as an alternative for several metal components in the industries such as automotive and others. PPA can be used for fuel & coolant lines, motor bobbin parts, pump wear rings, fuel line connectors, fuel cut-off valves, water heater manifolds, fuel modules, thermostat housings, coolant pumps, air coolers, and LED headlights.PPA enables the creation of automobile components with better mechanical strength and decreased overall vehicle weight. As a result, the use of PPA helps to lower fuel consumption.

PPA is also used for multiple electronic applications, as the high melting point of PPA allows SMD parts molded from PPA to be assembled using a lead-free soldering process. PPAs are also utilized for USB-C connectors, cable & wire protection, and LED mounts.

Other uses for PPA-based resins include gas pipes and supply lines for the oil industry.

What Are the Advantages of Polyphthalamide (PPA) in Plastic Injection Molding?

The advantages of PPA in plastic injection molding are as follows:

Very high stiffness and strength

Good heat, chemical, and fatigue resistance

Can resist infrared soldering environments

Low water absorption and relatively low moisture

Very low creep tendency

Good dimensional stability

Advantages

Excellent quality. As replacement of metal and steel.

Own-factory. 500-800 tons of production per month.

Customization. From length to color or additives.

Self laboratory. Provide TDS and COA for every batch.

Fast shipping. Fast shipping to all capital cities or ports.

Favorable price. Free to get price.

Experienced team. With over 20 years experience expert team to provide assistance.

Full service. Through product discussion, performance analysis, composite selection, composite pellet production, after-sales tracking to injection molding techniques.

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文