item no.:

HPP-NA-LGF30Payment:

T/T or L/C (other payment ways also can be diproduct origin:

Xiamen, ChinaColor:

Original color (also can be customized)shipping port:

Xiamen, ChinaHPP material

It is made by polymerization of a single propylene monomer. The molecular chain does not contain ethylene monomer, so the regularity of the molecular chain is very high, so the crystallinity of the material is high and the impact performance is poor.

In order to improve the brittleness of PP-H, fiber modification is used to improve the properties of PP-H.

Advantages: Good strength.

Disadvantages: poor impact resistance (brittle), poor toughness, poor dimensional stability, easy aging, long-term heat resistance and stability performance.

HPP-LGF material

1. Long glass fiber belongs to high temperature resistant material, therefore, the heat resistance temperature of glass fiber reinforced PP is much higher than before without long glass fiber.

2. After adding long glass fiber, the mutual movement between polymer chains of plastic is limited, therefore, the shrinkage rate of glass fiber reinforced plastics decreases a lot, and the rigidity is greatly improved.

3. After long glass fiber reinforcement, PP plastic will not stress cracking, anti-impact performance improved a lot.

4. Long glass fiber is a high strength material, which also greatly improve the strength of PP, such as: tensile strength, compression strength, bending strength, improve a lot.

5. After adding long glass fiber, the combustion performance of PP plastic decreases a lot, and has a certain flame retardant effect.

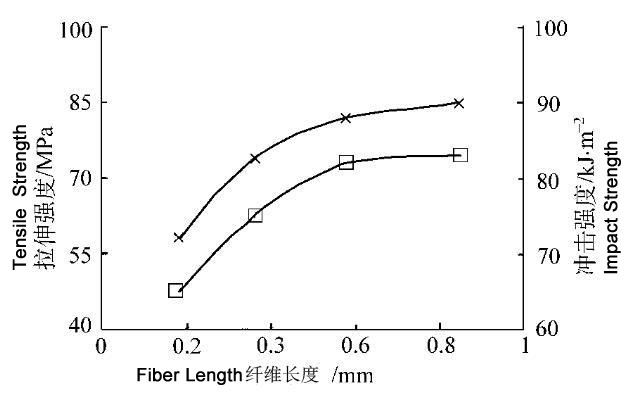

Short glass fiber (SGF) VS Long glass fiber (LGF)

Compared with the short fiber, long fiber has more excellent performance in mechanical properties. It is more suitable for large products and structural parts. It has 1-3 times higher (toughness) than short fiber, and the tensile strength (strength and rigidity) is increased by 0.5-1 times.

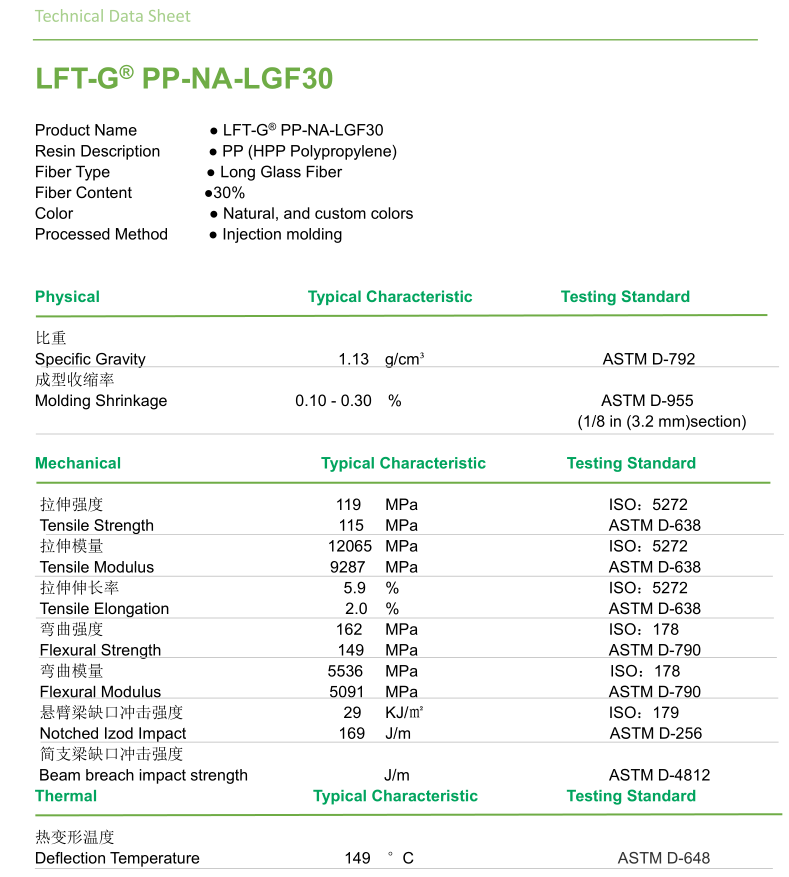

Datasheet for reference

Application

Why choose Long glass fiber compounds?

Long glass fiber reinforced composites can solve your problems when other methods of reinforced plastics do not provide the performance you need or if you want to replace metal with plastic. Long glass fiber reinforced composites can cost-effectively reduce the cost of goods and effectively improve the mechanical properties of engineering polymers, and increase the durability by forming long fibers to form a long-fiber-reinforced internal skeleton network. Performance is preserved in a wide range of environments.

Xiamen LFT composite plastic Co., Ltd

Xiamen LFT composite plastic Co., Ltd is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) & Long Carbon Fiber Series (LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm in length. The company's continuous infiltration reinforced thermoplastics have passed ISO9001&16949 system certification, and the products have obtained lots of national trademarks and patents.