-

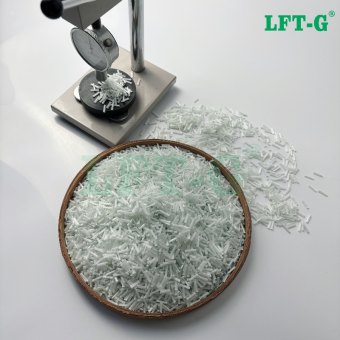

LFT-G xiamen ABS self-factory LGF filling light parts 10-12mmWhat is the modified plastic? Modified plastics are materials with uniform appearance obtained by filling, toughening, reinforcing, blending, alloying and other technical means, with primary form resin as the main component, and additives or other resins that can improve the performance of the resin in mechanics, rheology, combustion, electro-thermal, photomagnetic and other aspects as the auxiliary component. In recent years, the scale of modified plastics industry continues to expand. Modified plastics is a symbol of high-tech, high-performance and high-grade in plastic products, and is widely used in many fields such as aerospace, automobile manufacturing, household appliances, etc., of which the proportion of usage in the automobile field is more than 19%, second only to the home appliance industry, which has the highest usage. In recent years, the use of modified plastics in automobiles has been rising year by year, and the amount of modified plastics used in a single car has become a symbol of the level of automobile design and manufacturing. Divided from the varieties, the amount of plastic varieties are polypropylene (PP), polyamide (PA), acrylonitrile-butadiene-styrene plastics (ABS)), etc., especially PP, PA, ABS, the most abundant automotive modification. From the application point of view, modified plastics are widely used in automotive interior and exterior parts, structural parts and functional parts. Among them, the interior parts are center console, dashboard, decorative panels; exterior parts are air grille, bumper and decorative parts; structural parts are front-end frame, column skeleton; functional parts are lamps, intake manifolds, fuel tanks, etc. are modified plastics used in a large number of automotive parts. What is the Long glass fiber compounds? Glass fiber reinforced plastic is based on the original pure plastic, adding glass fibers and other additives, so as to improve the scope of use of the material. Generally speaking, most of the glass fiber reinforced materials are used in the structural parts of the products, which is a kind of structural engineering materials, such as: PP, ABS, PA66, PA6, PC, POM, PPO, PET, PBT, PPS and so on. Advantages After glass fiber reinforcement, glass fiber is a high temperature resistant material, therefore, the heat-resistant temperature of reinforced plastics is much higher than before without glass fiber, especially nylon plastics. After glass fiber reinforcement, due to the addition of glass fiber, it restricts the mutual movement of the polymer chain of the plastic, therefore, the shrinkage of the reinforced plastic decreases a lot and the rigidity is greatly improved. After glass fiber reinforced, the reinforced plastic will not stress cracking, at the same time, the impact resistance of the plastic improves a lot. After the glass fiber reinforcement, the glass fiber is a high strength material, which also greatly improves the strength of the plastic, such as: tensile strength, compression strength, bending strength, improve a lot. After glass fiber reinforcement, due to the addition of glass fiber and other additives, the combustion performance of the reinforced plastics decreases a lot, most of the materials can not be ignited, it is a kind of flame-retardant material.

- ABS polymers pellets injection molding

- long fibre reinforced thermoplastics

- pellets abs free samples recycled

- extrusion molded low warpage high mechanical properties

- abs injection instead metal high quality

- hot sell best price ABS materials

Tags :

-

Xiamen LFT ABS-LGF Long Glass Fiber Reinforced Thermoplastic Resin PolymersWhat is the modified plastic? Modified plastics are materials with uniform appearance obtained by filling, toughening, reinforcing, blending, alloying and other technical means, with primary form resin as the main component, and additives or other resins that can improve the performance of the resin in mechanics, rheology, combustion, electro-thermal, photomagnetic and other aspects as the auxiliary component. In recent years, the scale of modified plastics industry continues to expand. Modified plastics is a symbol of high-tech, high-performance and high-grade in plastic products, and is widely used in many fields such as aerospace, automobile manufacturing, household appliances, etc., of which the proportion of usage in the automobile field is more than 19%, second only to the home appliance industry, which has the highest usage. In recent years, the use of modified plastics in automobiles has been rising year by year, and the amount of modified plastics used in a single car has become a symbol of the level of automobile design and manufacturing. Divided from the varieties, the amount of plastic varieties are polypropylene (PP), polyamide (PA), acrylonitrile-butadiene-styrene plastics (ABS)), etc., especially PP, PA, ABS, the most abundant automotive modification. From the application point of view, modified plastics are widely used in automotive interior and exterior parts, structural parts and functional parts. Among them, the interior parts are center console, dashboard, decorative panels; exterior parts are air grille, bumper and decorative parts; structural parts are front-end frame, column skeleton; functional parts are lamps, intake manifolds, fuel tanks, etc. are modified plastics used in a large number of automotive parts. What is the Long glass fiber compounds? Glass fiber reinforced plastic is based on the original pure plastic, adding glass fibers and other additives, so as to improve the scope of use of the material. Generally speaking, most of the glass fiber reinforced materials are used in the structural parts of the products, which is a kind of structural engineering materials, such as: PP, ABS, PA66, PA6, PC, POM, PPO, PET, PBT, PPS and so on. Advantages After glass fiber reinforcement, glass fiber is a high temperature resistant material, therefore, the heat-resistant temperature of reinforced plastics is much higher than before without glass fiber, especially nylon plastics. After glass fiber reinforcement, due to the addition of glass fiber, it restricts the mutual movement of the polymer chain of the plastic, therefore, the shrinkage of the reinforced plastic decreases a lot and the rigidity is greatly improved. After glass fiber reinforced, the reinforced plastic will not stress cracking, at the same time, the impact resistance of the plastic improves a lot. After the glass fiber reinforcement, the glass fiber is a high strength material, which also greatly improves the strength of the plastic, such as: tensile strength, compression strength, bending strength, improve a lot. After glass fiber reinforcement, due to the addition of glass fiber and other additives, the combustion performance of the reinforced plastics decreases a lot, most of the materials can not be ignited, it is a kind of flame-retardant material.

- long fibre reinforcement Acrylonitrile Butadiene Styrene

- abs free samples can be recycled

- low warping high mechanical properties

- abs instead metal plastic high quality

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文