item no.:

HPP-NA-LGFPayment:

Discussedproduct origin:

ChinaColor:

Natural color or Customizedshipping port:

XiamenLead Time:

2-10 working days

Product Details

Which is Better, Homopolymer or Copolymer?

It depends. Neither homopolymer nor copolymer is better than the other. It will depend on the application as to which is more desirable. Homopolymers are better suited to high-strength and high-hardness applications, whereas copolymers are suited for corrosion resistance and high operating temperatures. Although a raw homopolymer has better mechanical properties, copolymers have better mechanical properties when reinforced with glass over glass-reinforced homopolymer. This is because copolymers are better suited to adhering to fibers.

Polypropylene, also known as PP or polypropene, is a polyolefin or saturated polymer. It is a low-density thermoplastic with good resistance to heat. Other characteristics of PP include: chemical resistance, elasticity, toughness, fatigue resistance, and electrical insulation capability.

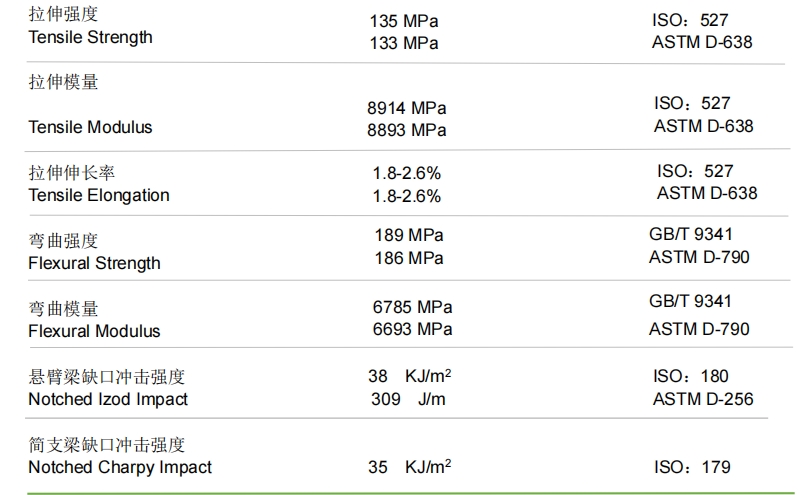

Homopolymer PP with 40% LGF

- What are the Different applications of Homopolymer and Copolymer Polypropylene?

The applications of copolymer long glass fiber reinforced polypropylene (PP) and homopolymer long glass fiber reinforced PP differ mainly in terms of material properties and performance characteristics.

1. Homopolymer Long Glass Fiber Reinforced PP:

- Applications: Typically used in automotive, power tools, and industrial machinery where high strength, impact resistance, and dimensional stability are essential. It is especially suitable for parts that need to withstand heavy mechanical stress and higher temperatures.

- Characteristics: Offers superior rigidity, tensile strength, and heat resistance, but is more brittle compared to copolymer PP.

2. Copolymer Long Glass Fiber Reinforced PP:

- Applications: Ideal for applications that require improved impact resistance and better low-temperature performance. It is often used in consumer products, packaging, and automotive interior components.

- Characteristics: Provides better toughness, flexibility, and resistance to cracking under stress. It performs better at lower temperatures and has enhanced resistance to stress-cracking compared to homopolymer PP.

While both materials are used in high-performance applications, homopolymer PP is better suited for high-strength, structural applications, whereas copolymer PP is preferred when impact resistance, toughness, and flexibility are more critical.

Company Advantages

Excellent quality. As replacement of metal and steel.

Own-factory. 500-800 tons of production per month.

Customization. From length to color or additives.

Self laboratory. Provide TDS and COA for every batch.

Fast shipping. Fast shipping to all capital cities or ports.

Favorable price. Free to get price.

Experienced team. With over 20 years experience expert team to provide assistance.

Full service. Through product discussion, performance analysis, composite selection, composite pellet production, after-sales tracking to injection molding techniques.

FAQ

Q. Under what circumstances can long fiber replace short fiber? What are the common alternative materials?

A: Traditional staple fiber materials can be replaced with long glass fiber and long carbon fiber LFT materials in the case of customers whose mechanical properties cannot be met or where higher metal substitutes are desired. For example, PP long glass fiber is often replacing nylon reinforced glass fiber, and nylon long glass fiber is replacing PPS staple fiber material, etc.

Q. Are long fiber reinforced composites suitable for other processes besides injection molding?

A: In addition to injection molding, LFT long glass fiber and long carbon fiber can also be used for extrusion of sheets, profiles, pipes and molding, among which injection molding is the most common.

Q. At present, do you have any clients who use LFT products to replace metal alloys? What are the specifics?

A: Long glass fiber and long carbon fiber can replace metal products, but need to evaluate the products requirements, there are more successful cases in replacing aluminum and iron products. The tensile strength of mechanical properties of LFT long glass fiber and long carbon fiber exceeds 200MPa, from which it can be a good substitute for aluminum products, and the impact strength is also superior to aluminum products.

Talk to an expert now

Email: sales02@lfrtplastic.com

WhatsApp: +86 139 5009 5727