Categories

new blog

After all, they may be used in rugged products and subsystem components, such as bearings made of alloys such as steel and bronze. Or they simply don't think plastic can handle harsh applications or extreme environmental conditions.

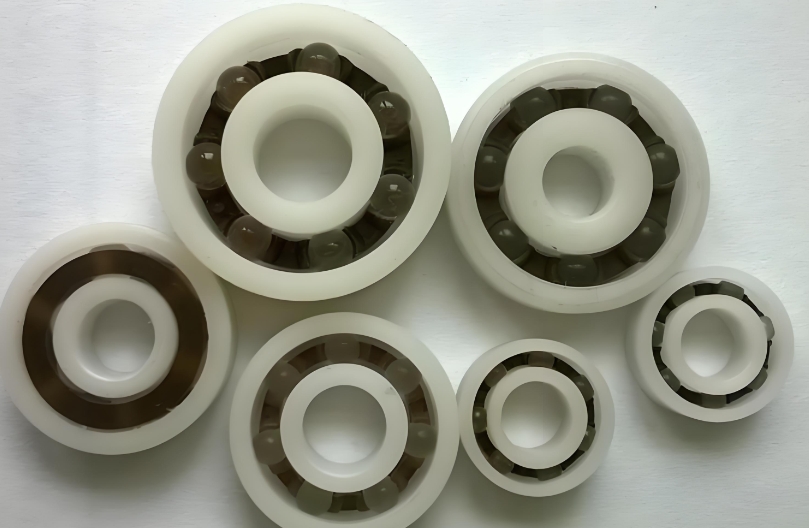

But the fact is that modern plastic bearings (especially plastic ball bearings) can withstand extreme temperatures, heavy loads and high speeds. However, it is important to understand the advantages and disadvantages of the available options.

Self-lubricating polymer bearings contain solid lubricants embedded in tiny chambers of millions of fiber-reinforced materials. During operation, bearings transfer lubricants to the shaft to help reduce the coefficient of friction (CoF).

Unlike sintered bronze bushings, engineering plastic bearings release solid lubricants once the bearing or shaft begins to move. The fiber reinforced material in the bearing can withstand any high force or edge load. Plastic bearings are also available for many different shaft types.

Why use plastic bearings?

5 advantages of plastic ball bearings in general industrial use

1. Minimal maintenance

Plastic bearings can replace bronze, metal supports and custom injection moulded bearings in almost any application. Their resistance to dirt, dust and chemicals makes plastic bearings an "install and forget" solution.

2. Save costs

Plastic bearings can typically reduce costs by up to 25%. With their high wear resistance and low coefficient of friction, plastic bearings can often replace more expensive alternatives in a variety of applications.

3. No messy lubricants

Self-lubricating bearings transfer lubricants to the shaft to help reduce the coefficient of friction and are not affected by dirt, dust or other contaminants.

4. Consistent Coefficient of Friction (CoF)

Plastic bearings are designed to maintain a consistently low CoF throughout the life of the bearing. Plastic bearings typically last longer than metal-supported bearings, which can be scratched and increase CoF.

5. Corrosion resistance and chemical resistance

Plastic bearings can be used for flushing applications, salt water and harsh chemicals without compromising performance. Water can even be seen as a lubricant for plastic bearings.

Application of plastic bearing in food industry

Plastic bearings are particularly suitable for food industry applications. Compared to steel bearings, plastic bearings offer better hygiene, less maintenance and higher productivity.

From single machines to complete product lines, plastic bearings are an excellent alternative to steel bearings on workhorses in the food industry (conveyor systems, hoppers, mixers, filling machines, packaging arms, bottling equipment, etc.).

Why use plastic bearings in food processing and production industries?

1. Hygiene

Different types of plastic bearings comply with USDA, FDA, NSF and 3-A health standards. These different certifications indicate that bearings are safe for use in a variety of food applications and can eliminate food contamination. Steel bearings are not as hygienic as plastic ones.

2. Temperature tolerance

Many plastic bearing compounds operate easily in the temperature range from freezing to 500°F, making them ideal for a variety of food processing applications. In general, metals have a limited temperature range or require expensive, specialized high-temperature food grade lubricants.

3. Fight swelling

Many plastic bearings have a relatively low moisture absorption rate (from food ingredients or wet processing environments). Steel bearings can corrode or lose lubrication from constant cleaning, which can cause the production line to jam. For the same reason, even higher-cost stainless steel bearings can fail.

4. Strength and durability

Plastic bearings are designed for long-term use and have a much longer service life than steel bearings, allowing food processors to reduce replacement costs on the production line.

5. Low maintenance

Plastic bearings use self-lubricating design, no manual lubrication, can extend the bearing life.

Contact us for more technical assistance.

Email: sale02@lfrtplastic.com

WhatsApp: (+86) 139 5009 5727

Ms. Wallis Wan