new blog

1

History of fiberglass skis

According to the International Ski History Association (ISHA), the world's first alpine ski made of fiberglass composite was invented by engineers Fred Langendorf and Art Molnar and was born in Montreal, Canada, registered under the trade name Toni Sailer.

Three years later, Bill and Don Kirschner founded K2 Sports and began producing their own brand of fiberglass composite skiing. In 1967, Art Molnar joined the K2 movement and developed fiberglass composite skis with foam cores. By 1968, fiberglass composites replaced wood and aluminum as the most common ski material used for recreational skiing. In 1970, fiberglass composites entered the field of cross-country skiing.

In the 1970s, the ski industry optimized and improved the design of composite materials. The use of glass fiber prepreg can improve production efficiency, but it is very expensive. S-grade glass replaces E-grade glass with the material used in the wet lamination process. At the same time, a small amount of kevlar aramid, carbon fiber, ceramic fiber and other high-strength materials are mixed in the glass fiber to improve the overall strength, elasticity, impact resistance and so on.

Biri is the oldest Nordic ski brand in existence, founded by the Norwegian company Madison and acquired by K2 Sports in 1988. From 1906, Madus worked on the design of Nordic skis, and in 1974 began producing fiberglass composite skis. In 1979, Madhesh introduced the design concept of the double torque box, which set the design standard for most snowboards in the world.

2

The application of glass fiber in skis

Fiberglass is commonly used in the construction of skis to enhance their strength, stiffness and durability. The following are common areas where fiberglass is used on skis:

1) Board core enhancement

Fiberglass can be embedded into the ski's wood core to increase overall strength and stiffness. This application can improve the responsiveness and stability of the ski.

2) Bottom of the board

Fiberglass is usually coated on the bottom of skis to increase the wear resistance and sliding performance of the bottom plate. This coating reduces friction and increases the speed of skis on snow.

3) Edge enhancement

The edges of some skis may contain fiberglass reinforcement to improve the edge's impact resistance and wear resistance. This helps protect the edges and extend the life of the ski.

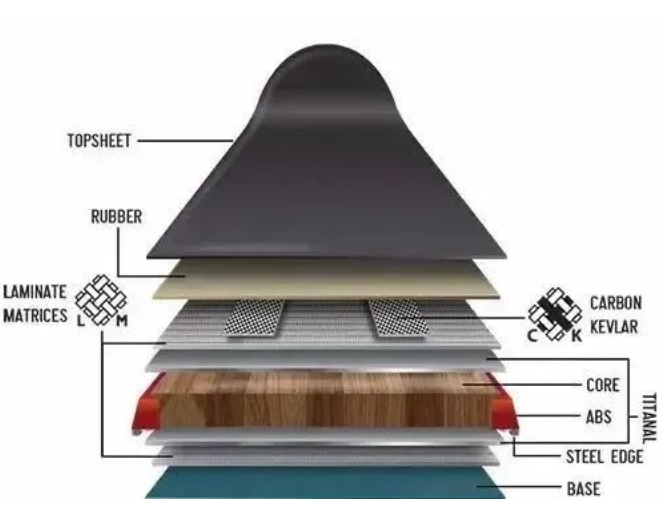

4) Composite material layer

Fiberglass is often used with other composite materials, such as carbon fiber, to make up the different layers of the ski. This combination can adjust the performance of the ski to make it lighter, stronger, more flexible, etc.

5) Binding

Fiberglass reinforced plastic or composite materials may be used in the binding system of some skis to improve the stability and durability of the binding system.

The use of fiberglass helps to make the skis lighter while increasing the strength of the overall structure. This provides better handling and longer service life, allowing skiers to better adapt to a variety of snow conditions and terrain.