Homopolymer Long Glass fiber Reinforced Polypropylene PP;Polypropylene homopolymer long glass fiber is polymerized from a single propylene monomer, with high crystallinity, good mechanical strength and heat resistance.

-

Xiamen LFT long glass fiber reinforced PP Polypropylene materials injectionglass reinforced PP Polypropylene materials polymer long glass fiber 30% injection for car parts,washing machine parts.

- Compound plastic materials PP resin

- Polypropylene with long glass fiber

- pp filling glass fiber reinforced thermoplastic

- High strength modified material

- pp lgf lft PP GF30 high rigidity

- long glass fiber reinforced polypropylene

Tags :

-

Xiamen LFT long glass fiber reinforced PP Polypropylene materials injectionglass reinforced PP Polypropylene materials polymer long glass fiber 30% injection for car parts,washing machine parts.view more

-

Xiamen LFT-G Homopolymer Polypropylene reinforced Long Glass Fiber compondsHPP is Homopolymer polypropylene

- Homopolymer Polypropylene HPP GF30

- High impact material polypropylene high

- PP plastic thermoplastic fiberglass

- Sample provide products polypropene

- 25kg/bag PP glass fiber filament

- Environmental friendly plastic

Tags :

-

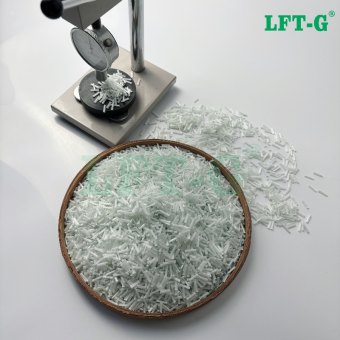

LFT-G Polypropylene PP reinforced long glass fiber high mechanical properites home appliance partsPP filling Long glass fiber PP (polypropylene), as one of the general-purpose plastic materials, has a large production volume and low price, as well as excellent comprehensive performance, good chemical stability, and better molding and processing performance. However, the shortcomings of PP, such as low strength, low service temperature, low hardness, and poor low-temperature impact strength, have seriously limited its application areas. Therefore, engineers by adding glass fiber, calcium carbonate and other reinforcing materials in PP, and when the length of the glass fiber and other lengths exceed the critical size, the mechanical properties are improved by leaps and bounds! Long Glass Fiber Reinforced PP (LFT-PP) is a very typical thermoplastic composite material, which is generally a column of particles with a length of 12 mm to 25 mm and a diameter of about 3 mm. In these particles, the glass fibers have the same length as the particles, the content of glass fibers can vary from 20% to 70%, and the color of the particles can be matched according to customer requirements. PP-LGF advantages 1. longer fiber length, significantly improve the mechanical properties of the products. 2. high strength, good impact resistance, especially suitable for furniture, automotive parts. 3. high creep resistance, good dimensional stability, high precision parts molding. 4. excellent fatigue resistance. 5. better stability in high temperature and humid environment. 6. molding process fiber can be in the molding mold relative movement, fiber damage is small. LGF VS SGF Application Automotive industry: front-end module, door module, gearshift mechanism, electronic gas pedal, instrument panel frame, cooling fan and frame, battery tray, bumper bracket, underbody protection plate, sunroof frame, etc., used to replace reinforced PA or metal materials. Home appliance industry: washing machine drum, washing machine triangle bracket, air conditioner fan, etc., used to replace short glass fiber reinforced PA, ABS or metal materials. Communication, electronics, electrical industry: communication electronics industry, high-precision connectors, ignition components, coil shafts, relay base, microwave oven transformer coil frame / frame, electrical connectors, solenoid valve package, scanner components, etc.. Others: power tool shells, water pump or water meter shells, impellers, bicycle skeletons, skis, ground locomotive pedals, military/civilian safety helmets, safety shoes, such as the head of the package, used to replace the short fiberglass-reinforced PA, PPO and so on. Produce processing Certification About us Xiamen LFT Composite Plastic Co.,LTD was established in 2009, is a brand-name global suppliers of long fiber reinforced thermoplastic materials integrating product research & development(R&D), production and sale marketing. Our LFT products have passed the ISO9001&16949 system certification and have obtained lots of national trademarks and patents, covering the fields of automotive, military parts and firearms, aerospace, new energy, medical equipment, power wind energy, sports equipment, etc.

- LFT-G homopoymer plastic PP

- PP injection molded lgf natural color

- Polypropylene composite plastic modified

- pp gf30 for electrical connector price

- PP pellets lgf 30 polymer

- PP car parts use factory made

Tags :

-

LFT Polypropylene modofied material long glass fiber compounds higher performancePP-LGF Among many composite materials, long glass reinforced polypropylene material (PP-LGF) has gained more popularity for its low price, excellent mechanical properties and environmental friendliness.Compared with short glass fiber reinforced polypropylene material (PP-SGF), PP-LGF has more advantages in strength, stiffness, warpage, fatigue resistance, notch impact strength and dimensional stability, so products produced with PP-LGF can further achieve weight and cost reduction. The length of PP-LGF particles produced by our company is generally 8mm~15mm, in which the content of glass fiber can reach 20%~60%, and the retained length of glass fiber in the particles can reach 1mm~3mm, compared with PP-SGF materials whose retained length of glass fiber is only 0.2mm~0.4mm, PP-LGF can guarantee the following characteristics due to the three-dimensional network structure of its internal fiber. 1. Low density: The use of long glass fiber reinforced composite material instead of steel is an effective way to reduce the weight of the product. 2. High strength: The composite material with modified resin and different length of fiber has high mechanical strength, good rigidity and impact performance, which can replace steel plate to make coverings or structural parts. 3. Low cost: The use of long glass fiber reinforced composite materials instead of metal materials can simplify the design of complex metal parts and achieve the purpose of forming complex parts at one time. 4. Impact resistance: The elastic deformation property of resin makes long glass fiber reinforced composite materials have certain function of absorbing collision energy, and have a large buffering effect on the impact of certain speed. 5. Corrosion resistance: The composite material has strong corrosion resistance, and its corrosion resistance to acid, alkali and salt is better than that of metal. 6. Beauty: most resins have good colorability, and can be made into various colors by adding masterbatch or spraying paint on the surface; through injection and molding, various irregular curvature shapes can be realized. Datasheet for reference Tests Application As the hottest material, our customers have applied the PP-LGF in many fields, like car parts, washing machine parts, etc. Just contact us, and we will provide technical support. About company Xiamen LFT composite plastic Co., Ltd. is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) & Long Carbon Fiber Series (LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm length. The company's long-fiber continuous infiltration reinforced thermoplastics have passed ISO9001&16949 system certification, and the products have obtained lots of national trademarks and patents.

- PP resin lgf gfrp

- good price PP reinforced gf

- instead metal pp plastic long fiebr glass

- thermoplastic PP long fiber

- pp-na-lgf 30 lft white

- glass fiber filling Polypropylene 30%

Tags :

-

Xiamen LFT long glass fiber reinforced PP Polypropylene materials injectionglass reinforced PP Polypropylene materials polymer long glass fiber 30% injection for car parts,washing machine parts.view more

-

Xiamen LFT-G Homopolymer Polypropylene with addition Long Glass Fiber componds higher strengthHPP is Homopolymer polypropyleneview more

-

LFT Homopolymer PP HPP Long Glass Fiber compond cost-effective material lower priceHPP is Homopolymer polypropyleneview more

-

LFT-G Homo PP HPP Long Glass Fiber compond cost-effective material lower priceHPP is Homopolymer polypropyleneview more

-

LFT-G Polypropylene PP modofied material filling long glass fiber compounds higher performance virgin gradePP-LGF Among many composite materials, long glass reinforced polypropylene material (PP-LGF) has gained more popularity for its low price, excellent mechanical properties and environmental friendliness.Compared with short glass fiber reinforced polypropylene material (PP-SGF), PP-LGF has more advantages in strength, stiffness, warpage, fatigue resistance, notch impact strength and dimensional stability, so products produced with PP-LGF can further achieve weight and cost reduction. The length of PP-LGF particles produced by our company is generally 8mm~15mm, in which the content of glass fiber can reach 20%~60%, and the retained length of glass fiber in the particles can reach 1mm~3mm, compared with PP-SGF materials whose retained length of glass fiber is only 0.2mm~0.4mm, PP-LGF can guarantee the following characteristics due to the three-dimensional network structure of its internal fiber. 1. Low density: The use of long glass fiber reinforced composite material instead of steel is an effective way to reduce the weight of the product. 2. High strength: The composite material with modified resin and different length of fiber has high mechanical strength, good rigidity and impact performance, which can replace steel plate to make coverings or structural parts. 3. Low cost: The use of long glass fiber reinforced composite materials instead of metal materials can simplify the design of complex metal parts and achieve the purpose of forming complex parts at one time. 4. Impact resistance: The elastic deformation property of resin makes long glass fiber reinforced composite materials have certain function of absorbing collision energy, and have a large buffering effect on the impact of certain speed. 5. Corrosion resistance: The composite material has strong corrosion resistance, and its corrosion resistance to acid, alkali and salt is better than that of metal. 6. Beauty: most resins have good colorability, and can be made into various colors by adding masterbatch or spraying paint on the surface; through injection and molding, various irregular curvature shapes can be realized. Datasheet for reference Tests Application As the hottest material, our customers have applied the PP-LGF in many fields, like car parts, washing machine parts, etc. Just contact us, and we will provide technical support. About company Xiamen LFT composite plastic Co., Ltd. is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) & Long Carbon Fiber Series (LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm length. The company's long-fiber continuous infiltration reinforced thermoplastics have passed ISO9001&16949 system certification, and the products have obtained lots of national trademarks and patents.view more

-

LFT-G Polypropylene PP modofied material filling long glass fiber compounds higher performance virgin gradePP-LGF Among many composite materials, long glass reinforced polypropylene material (PP-LGF) has gained more popularity for its low price, excellent mechanical properties and environmental friendliness.Compared with short glass fiber reinforced polypropylene material (PP-SGF), PP-LGF has more advantages in strength, stiffness, warpage, fatigue resistance, notch impact strength and dimensional stability, so products produced with PP-LGF can further achieve weight and cost reduction. The length of PP-LGF particles produced by our company is generally 8mm~15mm, in which the content of glass fiber can reach 20%~60%, and the retained length of glass fiber in the particles can reach 1mm~3mm, compared with PP-SGF materials whose retained length of glass fiber is only 0.2mm~0.4mm, PP-LGF can guarantee the following characteristics due to the three-dimensional network structure of its internal fiber. 1. Low density: The use of long glass fiber reinforced composite material instead of steel is an effective way to reduce the weight of the product. 2. High strength: The composite material with modified resin and different length of fiber has high mechanical strength, good rigidity and impact performance, which can replace steel plate to make coverings or structural parts. 3. Low cost: The use of long glass fiber reinforced composite materials instead of metal materials can simplify the design of complex metal parts and achieve the purpose of forming complex parts at one time. 4. Impact resistance: The elastic deformation property of resin makes long glass fiber reinforced composite materials have certain function of absorbing collision energy, and have a large buffering effect on the impact of certain speed. 5. Corrosion resistance: The composite material has strong corrosion resistance, and its corrosion resistance to acid, alkali and salt is better than that of metal. 6. Beauty: most resins have good colorability, and can be made into various colors by adding masterbatch or spraying paint on the surface; through injection and molding, various irregular curvature shapes can be realized. Datasheet for reference Tests Application As the hottest material, our customers have applied the PP-LGF in many fields, like car parts, washing machine parts, etc. Just contact us, and we will provide technical support. About company Xiamen LFT composite plastic Co., Ltd. is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) & Long Carbon Fiber Series (LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm length. The company's long-fiber continuous infiltration reinforced thermoplastics have passed ISO9001&16949 system certification, and the products have obtained lots of national trademarks and patents.view more

-

LFT-G Polypropylene PP reinforced materials long glass fiber filled high mechanical properites for home appliance partsPP filling Long glass fiber PP (polypropylene), as one of the general-purpose plastic materials, has a large production volume and low price, as well as excellent comprehensive performance, good chemical stability, and better molding and processing performance. However, the shortcomings of PP, such as low strength, low service temperature, low hardness, and poor low-temperature impact strength, have seriously limited its application areas. Therefore, engineers by adding glass fiber, calcium carbonate and other reinforcing materials in PP, and when the length of the glass fiber and other lengths exceed the critical size, the mechanical properties are improved by leaps and bounds! Long Glass Fiber Reinforced PP (LFT-PP) is a very typical thermoplastic composite material, which is generally a column of particles with a length of 12 mm to 25 mm and a diameter of about 3 mm. In these particles, the glass fibers have the same length as the particles, the content of glass fibers can vary from 20% to 70%, and the color of the particles can be matched according to customer requirements. PP-LGF advantages 1. longer fiber length, significantly improve the mechanical properties of the products. 2. high strength, good impact resistance, especially suitable for furniture, automotive parts. 3. high creep resistance, good dimensional stability, high precision parts molding. 4. excellent fatigue resistance. 5. better stability in high temperature and humid environment. 6. molding process fiber can be in the molding mold relative movement, fiber damage is small. LGF VS SGF Application Automotive industry: front-end module, door module, gearshift mechanism, electronic gas pedal, instrument panel frame, cooling fan and frame, battery tray, bumper bracket, underbody protection plate, sunroof frame, etc., used to replace reinforced PA or metal materials. Home appliance industry: washing machine drum, washing machine triangle bracket, air conditioner fan, etc., used to replace short glass fiber reinforced PA, ABS or metal materials. Communication, electronics, electrical industry: communication electronics industry, high-precision connectors, ignition components, coil shafts, relay base, microwave oven transformer coil frame / frame, electrical connectors, solenoid valve package, scanner components, etc.. Others: power tool shells, water pump or water meter shells, impellers, bicycle skeletons, skis, ground locomotive pedals, military/civilian safety helmets, safety shoes, such as the head of the package, used to replace the short fiberglass-reinforced PA, PPO and so on. Produce processing Certification About us Xiamen LFT Composite Plastic Co.,LTD was established in 2009, is a brand-name global suppliers of long fiber reinforced thermoplastic materials integrating product research & development(R&D), production and sale marketing. Our LFT products have passed the ISO9001&16949 system certification and have obtained lots of national trademarks and patents, covering the fields of automotive, military parts and firearms, aerospace, new energy, medical equipment, power wind energy, sports equipment, etc.view more

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文