new blog

Polymers are one of the most commonly used and well-known materials of the 21st century. However, pure polymers are not sufficient for use in industries that require great strength and excellent heat resistance. As a result, thermoplastic composites are the preferred materials, and creating these new materials will require overcoming obstacles such as high energy consumption, expensive material costs, reliability, and recyclability.

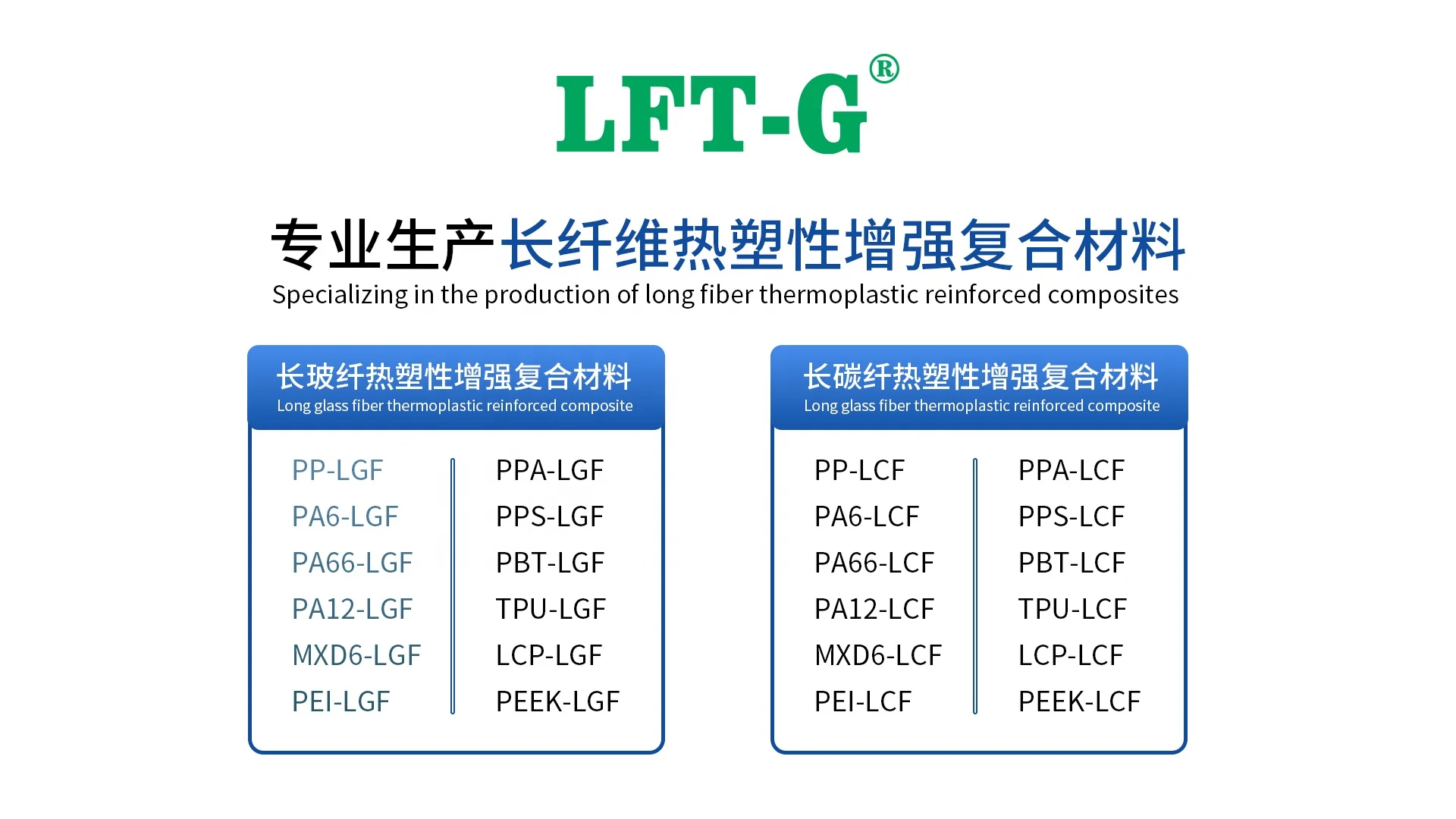

Carbon fiber (CF) has attracted the attention of researchers because of its excellent characteristics such as light weight, high temperature bearing strength, low density, high modulus and good chemical resistance. CF is also a unique material with a high strength-to-weight ratio, low toxicity, recyclable, non-corrosive and good wear resistance. In general, CF has significant electrical, physical, mechanical, and thermal properties. The thermoplastic composite material refers to the thermoplastic polymer (such as polyethylene (PE), polyamide (PA), polyphenylene sulfide (PPS), polyetherimide (PEI), polyether ketone ketone (PEKK) and polyether ether ketone (PEEK) as the matrix, with various continuous/discontinuous fibers (such as carbon fiber, glass fiber, etc.) as the reinforcement of composite materials.

Carbon fiber reinforced thermoplastic composites (CFRTP) have excellent thermal, mechanical and electrical properties, making them widely used in building and construction, maritime, automotive, sporting goods and aircraft applications. Carbon fiber is a promising material for reinforcing polymer matrix.

There are several types of CF materials depending on their precursors/feedstocks, properties, and processing temperatures at the heat treatment stage. CF can also be classified according to discontinuous and continuous fibers (the orientation of the fibers within the matrix) or their length. As a result, many manufacturers produce different types of CF. For example, composites based on discontinuous fibers are used in high-volume applications where properties are required to be almost isotropic. Continuous fiber-based composites, on the other hand, are widely used in low-volume applications where higher mechanical properties are required in one or both directions, such as support beams, impact plates, and containment.

The thermoplastic resin based carbon fiber composites have crystallization and glass transition during processing, while the thermosetting resin based carbon fiber composites have cross-linking and curing reactions. From the process difficulty point of view, the thermoplastic carbon fiber composite is more difficult to infiltrate than the thermoset carbon fiber composite in the preparation process, but at the same time, the advantages are also obvious: it has a short molding cycle, good impact resistance, weldable, can realize secondary molding, and high freedom of structural design.

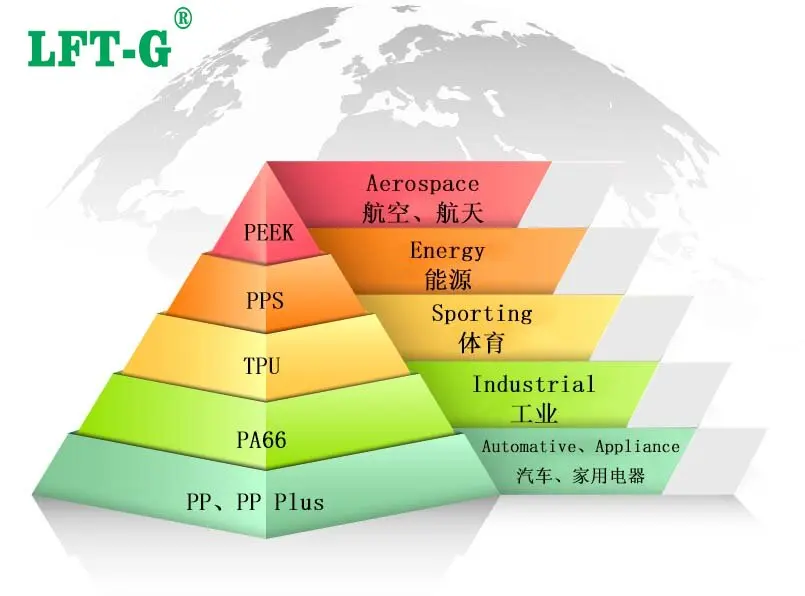

Various parts made of carbon fiber reinforced thermoplastic composite materials have the advantages of low density, high strength, relatively high toughness, recycling and reuse, and have a wide range of application prospects in aerospace, military, high-end machinery, medical and other fields.

Five major carbon fiber reinforced thermoplastic composites

1. carbon fiber reinforced PPS

PPS is a semi-crystalline thermoplastic resin with excellent mechanical properties, chemical erosion resistance, flame retardant and so on. The reinforcement method of carbon fiber also has a very obvious effect on the performance of PPS. In the range below 50%, the larger the volume ratio of carbon fiber in the thermoplastic composite material, the higher the mechanical properties of the composite material.

Carbon fiber reinforced polyphenylene sulfide (PPS) has been widely used in aerospace and military fields in developed countries in Europe, but the domestic application level is still very large compared with it, on the one hand, because of the limitation of the production capacity of raw materials such as PPS resin, on the other hand, it is subject to the application technology of carbon fiber reinforced PPS composite materials. This includes both the ability to prepare composite materials and the ability to develop composite products. Domestically, the domestic carbon fiber reinforced polyphenylene sulfide (CF/PPS) connection sheet has been successfully applied to drones. This is the first time that domestic thermoplastic composite is used as a bearing structural part of UAV, and it is a new attempt and exploration to promote the application of thermoplastic composite in the field of UAV.

In carbon fiber reinforced PI composite materials, carbon fiber is the reinforcement and the main load-bearing structure, while the resin matrix mainly plays the role of connecting the fiber and transferring the load, which can transfer and withstand shear stress, withstand the tensile and compressive load perpendicular to the fiber, and protect the fiber from damage.

When the composite material is subjected to external force, the carbon fiber and the matrix resin as a whole, so that the strain of carbon fiber and the matrix resin is equal, but because the elastic modulus of carbon fiber is much larger than that of the matrix resin, when the carbon fiber and the matrix resin are at the same strain, the stress of carbon fiber will be much larger than that of the matrix resin. Therefore, the carbon fiber carries most of the applied stress load of the composite.

3. carbon fiber reinforced PA

Nylon (PA) as a common thermoplastic engineering plastics, has more than half a century of development, is the most widely used in engineering plastics, its products have played an important role in the automotive, machinery, petrochemical, textile, transportation, construction, electronics, metallurgy and other industrial fields.

Nylon (PA) itself has excellent performance, but it also has certain shortcomings, such as large moisture absorption, poor dimensional stability of products, strength and hardness as metal, etc., to a certain extent, affecting its application value. In order to overcome these defects, continuous carbon fiber reinforcement can be used to improve its performance.

Carbon fiber reinforced nylon this composite material fully reflects the performance advantages of the reinforcement and the matrix, the strength and rigidity are significantly improved than the unreinforced nylon, and the tensile strength of pure PA66 resin is increased by ten times. In high temperature environment, this composite material has smaller creep, good dimensional stability and better wear resistance.

4. Carbon fiber reinforced polyether ether ketone (PEEK) composite material

PEEK, as an emerging polymer, has been in the laboratory research and development stage in China until 2002, when domestic enterprises can be mass-produced. In recent years, the number of domestic PEEK production has steadily increased, and the product quality has reached international standards, which provides strong support for the development of fiber reinforced PEEK composites.

Carbon fiber reinforced PEEK composite is a kind of composite material with special engineering plastic polyether ether ketone (PEEK) as continuous phase resin matrix and carbon fiber (CF) as dispersed phase reinforcement. At present, continuous carbon fiber reinforced thermoplastic composites are mostly used in aerospace, satellite, military and other fields.