new blog

Since gaining attention after the COVID-19 , Pickleball has quickly become a popular sport, blending elements of tennis, badminton, and table tennis—a true "hybrid" game. According to Market. us, the pickleball market is projected to reach a scale of $4 billion over the next decade, with paddles accounting for 12% of the market share. The use of advanced composite materials in pickleball paddles has brought exciting advancements to these products, drawing significant attention from the composite materials industry.

Pickleball can be played both indoors and outdoors, offering versatility on tennis courts, basketball courts, or badminton courts. Notably, pickleball has been the fastest-growing sport in the U.S. for three consecutive years, with a cumulative growth rate of 223.5%, according to the Sports & Fitness Industry Association (SFIA). The Association of Pickleball Players (APP) reports that there are now 48.3 million active players, and Market.us estimates that the sport's market value will reach $1.5 billion by 2024.

In recent years, the pickleball market in Asia has also been rising rapidly. By 2024, Asia will have 21 pickleball federations under the Asian Pickleball Federation. The World Pickleball Championship (WPC) has announced 12 tournaments in the Asia-Pacific region for 2024, with 8 in Asia and 4 in Australia.

Types of Pickleball Paddles

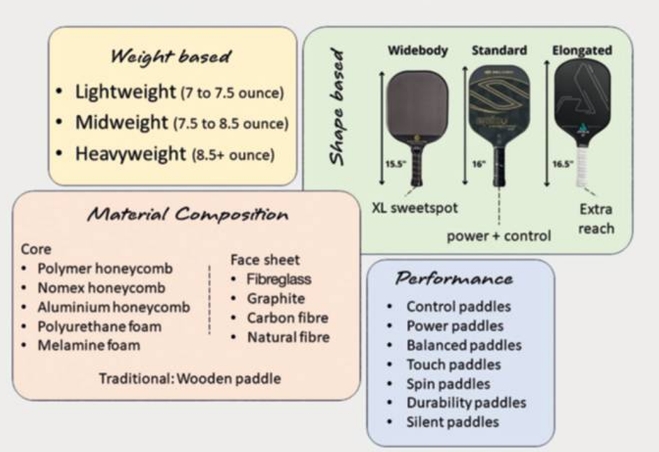

Pickleball paddles can be broadly classified based on four key parameters (as shown in Figure 1). While this is not an official classification by any association, it represents a general understanding of how products are segmented. Categorization by weight and size is self-explanatory, but material-based classification is particularly intriguing.

Paddles can be classified by their core or face materials. The most commonly used core is polypropylene (or polymer), a softer and lighter material with a density range of 60 kg/m³ to 110 kg/m³. This core strikes a balance between power and control. However, for players seeking greater hitting power, Nomex or aluminum cores are better choices.

Nomex cores also produce louder sounds during play, a concern for many players, prompting manufacturers to reconsider their core material options. Some manufacturers have shifted to using polyurethane or melamine foam as quieter alternatives, though these materials tend to be softer in performance.

Figure 1: Classification of Pickleball Paddles from a Manufacturing Perspective

Paddle Performance: Panel Materials

A key aspect of paddle performance is the panel material, which significantly affects paddle output. Most paddles use fiberglass panels, which offer better performance than wooden paddles and are more economical than carbon fiber or graphite options. Fiberglass panels also provide higher elongation, contributing to increased elasticity. Graphite-based panels are lightweight and sturdy, offering a balance between power and touch, though their brittleness can impact durability. For superior performance, T700-grade carbon fiber panels deliver excellent dynamic paddle performance but come at a higher cost.

Manufacturing of Composite Paddles

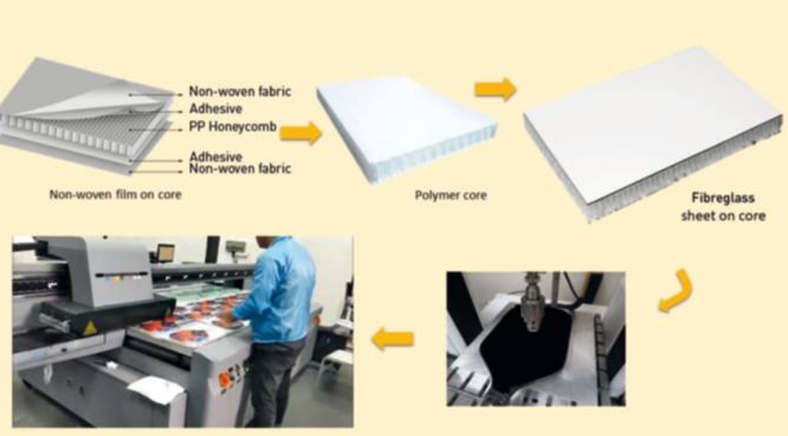

Currently, most pickleball paddles feature polymer cores and fiberglass panels. The core is made from thermoplastic polymer honeycomb material produced through a continuous online manufacturing process. Many manufacturers apply a nonwoven polyethylene terephthalate (PET) layer over the core to enhance bonding surface area (as shown in Figure 2). Fiberglass panels are applied to the core using various processes and stacking sequences, where many manufacturers differentiate themselves.

Typically, the most commonly produced paddles use high-thread-count 0/90 woven fiberglass fabric. This fabric is laid on the mold surface and impregnated with polyester resin. The choice of resin significantly influences paddle responsiveness (bounce) and power. After curing, these panels are bonded with compatible resins, often thixotropic resins to prevent resin flow and reduce voids. Manufacturers frequently add additives to increase resin viscosity for better bonding.

Some suppliers separately provide fiberglass sheets and cores for later bonding at their facilities. Japanese manufacturer Yonex uses carbon epoxy and glass epoxy prepregs, claiming to bond them with cores in an oven process.

Figer 2: Stages of Pickleball Paddle Manufacturing

If the core section is not initially cut to shape, it is trimmed after bonding using a CNC router or specialized cutting machine. The product is then cleaned with pressurized air, and a special powder coating is applied to the surface to create a controlled finish for optimal performance. These paddles are subsequently loaded onto flatbed UV printers, typically secured with Delrin fixtures to ensure precise alignment during printing.

The surface texture of the paddles is crucial for achieving spin and control. This process often involves applying a coating layer after printing to enhance grip and achieve the desired spin effect. Once printing is complete, edge guards are installed on the paddles. While many paddles use thermoplastic elastomers (TPE) for flexibility and bendability, some manufacturers opt for thermoplastic polyurethane (TPU) for better surface effects and durability. TPU performs well at low temperatures and maintains elasticity over time.

Most edge guards are applied using adhesive with heated fixtures. Paddles fitted with edge guards are then wrapped with rubber grips, similar to other types of paddles. Many manufacturers incorporate wooden components to enhance the three-dimensional feel of the grip. Finally, an end cap is installed, and the grip is heat-shrunk with low-micron polyethylene to prevent tampering and ensure long-term durability.

Each paddle undergoes a thorough inspection before leaving the factory. This inspection typically ensures the quality of the coating, appearance, and adhesion under high-brightness conditions. Some manufacturers also perform destructive testing on sample paddles from each batch.

Efforts to Reduce Noise

Complaints about noise on the court have drawn the attention of the USA Pickleball Association (USAPA). In response, the association introduced a "Quiet Category" standard for play in noise-sensitive locations. For context, here are some sound level comparisons: jet engine noise is 140 decibels, subway noise 95 decibels, loud conversation 90 decibels, noisy restaurant 85 decibels, highway traffic 70 decibels, normal conversation 60 decibels, and a quiet residential area 40 decibels. Occupational safety guidelines recommend continuous noise exposure below 85 dBA (A-weighted decibels) over an 8-hour period.

In contrast, the sound produced when a pickleball paddle hits the ball often exceeds 85 decibels and has a distinctive “pop” sound. The spectral characteristics of this noise are of even greater concern. According to USAPA standards, industry-compliant paddles generate frequencies between 1100 to 1200 Hz upon ball contact. This led USAPA to establish achievable thresholds for the “Quiet Category” standard.

In November 2023, OWL Sport, in collaboration with USAPA, announced the release of the first paddle meeting the "Quiet Category" standard. This paddle produces a sound pressure level below 80 decibels and frequencies under 600 Hz, a 50% reduction compared to the average paddle. According to OWL's official website, this achievement is credited to their proprietary Acoustene™ composite material. The company offers polypropylene paddles with core thicknesses ranging from 13 to 16 mm.

Leading paddle manufacturers are currently exploring various technologies to achieve quieter performance. The Pickleball Association is expected to issue further announcements in this area.

Natural Fiber Paddle Innovation

Technological advancements in natural fiber paddles should align with sustainability and eco-friendly initiatives. Some companies have begun investing in paddle panels made from natural fiber composites (NFC). These paddles are still in the early development stages. Figure 3 shows an example of such a paddle currently under development.

Figure 3: Natural Fiber Composites for Pickleball Paddles