new blog

Types of fibers used in composite materials

The structural properties of composite materials are mainly derived from fiber reinforcement. In composite materials, the fibers held in place by the matrix resin help to enhance tensile strength, enhancing the properties of the final part such as strength and stiffness, while minimizing weight.

Fiber properties are determined by the fiber manufacturing process as well as the ingredients and coating chemicals used in the process.

Glass fiber

Most of the fibers used in the composites industry are glass fibers. Fiberglass is the oldest and by far the most common reinforcing material in most end-market applications (the aerospace industry being an important exception), where it is used to replace heavier metal parts.

Glass fiber is heavier than the next most common reinforcement material, carbon fiber, is not as hard, but is more resistant to impact and has a greater elongation at break (that is, it stretches to a greater extent before breaking). Depending on the glass fiber type, filament diameter, coating chemical composition (called "sizing") and fiber form, a wide range of properties and performance levels can be achieved.

To make glass fibers, the raw material is melted and drawn into slender, highly ground filaments ranging from 3.5 microns to 24 microns in diameter. Silica sand is the main raw material, usually accounting for more than 50% of the weight of glass fiber. Metal oxides and other components can be added to the silica, and processing methods can be changed to customize the fibers for specific applications.

Continuous glass fibers are supplied in bundles called roving. Roving is usually a bundle of untwisted yarn that is wrapped like thread on a large spool. Single-ended roving consists of strands of multiple continuous glass fibers that extend along the length of the strand. Multiple roving contains longer, but not completely continuous, strands that are added or dropped in a staggered arrangement during winding. A yarn is a group of yarn twisted together.

Electrical glass fiber, or E-glass fiber, is so named because its chemical composition makes it an excellent electrical insulator, particularly suitable for applications that require radio signal transparency, such as aircraft radomes, antennas, and printed circuit boards. However, it is also the most economical glass fiber for composite materials, providing enough strength at a relatively low cost to meet performance requirements in many applications. It has become the standard form of glass fiber, accounting for more than 90% of all glass fiber reinforcement materials. At least 50% of the E-glass fiber consists of silicon oxide; Allowances include oxides of aluminum, boron, calcium, and/or other compounds, including limestone, fluorite, boric acid, and clay.

When greater strength is needed, high-strength glass fibers, first developed for military applications in the 1960s, are an option. It has several names - S glass fiber in the United States, R glass fiber in Europe, and T glass.2 in Japan. Glass fiber, its strand tensile strength is about 700 ksi, tensile modulus up to 14 Msi. The content of silicon oxide, alumina and magnesium oxide of S-glass fiber is significantly higher than that of E-glass fiber, and it is 40 ~ 70% stronger than E-glass fiber.

When the temperature is increased from ambient temperature to 540°C, the tensile strength of E-glass fiber and S-glass fiber is reduced by half, although both fibers still exhibit good strength over this elevated temperature range. Manufacturers constantly adjust the formula of S glass fiber. For example, AGY Holding Corp. (Aiken, SC, US) introduced S-3 UHM (Ultra High Modulus) glass fiber a few years ago. The upgraded S-3 glass fiber has a tensile modulus of 14,359, which is higher than S-glass fiber glass and 40% higher than E-glass, due to improved fiber manufacturing as well as proprietary additives and melt chemistry.

Although glass fibers have relatively high chemical resistance, they are eroded by leaching when exposed to water. For example, an E-glass filament with a diameter of 10 μs typically loses 0.7% of its weight when left in hot water for 24 hours. However, the rate of erosion slows significantly because the leached glass fibers form a protective barrier on the outside of the filaments; After 7 days of exposure, the total weight loss was only 0.9%. To slow down erosion, moisture-resistant adhesives, such as silane compounds, are used in the fiber manufacturing process.

Corrosion-resistant glass fibers, known as C glass fibers or E-CR glass fibers, are more resistant to acidic solutions than E glass fibers. However, E-glass fiber and S-glass fiber are more resistant to sodium carbonate solution (alkali) than C-glass fiber. Boron-free glass fibers are comparable in performance and price to e-glass, showing higher corrosion resistance in acidic environments (similar to E-CR glass fibers), higher elastic modulus, and better high-temperature performance. In addition, removing boron from the manufacturing process has less impact on the environment, which is a decisive advantage.

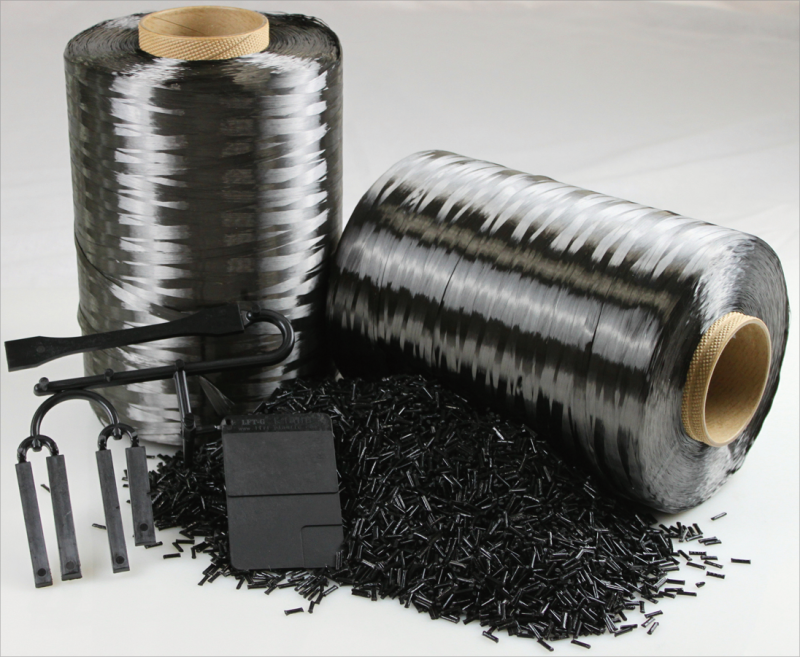

Carbon fiber

Carbon fiber is by far the most widely used fiber in high-performance applications and is produced from a variety of precursors, including polyacrylonitrile (PAN), rayon, asphalt, and bio-based carbon-rich precursors such as lignin or bio-based PAN. The precursor fibers are chemically treated, heated and stretched, and then carbonized to form high-strength fibers. The first high-performance carbon fibers on the market were made from rayon precursors. Pan-based carbon fibers have long replaced rayon in structural applications, but rayon's "dogbone" cross-section and high temperature properties often make it the fiber of choice for ablating carbon/carbon (C/C) composites in heat shields. Pan-based carbon fiber is the most widely used carbon fiber. They offer a range of amazing properties, including excellent strength (1000 KLB/sq. inch) and high stiffness. Asphalt fibers are made from petroleum or coal bitumen and have high to extremely high stiffness and low to negative axial thermal expansion (CTE-thermal expansion). Their CTE characteristics are particularly useful in spacecraft applications that require thermal management, such as electronic instrument housings.

Although carbon fiber is stronger than glass or aramid fiber, because of its electrical conductivity, carbon fiber is not only poor impact resistance, but also can cause galvanic corrosion in the metal it contacts. Manufacturers overcome the latter problem by using a barrier material or veil layer (usually fiberglass/epoxy) during the laminate lamination process.

The basic fiber form of high-performance carbon fiber is a continuous fiber bundle called a tow. The carbon fiber bundle consists of thousands of continuous, untwisted filaments, the number of filaments represented by a number by a "K", which means multiplied by 1000 (for example, 12K means the number of filaments is 12000). The tow can be used directly for processes such as fiber winding or pultrusion, or can be converted into one-way tape, fabric, and other enhanced forms.

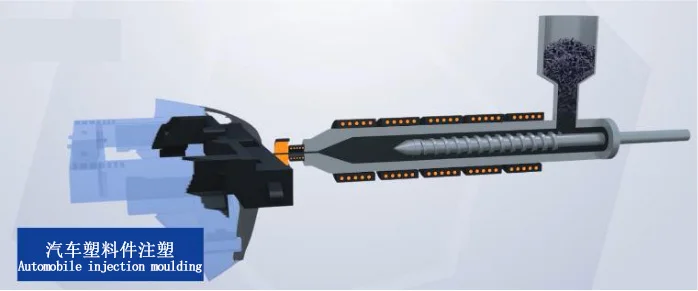

Injection molding

Also known as injection molding, it is the thermoplastic resin raw materials (pellets) such as carbon fiber reinforced nylon and polycarbonate that are heated and melted and injected into the mold cavity (gap). This is a molding method suitable for short cycle and complex shape molding.