new blog

In the new energy vehicle materials industry, polymers encompass plastics, rubber, silicone materials, and composite fiber materials such as carbon fiber. To avoid safety hazards associated with high-voltage systems, materials for new energy vehicles must not only be heat-resistant but also flame-retardant.

Therefore, Xiamen LFT has introduced a flame-retardant polyamide solution targeting manufacturers of electric vehicle powertrain components and electric vehicle battery applications, helping to ensure the safe and efficient operation of electric motors.

Nylon 66, due to its excellent heat resistance, chemical resistance, strength, and ease of processing, has been widely used in the automotive industry. It is now applied in nearly all automotive components, such as electrical parts, body components, etc. Vehicle components include air horns, air conditioning hoses, cooling fans and their housings, intake pipes, brake fluid tanks, and filler caps. Body parts include fenders, rearview mirror frames, bumpers, dashboards, luggage racks, door handles, wiper brackets, seat belt buckles, and various interior decorative parts. Automotive electrical components include electric windows, connectors, storage boxes, and cable ties.

PA6

PA6 has excellent mechanical properties, rigidity, toughness, wear resistance, and mechanical shock absorption. It also has good insulation and chemical resistance. It is widely used in automotive components, electronic and electrical parts, and many other fields.

Traffic Signal Base

Due to exposure to light sources, the working environment is relatively high, and it is also located in areas that may be subject to impact. Therefore, there is a certain demand for impact resistance and toughness. Using PA6 can address these issues. Similarly, in automotive lighting, standard screws or brackets used in headlamps are also commonly made from PA6 +GF, which is a routine practice in the automotive industry.

Automobile Chassis Parts

Due to exposure to light sources, the working environment is relatively high, and it is also located in areas that may be subject to impact. Therefore, there is a certain demand for impact resistance and toughness. Using PA6 can address these issues. Similarly, in automotive lighting, standard screws or brackets used in headlamps are also commonly made from PA6 +GF, which is a routine practice in the automotive industry.

Charging Pile Enclosure

In recent years, research into materials for automotive charging piles has been progressing rapidly, and some consensus has been reached. Since charging piles may appear in various locations in daily life, the performance requirements are high. In outdoor environments in northern regions, the material needs to withstand low temperatures. To prevent sudden fires, the flame retardant properties need to be good. To ensure safety, the material should be non-conductive. Additionally, due to exposure to various natural conditions, the material must have excellent anti-aging properties. Furthermore, ensuring the robustness and ability to withstand harsh environments is of utmost importance. PA is a translucent or opaque milky-white particle with the best overall performance, whether in terms of mechanical strength, rigidity, shock absorption, wear resistance, good electrical insulation, or chemical resistance, making it one of the materials chosen for charging piles.

Battery Enclosure

Currently, battery enclosures are generally made from PA materials, with PA6 being the most commonly used. Flame retardancy is also an important reference for selecting materials for new energy vehicle battery enclosures. Unmodified PA6 typically has an oxygen index of only 20% to 22%, and its flame retardant grade only reaches UL 94 V-2, which is insufficient to meet the stringent flame retardant requirements of new energy vehicles.

PA66

Compared to PA6, PA66 offers better mechanical strength, stiffness, heat resistance, wear resistance, and creep resistance. However, its impact strength and mechanical damping performance are reduced. It is widely used in industries such as automotive, drones, and electronics.

Connector Electronics Connector Manufacturing Requirements

Modified nylon for manufacturing connectors requires high flowability, high toughness, high temperature resistance, and ease of molding. The suitable materials are as follows:

Terminal blocks

General-purpose flame-retardant PA6/PA66.

Coil Frame

Coil frames require modified nylon with high strength, high toughness, and high temperature resistance.

PA12

PA12, due to its high content of toughening agents, combines the properties of both polyamide and polyolefin. Its outstanding characteristics include a high decomposition temperature, low water absorption, and excellent low-temperature performance. It is mainly used in automotive fuel lines, instrument panels, throttle pedals, brake hoses, as well as in the silencing components of electrical appliances and cable sheaths.

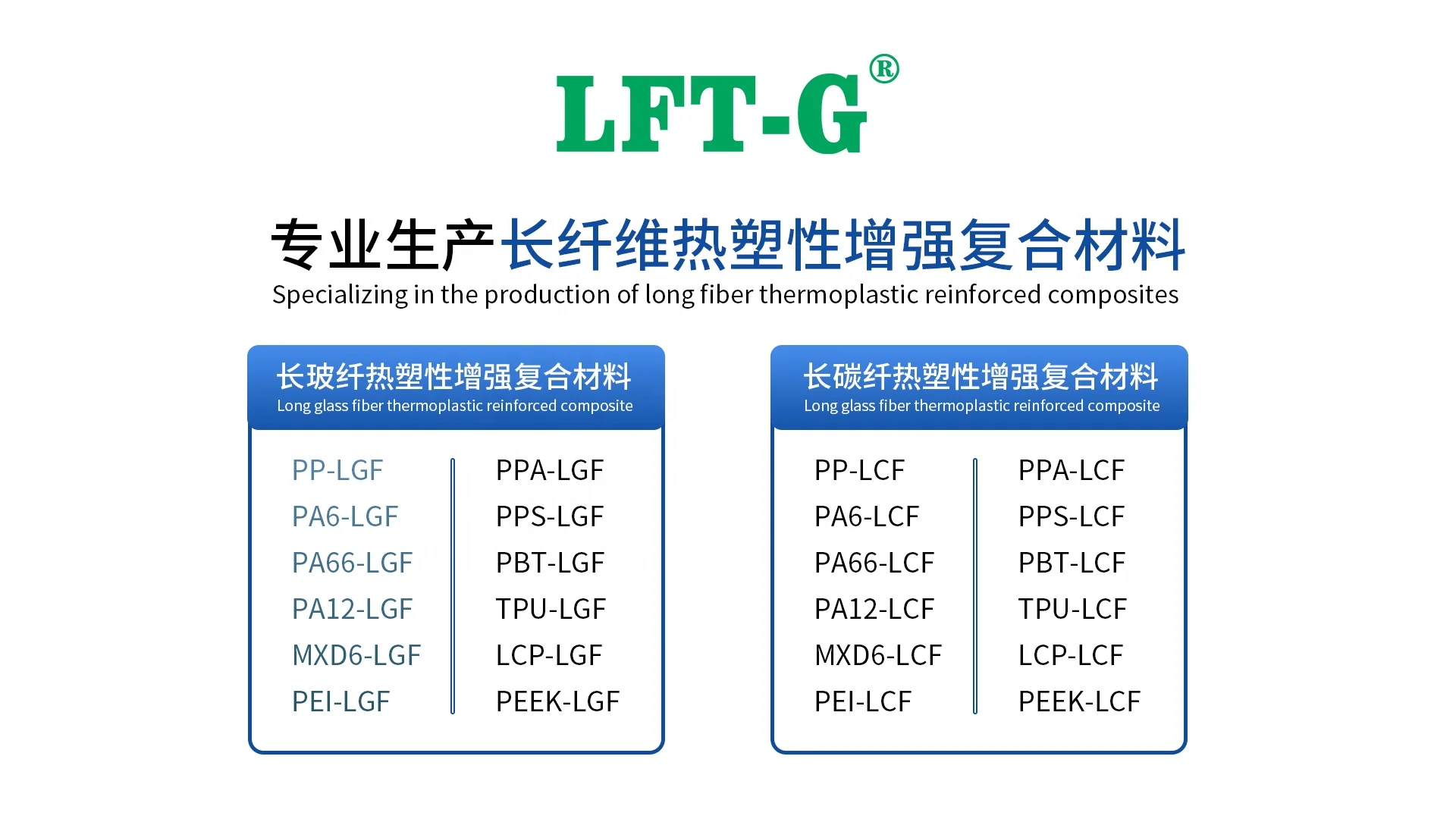

Long Glass Fiber Reinforced PA6

Long glass fiber reinforced PA6 has many advantages comparable to metal, making it suitable for the production of complex automotive module products. For example, in the case of the instrument panel beam, the beam directly connects to the vehicle body, bearing and transmitting the load of human-machine interface equipment and decorative components. It also forms part of the cockpit safety system along with other safety components, directly affecting the vehicle's handling and safety.

Glass Fiber Reinforced PA66

Glass fiber reinforced nylon materials are known for their high strength, excellent wear resistance, corrosion resistance, and good electrical insulation properties. They are also widely used in the components of new energy vehicle charging systems. Classic application examples include battery boxes, AC motor housings, and electric vehicle charging systems.

Glass fiber reinforced PA66 is extensively used in the automotive industry for components such as engine hoods, doors, instrument panels, and seats. Common ratios of glass fiber reinforcement for PA66 include: PA66 + 10% glass fiber for automotive interior parts, and PA66 + 30% glass fiber for automotive exterior parts.

Glass fiber reinforced PA66 can also be used for electronic throttle control housings—components that provide acceleration/deceleration signals based on the position of the pedal.