new blog

From the ancient Egyptian dynasty of more than 4,000 years B.C. until the second industrial revolution in Europe in the 19th century, the history of furniture is actually the history of wood. Modern furniture appeared in the late 19th century, relying on the two industrial revolution brought about by the leap in productivity, the furniture manufacturing industry in more than a century of development time has greatly improved the production efficiency and capacity, and continue to give birth to a new production process.

Currently on the market non-wood furniture materials can be roughly divided into five categories: metal materials, inorganic non-metallic materials, natural organic materials, synthetic organic materials, composite materials. With the continuous upgrading of the development of new carbon materials technology, carbon fiber composites in the future of furniture applications are very broad prospects.

Lightweight furniture design, is to reduce the physical weight of the furniture product itself and the sense of visual weight for its main purpose, at the same time, carbon fiber composite materials with the integration of furniture design is also for the designers to ignite the spark of creativity. The development and application of carbon fiber composite materials for furniture lightweight design provides more possibilities, including optimization of carbon fiber composite bearing structure configuration, molding process of lightweight, and furniture styling design to create a sense of lightweight furniture.

Ultra-light weight that is difficult to achieve with traditional materials

Compared with traditional materials, the biggest characteristic of carbon fiber composite material is its light weight, its density is only 1/5 of steel, 1/3 of titanium alloy, and even lighter than aluminum alloy and FRP. Furniture made of carbon fiber composite material, on the one hand, has a super-light quality, lightweight and dexterous, easy to combine, move and transport, and on the other hand, novel and peculiar, easy to let the consumer produce a visual sense of pleasure.

In the Japanese designer Kiyomi Suzuki design back chair (Cherche Midi), we can see her carbon fiber composite material "light" the perfect interpretation of this characteristic.

Chairs designed by Kiyomi Suzuki

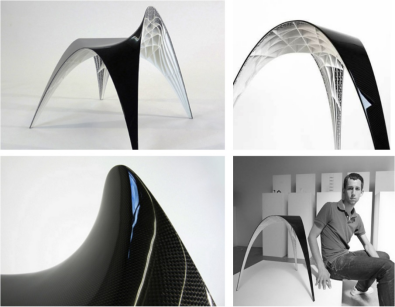

The weight of the chair is only 960 g. The design is inspired by the dark shadows of the sea luxuriant flowers swaying in the breeze, and the product ultimately highlights the lightness of the body in terms of sensibility, while allowing the female user to maintain an elegant posture. The Gaudi Chair designed by Bram Geenen, also a young designer from the Netherlands, is only 1kg.

Chairs designed by Bram Geenen

These two designs of chairs are not because of the ultra-light quality and lose the basic use of the function, but is more extreme and simple will be the charm of the material itself exudes, which may be carbon fiber composite material is different from the charm of traditional materials.

Perfect presentation of the load-bearing structure

Carbon fiber furniture design to achieve lightweight, in addition to the excellent material properties of the material itself, but also thanks to the flexible and versatile structural configuration design.

First of all, the traditional reinforcement, rounded corners and the use of sandwich structure and other efficient load-bearing processing methods, you can use less material to get the required strength and stiffness, and through the topological optimization of the mechanical properties of carbon fiber composite materials in all directions of force, and further lightweight furniture products.

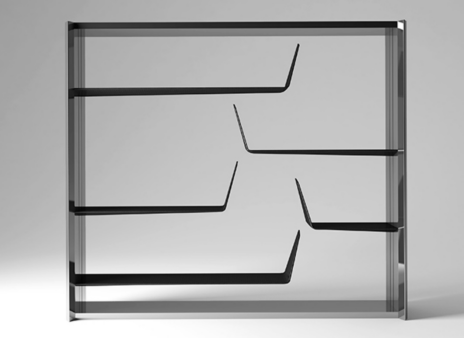

Such a form of furniture components not only saves material but also reduces the space occupied by the furniture. Furniture designer Terence Noodgate worked with Formula 1 designer John Barnard to create a table with ultra-thin components (Surface Table).

Tables designed by John Barnard

As we can see, the carbon-fiber reinforced resin tabletop is only 2mm thick, and from the side horizontal view we can barely see the frame of the table, but it is strong enough to support up to 3m of tabletop. Similarly, in another Stealth Table design from Australia, the edge of the table is only 6mm thick.

Carbon Fiber Composites Stealth Table

From these two tables, we can feel the unique sense of quality and technology brought by the smooth and delicate lines of the ultra-thin components.

By optimizing the reasonable design of the force structure, using the anisotropy of the mechanical properties of carbon fiber composites, under the condition of satisfying the design of the shape, let the direction of the mechanical properties of the material be arranged along the advantageous force transmission path of the structure to achieve the design of equal strength or equal stiffness, which can make the mechanical properties of the carbon fiber composites to maximize the advantages of carbon fiber composites, so that each gram of the material's load-bearing capacity can be utilized more efficiently. Such as the designer Design-Jay designed table, the legs are very slim, desktop ultra-thin, but the use of such a thin carbon fiber materials do not have to worry about whether it is solid and reliable, the designer through the calculation of data and experimental testing, in accordance with the material's advantage of the mechanical properties of the structure along the path of the force transfer arrangement to maximize the reduction of the material used, there is no trace of redundancy, the structure is very solid. From the overall point of view is a simple table, but the side view is only a few simple lines, giving people a sense of light and delicate.

Carbon Fiber Composite Table by Design-Jay

Realization of Very Large Scale Cantilevers

Carbon fiber composites have much higher tensile strength and bending strength than ordinary furniture materials. By utilizing this property, furniture parts can be extended in a large scale within a certain space without bending.

In the 2009 Tokyo Fiber exhibition, Japan's modern architect Jun Aoki showed his design of large-scale cantilevered spotlight Thin Beam Lamp, the lamp body is made of Japan's Toray production of carbon fiber production, which cantilevered light plate length of 6 meters;

Carbon fiber composite light panel designed by Jun Aoki

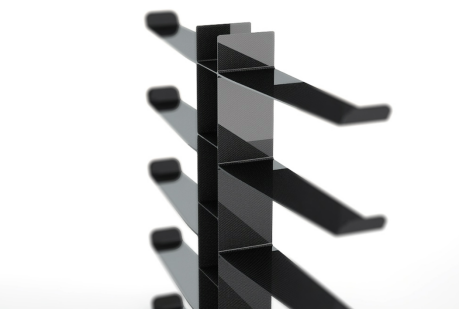

There are also similar ones, such as the bookcase (Aliante) launched by Olympus FRP of Italy, also made of carbon fiber composite material, the shelves of each layer of the bookcase to the vertical center of the axial expansion of the two sides, up to 2.7 m. Such two pieces of furniture, both through the appropriate expression of the material characteristics of the large-scale cantilever to provide users with a greater range of use of the space. The two pieces of furniture are expressed through the appropriate material feature, the oversized cantilever, providing the user with a greater range of space.

Bookshelf by Olympus FRP

Carbon Fiber Composite Bookcase

Flexible and Variable Curve Modeling

In recent years, furniture products can express the development of modern flavor with the times, fit the aesthetic feeling of modern people become more and more young people's needs. More delicate and unique design, more detailed craftsmanship, the use of materials more and more trendy fashion, shape form light and dynamic and so on are many elements of modern furniture design requirements, showing the modern people on the spiritual pursuit of furniture design and aesthetic characteristics.

Furniture made of carbon fiber composite materials, on the one hand, easy to transport and move, flexible and easy to knit the unit structure, flexible line modeling, colorful color performance and a series of modern aesthetic concepts in line with the design features can be shown through the reasonable application of carbon fiber composite materials.

Carbon Fiber Composite Chair

About Xiamen LFT composite plastic Co., Ltd.

Xiamen LFT Composite Plastic Co.,LTD was established in 2009, is a brand-name global suppliers of long fiber reinforced thermoplastic materials integrating product research & development(R&D), production and sale marketing. Our LFT products have passed the ISO9001&16949 system certification and have obtained lots of national trademarks and patents, covering the fields of automotive, military parts and firearms, aerospace, new energy, medical equipment, power wind energy, sports equipment, etc.